In the market of electrical materials, in addition to wires with standard Russian marking, cables with the AWG designation are often found. Conductors of this class are designed to solve specific problems and have individual technical characteristics.

American wire gauge

The abbreviation AWG itself is of American origin and means American Wire Gauge, which translates as "American wire gauge." It does not indicate the diameter of the inner cores in millimeters, which is customary for us, but the number of cable runs through the molding machine in the production process.

For example, the 24 AWG wire has a smaller core diameter than the 22 AWG marking conductor, since in the manufacture of the first cable passed through the molding machine 24 times, and the second only 22.

Calibration, in accordance with the presented standard, varies slightly with the standard range of diameters in millimeters. Recalculation into the usual sizes of a single-core conductor and a multicore is performed according to different formulas.

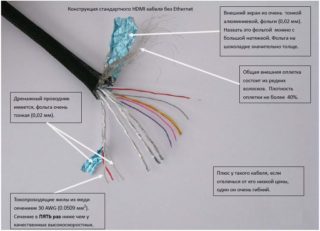

The AWG standard itself does not only apply to power cables and wires used in arranging electrical wiring. It is also used in the digital industry, for example, for marking HDMI and USB cables, twisted pairs, etc.

Where did the AWG marking come from?

In their form, cable conductors are similar to ordinary copper wire.

In the United States, wire was previously produced by the principle of drawing (drawing). To do this, the workpiece was passed through the rollers of the machine. For example, there is a workpiece with a cross-sectional index of 12 mm. To reduce its diameter to the required, the wire was dragged through the calibration hole a specific number of times, as a result of which it was pulled, the length index increased, and the diameter index decreased. So from the 12th diameter it was possible to make the 10th or 8th.

Each subsequent pulling procedure lowered the cross section and added one to the AWG value. At the start of the process, the workpiece with the largest caliber AWG 0 is used (matching the thickest cable). With one wire pull, the value AWG 1 will be obtained. If the workpiece passes through the machine two times, then the value AWG 2 will be obtained and so on.

Largest calibers larger than AWG 0 are designated as AWG 00, AWG 000, etc.

Such marking is mirror in relation to the Russian one. We got used to the fact that the larger the number, the larger the cross section of the conductors. Here, everything is different - the larger the caliber, the smaller the diameter of the conductors.

In which countries do they use

In addition to the creators, the presented standard is actively used by Japan and China.

European countries, countries of the former CIS and Russia use a different measurement system - mm2.

In addition, in the USA, such a measuring unit as a millimeter is not used at all. Literally in every technical field an inch is used, denoted as inch.

Cable Applications

AWG marking cables in the common people are called twisted pair, since their cores are braided in pairs and form a solid wire. There are many industries that use such cables.

The main ones are:

- Electrical supply of outlet networks and diode lamps in rooms for domestic and industrial use. Often the current in such highways does not exceed 24V, and the most common voltage is 12V.Such a scheme makes it possible to reduce energy costs and is safer than 220V lines.

- Arrangement of wiring in the field of telephony and communications, for example, as lines for connecting to the Internet or local type networks.

- In fact, all electrics in vehicles are represented by AWG marking cables with different calibers. The most commonly used 23 AWG twisted pair is a longitudinal section, where the conductor can be either single-core or multi-core. Battery power is supplied to the starter and motor using thicker wires marked 16 AWG.

- Music centers and televisions also use these conductors. For example, in headphones and microphones, twisted pair 22 or 24 AWG is used, the cross-section in mm of which will be indicated below.

- Cables with the smallest caliber, less than 26 AWG, are used in car alarms, temperature sensors of gas or electric boilers, as well as in automatic fire extinguishing systems. They can not withstand high voltage, but for networks with a small amount of current are the best option. For example, 28 AWG wires are used extensively in automotive airbag contactors. 30 AWG cable is commonly used in Internet connection boxes.

It is strictly forbidden to connect low-current type wires to a stationary 220V / 380V network. This will inevitably lead to a short circuit.

All of the above branches of the use of wires are key, in practice there are significantly more of them. Non-standard gauge conductors that perform data transfer functions are often found in these industries.

Low-current networks do not pose a threat to humans and animals. The impact of such a current is literally not felt by the human body, such networks are the safest and are used in astronautics and other technical industries. Even during open contact with bare veins, a person does not feel an electric shock, therefore, repair work can be performed without disconnecting the network.

Fiber optic cables manufactured using US technology and marked as 24 AWG are actively used (in mm it is equal to 0.644). Such networks extend both externally and underground. They are designed to transmit data at high speeds.

Cable design and composition

In accordance with the task to be solved, conductors marked as AWG may have different calibers and the type of external winding.

In accordance with the task to be solved, conductors marked as AWG may have different calibers and the type of external winding.

This primarily concerns single-core conductors with different thicknesses of the base and an external insulating layer of foamed polypropylene. The core can be wicker and can be composed of several layers of aluminum or copper cores twisted in a spiral way. Their thickness indicator directly affects the degree of current resistance - the larger the number of cores and the indicator of their thickness, the weaker the resistance and the loss per meter of the conductor will be. Also, this value affects the degree of metal heating at increased loads. Large-gauge cores are more resistant to heating, which significantly extends the life of common highways.

AWG Stranded Wires

Stranded wires in their design are somewhat more complicated, so it is extremely difficult to make the correct calculation comfortable for their load. It is necessary to build on the characteristics of one core and calculate the ratio.

The cables themselves, the caliber of which is indicated by the number in front of the abbreviation AWG, can have a cylindrical shape or the shape of a triangle woven into a solid rod. Due to the elasticity of the metal, the wire can be twisted at different angles, which is very convenient for installation work in hard-to-reach points, for example, wall cable channels.

