Limit switches are special devices that allow you to disconnect electrical power from the actuator at the right time. Another name for these devices is “switch-type trailer”, which is explained by the specifics of mounting their holders on the final sections of movements. To understand the features of the work, it is important to familiarize yourself with the design of this type of switching products.

Design features

The limit switch used in electrical circuits is an electrical device that in its functions resembles a conventional switching device. The difference from the usual products is the specifics of the application and the related design features. Since they are triggered only at the final displacement site, a special stock is provided on their casing, fixing the moment of reaching the control position.

The modern limit switch is equipped with non-contact means for determining the position, including inductive or capacitive type sensors.

Technologically advanced models with inductive and capacitive sensors greatly simplify installation and increase the reliability of actuators, reducing their cost and extending their service life.

Areas of use

Known types of limit switches are in demand in various fields of human activity. According to their functional orientation, they are divided into the following types:

- limit switches protective action;

- devices for individual use.

The first are mounted in order to protect mechanisms and people from actions not provided for by the device operating rules. For example, elevator mechanisms are not set in motion until their door curtains are completely closed. Their main purpose is to ensure human safety when using various mechanisms.

Individual use devices are used in household appliances or industrial units where it is required to fix a certain moment of movement. When the refrigerator doors are closed, the lighting in it is turned off by a contact switch, and when opened, it turns on again.

In the general case, the field of application of the devices is all those places where it is necessary to limit the movement to some kind of framework. One option is to control the position of the valve of the devices, blocking unacceptable mechanical movements.

When installing the trailer in the control chain of the swing door, for example, it is fixed on the screws inside the cabinet built into the wall. When closed, the door casing presses the control button, opening the electrical circuit for lighting the interior spaces. When it is opened, the button contact is restored and closes the working circuit, after which the lamp lights up.

Functional classification

According to the principle of their action, limit switches are divided into three main groups:

- contact trailer electric;

- contactless devices;

- magnetic devices.

The operation of mechanical switches is based on the direct action of the tip on the actuator of the electric drive, interrupting the supply of power due to direct contact with it. An example of contact limit switches is the mechanisms that are triggered when a car door or garage door is closed.

A feature of contactless devices is the transfer of energy to the sensors of the following types:

- inductive end sensors;

- capacitive sensors;

- ultrasonic and optical sensors.

Taking into account the type of sensor built into the switches, they are mounted in one or another actuating circuit.

Magnetic Limiters

A special place is occupied by sensitive devices operating under the influence of a magnetic field. These products, otherwise called reed switches, replace the mechanical models of switches. Their contacts from a ferromagnet placed in a glass flask close or open when placed next to a permanent magnet. Due to the simplified design, the dimensions of this device are very small, so that it is easily mounted in the gap of the controlled circuit.

The contacts in it are normally closed, as well as normally open or switched, and the choice of a particular type depends on the nature of the movement, including the reverse mode.

When installing magnetic reed switches, their polarity must be taken into account. If you confuse the poles - they will not work.

Limit magnetic switches are widely used in the design of sliding gates. Some models are part of the executive unit of the security alarm, mounted at the entrance to the house. Often these devices are installed in modern furniture for controlling indoor lighting, for example. The built-in furniture light switch is the most convincing example of their effectiveness. The absence of mechanical contacts in such a design is its indisputable advantage, which helps to extend the life of the product.

Connection order and specifics

Although the end microswitch itself is simple enough, it can be used in electronics-rich processing equipment. It follows that it must be connected by a specialist with experience who is well versed in switching circuits of electronic components.

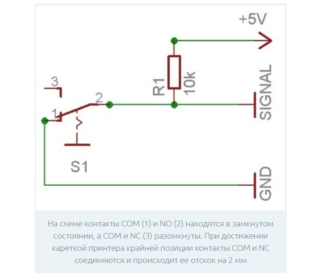

A typical example of such a connection is the installation of a mechanical switch in a typical 3D printer, which requires fixing the extreme position of the carriage. The mounted switch has 3 contacts with the following designations: COM, NO, NC. In the open state, the first and third terminals have a voltage of +5 Volts (while the second contact is reliably grounded). When the movable carriage reaches its extreme position between COM and NC, a connection appears, after which it is fixed and rebounds by about 2 mm.

Such a sensor is connected via two conductors in red and black insulation. When installing another type of switch (with indicator), a more complex circuit is used, in which another conductor is provided - in green insulation. When the micro-switches of the push type are triggered, the LED lights up in the printers and a characteristic click is heard. Its connector, located on the switching board, has special designations:

- the red wire is marked as V (+5 Volts) and serves to connect the corresponding voltage;

- black conductor leads to point G (or ground);

- S (signal) is selected for the green bus.

The same signs appear on the connector of the optical limit switch, which more accurately fixes the position of the carriage.

It works completely silently, reaching the extreme position is accompanied by LED indicators. Its disadvantages include the possibility of failures with strong dust or exposure to direct sunlight.

Instructions for connecting magnetic sensors are given in the passport for furniture sets with limit switches in their design. The diagram attached to it usually indicates the attachment point of the plastic case with the switch operation control key.For a door located in the middle of the cabinet, the appliance is installed in such a way that it does not interfere with the normal shutter of the other door leaf.

Limit Switch Marking

Microswitches and microswitches, regardless of their characteristics, are specifically labeled. After decoding it, it is possible to obtain all the information about each model of the limit switch. If a record like “VU222M” is found on it, this indicates a switch of the corresponding series. As an example, we decode the marking of a widespread product of the brand VP 15M4221-54U2. It means that in its design there is one movable element of the series 15, as well as one closing and opening contact.

All switching elements of this series are controlled by a roller pusher integrated in the housing.

The degree of protection on the drive side of the structure corresponds to IP54, and the “U” symbol indicates climatic modification. The next figure 2 is the product placement category, which corresponds to TU U 31.2-25019584-005.

Leading manufacturers

Many companies are involved in the production of terminal sensors. The leader recognized by all is the German company Sick, which is considered the main manufacturer of products of this class. Another well-known company Autonics is engaged in the production of proximity switches of inductive and capacitive type. Inexpensive sensors of the same class and of high enough quality are also produced by a Russian company called TEKO. Its products are characterized by a high degree of tightness (IP68), so that they can be used in especially hazardous environments.

The Promfactor limit switches from Ukraine have also proven themselves in the Russian markets. This manufacturer produces switching devices under the designations VP, PP and VU. The warranty issued for all these products is 3 years.