Wago wire connector - a special spring clip (retainer, terminal block) used for reliable connection of two or more conductors. Due to the large number of advantages over other types of clamps, wagons are gradually gaining more and more popularity, displacing screw terminal blocks, caps and twists.

Distinctive features of Wago

Compared to other similar devices, Wago terminal blocks have a number of the following features characteristic only for them:

- a wide variety of models, both for household electrical circuits and production power lines;

- the presence of clamps for single and multiple use - in individual models of such terminal blocks, if you need to dismantle or repair a separate section of the electrical circuit, the clamped conductor can be easily removed from the latch;

- reliability and simplicity of design;

- body strength;

- clamp resistance to low and high temperatures;

- reliable fixation of the conductors in the clamp and the absence of the risk of spontaneous popping.

Also, wagons for connecting wires have small dimensions and ease of maintenance.

Device and technical parameters

Most wagons for connecting wires have a fairly simple device that includes the following components:

- Housing with openings for conductors located on one of the ends. This part of the clamp is made resistant to overheating and cracking in the frost of Polyamide 6.6. Depending on the number of connectors, the clamp can be double, triple, etc.

- The latch is a plate bent in a certain way from a spring chromium-nickel steel grade. The latch located inside the housing opposite each hole (connector) for conductors has a special window into which a conductive core cleared of insulation is inserted.

- Contact bus - a copper plate, with the help of which the conductors clamped in the clamps become part of a single electrical circuit.

In reusable models, the conductor is fixed in the clamp using small levers.

A variety of types and models of clamps for Wago wires allows you to use them to connect conductors in electrical circuits having the following characteristics:

- voltage - from 100V to 1kV (1000 V);

- current strength - from 6 to 323 A;

- current frequency 50-100 Hz.

A large assortment of these clamps allows the connection of conductors from various materials (copper, aluminum) with a cross section of 0.08 to 96 mm.kv.

The main types of Vago

The main role in connecting wires with Wago terminals is played by the internal spring clip.

Disposable wagons for connecting wires Push wire have a wedge-shaped “V” spring lock. They are used to connect copper and aluminum conductors with solid conductors. Currently, such clamps are rarely used, gradually giving way to more advanced and convenient analogues.

Reusable clamps Cage clamp differ from others in a characteristic spring clip in the form of the letter "p". Suitable for connecting conductors, both solid and multi-wire, containing a large number of small and thin cores.

Wagi Fit-clamp - The latest development of manufacturers of these types of clamps. They differ from other models by the presence of a special mortise contact, which allows not to remove insulation from the conductors inserted into it.

- Wago push wire

- Wago cage clamp

- Wago fit-clamp

Wagov Series Connectors

Among wagon wire connectors, the most common and popular models today are the 733, 222 series.

Clamps 733 They are a multi-pin system consisting of a plug with clamps for wires of the Cage Clamp type and a socket with soldered contacts. Models are protected against incorrect connection, code pins for marking various conductors.

Most often, such carriage clamps are used to butt-end stranded wires.

Reusable models 222 are clips with spring clips of the Cage Clamp type. Designed to connect copper and aluminum solid and multi-wire conductors with a cross section of 0.08 to 4 mm.kv.

The series includes models designed to connect 2,3,4,5 conductors.

For electricians and home masters, models of such series as 221, 223.773 are also in great demand.

How to use Wago

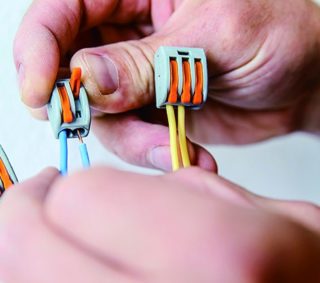

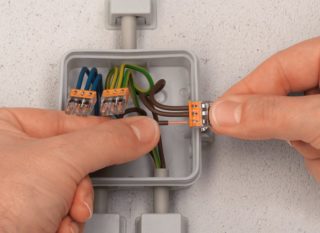

The process of connecting conductors using the most common 222 series terminal block consists of the following steps:

- 10-12 mm of insulation is removed from the ends of the connected conductors using a special tool.

- Without sudden movements, all the clamp levers go up.

- Each of the conductors is inserted into a separate clip hole.

- In turn, all the levers are lowered to their original position.

After joining with twitching of each conductor, the strength of the resulting compound is checked.

Before you pull out the wire from the Wago terminal, you must disconnect the section of the circuit where you plan to carry out electrical work.

Which is better to use, twist or wago

When wiring and connecting electricians, the car still competes with such a method of connecting conductors as twisting. To decide what is better to use - twisting or wagons, you need to consider the advantages of each of the connection methods.

The benefits of vago before twisting

The main advantages of such terminal blocks in comparison with twists:

- Fast installation - using electric wagons, they accelerate the process of wiring, connecting lighting devices. If you have a specialized tool for stripping insulation (stripper), the connection using the clamp of two conductors will take less than 5 seconds.

- Convenience - with the help of such a clamp, you can collect the necessary section of the electrical circuit, quickly connect the lighting device.

- Ease of use - each home master can connect wires with wagons without instructions.

- Safety - conductors connected in this way are reliably protected from oxidation and moisture.

- Possibility of disassembling - if necessary, the connection assembled using clamps is quickly and effortlessly disassembled.

Also, the connection assembled with the help of such clamps will take up little space and look more aesthetically pleasing than twisting wrapped with electrical tape. This advantage of the vagi over twisting is noticeable when using a power cable with a large cross section.

Advantages of Twisting Over a Wago Clamp

The few advantages of twisting over wagons - the cheapness of such a connection, resistance to extremely heavy loads - when the electrical characteristics are exceeded, the clamping contact of the wagon heats up more than twisting, which leads to burning of the insulation and the device body itself.

Also, the use of twisting is preferable to counterfeit clamps of dubious quality - in order to figure out how to remove the wire from the fake wago terminal block, you have to disassemble the terminal block.