The insulating layer of polypropylene or PVC also has high flexibility and excellently tolerates mechanical stress during sifting of the soil or deformation of part of the highway. The insulation is absolutely dielectric, so even when connecting the cable bundles with each other, a short circuit is excluded.

In separate twisted pairs of optical fiber, excluding the standard sheath, a reinforcing thread is located between the core and the insulating layer, which is twisted in a spiral. It gives strength to products even during twisting. Such insulation prevents stretching of the wires, constantly returning the rod and the outer layer to an acceptable level.

A separate class should include television cables for transmitting a signal from an antenna or amplifier. These conductors have a copper core, which is sealed in a polyethylene foam. From the center of the cable to the edge is a foil sheath, which is responsible for the delivery of negative particles. The outer layer is PVC insulation, tightly fitting the entire product. The conductor is assembled using special metal adapters with a tight fitting device. They securely fix the wire and guarantee contact accuracy.

Copper conductors have greater strength than aluminum. Therefore, their operational life is longer. They are less susceptible to wear from mechanical influences, but the cost of such products is higher.

Convert AWG cable and wire to millimeters

In order not to recalculate the caliber of each conductor by the diameter in square millimeters on the calculator, you can resort to using the table with ready-made numbers:

| Caliber | Diameter mm | Cross section mm2 |

| 0000 | 11,68 | 107 |

| 000 | 10,40 | 85 |

| 00 | 9,26 | 67,4 |

| 0 | 8,25 | 53,5 |

| 1 | 7,34 | 42,4 |

| 2 | 6,54 | 33,6 |

| 3 | 5,82 | 26,7 |

| 4 | 5,18 | 21,2 |

| 5 | 4,62 | 16,8 |

| 6 | 4,11 | 13,3 |

| 7 | 3,66 | 10,5 |

| 8 | 3,26 | 8,37 |

| 9 | 2,90 | 6,63 |

| 10 | 2,58 | 5,26 |

| 11 | 2,30 | 4,17 |

| 12 | 2,05 | 3,31 |

| 13 | 1,82 | 2,62 |

| 14 | 1,62 | 2,08 |

| 15 | 1,45 | 1,65 |

| 16 | 1,29 | 1,31 |

| 17 | 1,15 | 1,04 |

| 18 | 1,02 | 0,82 |

| 19 | 0,91 | 0,65 |

| 20 | 0,81 | 0,51 |

| 21 | 0,72 | 0,41 |

| 22 | 0,64 | 0,32 |

| 23 | 0,57 | 0,25 |

| 24 | 0,51 | 0,20 |

| 25 | 0,45 | 0,16 |

| 26 | 0,40 | 0,12 |

| 27 | 0,36 | 0,10 |

| 28 | 0,32 | 0,08 |

| 29 | 0,28 | 0,06 |

| 30 | 0,25 | 0,05 |

| 31 | 0,22 | 0,04 |

| 32 | 0,20 | 0,03 |

| 33 | 0,18 | 0,02 |

| 34 | 0,16 | 0,0201 |

| 35 | 0,14 | 0,016 |

| 36 | 0,12 | 0,012 |

| 37 | 0,11 | 0,01 |

| 38 | 0,10 | 0,007 |

| 39 | 0,08 | 0,006 |

| 40 | 0,07 | 0,005 |

In the USA, for the Internet connection, the most commonly used wires are 22 AWG marking, the cross section in mm of which is 0.644. The maximum caliber for industrial applications is unlimited, but the most popular are 4 AWG and 8 AWG marking conductors.

Calculation formulas

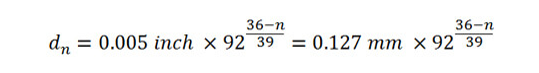

The formula for converting calibers to millimeters is as follows:

The rate of 0.005 inches, when converted, is 0.127 mm. The value of n is the nomenclature of the caliber. The presented formula is valid only for solid wires of cables and wires.

The values “36”, “39” and “92” are present in the formula for a reason. At the end of the 90s, caliber 36 met the AWG index, whose diameter is 0.005 inch. In those years, it was the thinnest wire. The thickest cable was AWG 0000 caliber. The ratio between the smallest and largest diameter is exactly “92”.

The calibration range, starting with the AWG 36 marking, consists of 38 consecutive calibers and the ratio between them is a constant value. Between adjacent calibers, the ratio is 1.1229. This figure is the root of the 39th degree out of 92.

For large gauges, the role of “n” is a negative indicator - (m-1).

Rules of thumb

The sixth level of the ratio of the diameters of two adjacent AWG calibers is extremely close to 2 (2.005), which dictates the following rules:

- Doubling the cable diameter reduces the caliber by 6 marks.

- Doubling the cable cross-section entails a reduction in caliber by 3 units.

- Lowering the caliber by 4 units doubles the melting current of the cable.

Lowering the caliber by 10 units increases the area and mass by about 10 times and reduces the degree of resistance also by about 10 times.

terms of Use

AWG cables have the same insulating layer and outer sheath as traditional metric wires. When installing products and their operation, you must follow the basic rules:

- During the laying of the line in the ground, it is impossible to carry out the installation of conductors without a protective corrugation or asbestos sleeve.

- When tensioning the wires between the supports, it is necessary to use guide cables that release tension from the conductors.

- If the cable is laid at the bottom of the pond, its connections must be carefully insulated with foamed polyethylene.

You can not apply voltage to the conductors more than its specific value - it is fraught with overheating and short circuit.