A country house is clean air, greenery, convenience. However, owners encounter some difficulties, especially if the area is just starting to be populated and there is no central water supply and sewage system in it. In order not to feel discomfort and enjoy all the benefits of civilization, you will have to install a local septic tank, the main parts of which are pipes and storage capacity. If the pipes are installed in most cases of plastic, then the septic tank can be equipped with any material - concrete, brick, plastic, metal. They often use plastic, as it is cheaper, easier and easier to install. Moreover, it is not inferior in strength to other varieties.

Definition and purpose of containers for sewage

Containers for autonomous sewage serve as waste storage. They decompose organics and partially clean with aerobic and anaerobic bacteria. The reasons why you need to use sealed storage tanks for sewerage in the country:

Containers for autonomous sewage serve as waste storage. They decompose organics and partially clean with aerobic and anaerobic bacteria. The reasons why you need to use sealed storage tanks for sewerage in the country:

- Preservation of cleanliness of surrounding space and reservoirs.

- Close occurrence of groundwater. The closed bottom of the septic tank will not allow the sewage to rise and spill over the site.

- The ability to clean drains by 70% and safely drain them into the ground.

- Convenience of using sewage. In the house you can install any plumbing and washing appliances.

If a stream flows underground or there is a spring in the area, installing a sealed sewer in a plastic container will not spoil the quality of drinking water.

Plastic, fiberglass or metal tanks for sewage are used in the construction of all types of septic tanks - cesspool, multi-chamber well (septic tank), biological station.

The drive is a single-chamber tank, the drains from which are periodically pumped out with a sewer machine. Many people think that this is an expensive procedure that needs to be done often, so they install septic tanks.

A septic tank is a two- or three-chamber well. Between the partitions there are pipes through which the settled liquid is poured into the next tank for post-treatment. In a two-chamber tank, the second compartment has no bottom. The purified liquid goes into the soil or to the filtration fields. The help of a specialist is needed here, since not every type of soil absorbs water well and it can stagnate. The most successful option for installing a septic tank is sandstone, where the rate of absorption of water is high.

The biological treatment plant consists of several caissons for sewage, one of which has an air inlet. In such containers, water is purified by 95%, after which it can be removed to reservoirs or fields. The liquid is not dangerous for living organisms and humans. Industrial water is used for washing cars, watering the garden.

Production material

Capacities are made from polymers - plastic, fiberglass. On sale you can find metal and concrete specimens. Concrete is less and less used for arranging sewers. Due to constant humidity, it breaks down and serves much less. At the same time, installation work cannot be completed without the involvement of construction equipment due to the too high weight of the products. Concrete structures themselves are cheaper, but require additional work to seal and strengthen the connecting seams between the rings. The plus is that from the rings you can make a septic tank of any width and depth, cover it with a partition and put a concrete hatch. All these parts are manufactured by industry in appropriate sizes.

Metal cisterns or tanks are also heavy, so it’s hard to mount them yourself. For installation attract a construction crane. If the container is not painted with paint from the inside, then it will not last long due to corrosion. Before installation in the ground, the metal is coated on the outside with enamel so that the metal does not come into contact with the ground.

Plastic tanks and tanks

Plastic containers for sewage in a country house are in first place in popularity. Made of various types of polymeric materials:

- Fiberglass. The newest material, whose service life is 100 years. Compared with concrete and polyethylene, it remains leakproof during the entire period of operation. It is steady against aggressive liquids and does not deteriorate under the influence of detergents. Low thermal conductivity allows you to not heat the tank when installed in the ground. In terms of strength, fiberglass is comparable to steel, while it has a low weight and an affordable cost.

- Polyethylene. Temperature resistant material. If you choose polyethylene for sewage, you need to buy a seamless tank. For safety, it is built into a metal grate so that ground movements do not damage the tank. Plus polyethylene is mass production, which makes it possible to buy a tank in any supermarket at a cheap price.

- Polypropylene. At low density, polypropylene containers have greater strength, resistant to mechanical damage and temperature. A polypropylene canister can withstand heat up to 140 degrees without deforming or cracking.

To make the sewer system quick and long-term, it is recommended to choose polymeric materials.

Tank sizes

The dimensions of the septic tank are selected based on the time that the owners of the house or cottage plan to spend on the site. If the house has a bathroom, toilet, several sinks, as well as a washing machine and dishwasher, it is recommended that you install a tank of at least 10 cubic meters. This will allow the contents to be pumped out once every 2 to 3 years.

For cottages, where the owners are only in the summer, just 1 - 2 cubic meters. If you equip a storm sewer separately from the main one, water can be used to irrigate the site. In fiberglass, drains do not dry out during irregular use, therefore, it will be easy to clean. It is enough to pour a biological preparation based on bacteria into the container once a year so that they clean the drains.

About 150 liters of water per person are consumed per day. With permanent residence, a capacity of 3,000 liters will be filled in 20 days, unless a system for additional cleaning and release of liquid into the ground is provided.

Tank Recommendations

Metal structures are used mainly in industrial enterprises, as their size and weight cause installation difficulties.

Metal structures are used mainly in industrial enterprises, as their size and weight cause installation difficulties.

Concrete septic tanks are installed in summer cottages, where sewerage is used depending on the season, mainly in spring and summer. They do not require large expenses when buying, but over time, leakage may occur due to the destruction of concrete. If the soil in the area is unstable, it is able to move the rings, which will lead to leakage of sewage and pollution of groundwater. Concrete is chosen if it is necessary to meet a small budget.

The most common material is plastic, especially with quartz filler - fiberglass. The industry produces containers of various shapes and volumes, which are installed both underground and on the surface.

Consider the type of soil on the site. If sands prevail, then equip the filtration fields. In this case, the reservoir may be smaller. If the soil is clay, it is worth thinking about installing a biological treatment station so that the waste water does not fall into the soil.If groundwater comes close to the surface of the earth, drains can enter drinking water.

Installation and installation of capacity

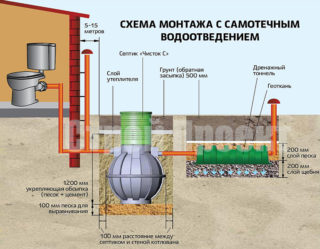

Before starting work, it is necessary to calculate the volume with a margin in case of installation of additional plumbing equipment or household appliances in the house. The place is chosen so that it is convenient to drive up and service the septic tank - sooner or later it will be necessary to pump out. At the same time, the container should be at the lowest point of the site, so that it is convenient to observe the necessary pipe slope for gravity drainage.

Before starting work, it is necessary to calculate the volume with a margin in case of installation of additional plumbing equipment or household appliances in the house. The place is chosen so that it is convenient to drive up and service the septic tank - sooner or later it will be necessary to pump out. At the same time, the container should be at the lowest point of the site, so that it is convenient to observe the necessary pipe slope for gravity drainage.

It is better if the pipes leading to the well are laid in a straight line. This will reduce the risk of blockages and the need for cleaning in an uncomfortable place.

It is not advisable to put the septic tank too close to the house. An unpressurized cap will let odors out. This problem can be solved by regularly adding biological preparations to the well to eliminate odors, but they do not work immediately, for 2 to 3 days.

Installation steps:

- Dig a hole. On the side there should be a margin of 50 cm for falling asleep sand after installing the tank.

- Lay the bottom with sand or concrete, so that the equipment does not move during operation and does not deform the pipes - this leads to a failure of the sewage system and an emergency repair.

- Set up the canister using the building level.

- Connect the sewer inlet pipe.

- Sprinkle sand on all sides of the container.

- Leaving the service opening on the surface, fill the canister with soil and compact.

If the well is large, you will have to order a crane so as not to damage the material and carefully place the canister in the pit.

The price of barrels for sewers for a private house depends on the material of manufacture. The most expensive are steel structures and fiberglass containers. The volume of the canister also plays a role. If a well is made using seamless technology, its cost will be higher than a product connected from several parts.