When repairing an old sewer system, sometimes it becomes necessary to connect pipes made of cast iron and plastic. If you make the docking incorrectly, the tightness will be broken. The pipeline will begin to leak, as the linear expansion rates of these materials vary.

Connection of a cast iron sewer pipe with a plastic

You can dock a cast-iron sewer pipe with a piece of plastic in various ways. It all depends on the state of the trunk and the connecting zone. Before starting work, you should collect tools and accessories, as well as dismantle old communications.

You can dock a cast-iron sewer pipe with a piece of plastic in various ways. It all depends on the state of the trunk and the connecting zone. Before starting work, you should collect tools and accessories, as well as dismantle old communications.

Preparatory stage

First of all, prepare the workplace and select the necessary tools and consumables. Some of them are necessary for any connection method, but some depend on the connection method. Think technology in advance.

To carry out the work you will need:

- plastic pipe of the required size;

- adjustable wrench;

- a grinder or hacksaw for metal;

- mallet.

Depending on which joining method is selected, a hand press, thread cutter or welding machine may be required. You should also choose the elements for the connection: fittings, adapters, rubber seals.

When drawing up a new wiring diagram, do not forget to add revision hatches to the project. They will facilitate the diagnosis of the system in the event of blockages and other problems. It should also be borne in mind that for a riser with a diameter of 110 mm, the best option would be to use pipes with a cross section of 50 mm.

Dismantling the old pipe

Joining places of old highways were sealed with tow and cement mortar. First you need to carefully remove all insulating materials, and then try to remove the pipe from the connection unit.

It is necessary to disconnect the pipes by scrolling, and in no case by rocking.

You can carefully use a mallet, but not a metal hammer, which can crack cast iron. If there is a risk of damage to the socket during undocking, you can carefully trim it with a cutting machine.

Having made an incision on a cast-iron pipe, do not try to break it off. The place of breaking will be uneven, and you will have to cut again. It is best to make a cut around the entire circumference of the pipe.

Methods for joining a plastic and cast iron pipe

Ways of joining a cast-iron and plastic trunk:

- flanged;

- fitting;

- with rubber gaskets;

- chasing tow or sanitary flax;

- silicone sealing.

The latter method is used if the condition of the cast-iron segment is good, and when a plastic product is inserted into it, a gap of less than 2 mm remains. They thoroughly clean and dry with a construction hairdryer the end of the cast-iron highway. The connecting part of the polymer pipe is wrapped with plumbing thread and installed in the socket to a depth of 8-10 mm. Slots are filled with silicone sealant.

Until the silicone has completely dried, no impact on the joint is allowed. Hardening takes about 5 hours, but it is better to start the system 24 hours after sealing.

Flange method

If the pipe section is large, it is better to use the flange method. Two discs with holes are used. The joint is formed by tightly pressing them to each other. When connecting a cast-iron branch with a smooth plastic pipe, adapters are used.When choosing a connecting element, carefully check that it is free of burrs or sharp edges, as they can ruin the polymer layer.

If the pipe section is large, it is better to use the flange method. Two discs with holes are used. The joint is formed by tightly pressing them to each other. When connecting a cast-iron branch with a smooth plastic pipe, adapters are used.When choosing a connecting element, carefully check that it is free of burrs or sharp edges, as they can ruin the polymer layer.

Nuances of installing a flange connection:

- strong joining can be achieved by using a straight shoulder with a conical transition;

- for highways with a cross section of more than 200 mm, take a free flange supported by a conical collar;

- for light pipes with a cross section up to 150 mm from any materials and heavy polymer products of the same diameter, free flanges are used with support on a free collar.

Before joining, cut the iron as evenly as possible in the area where the joint is planned. On the edge, put on a loose flange with a rubber gasket with a lap of no more than a centimeter. Then slide the flange piece onto the gasket and secure with bolts, tightening them evenly.

Fittings

The connection of cast-iron and plastic sewer pipes using crimp or cast fittings is used if the product cross-section is not more than 110 mm. A molded PVC fitting with a thread on one end and a socket for connecting a plastic pipe on the other is preferred if the end had to be cut off on cast iron.

To create a transition, clean the pig-iron product from dirt and paint and cut the thread into it by 30–50 mm. Re-clean dust and metal chips and shavings, wind several turns of FUM tape or flax. Screw on the fitting and insert the end of the pipe length into its cuff.

If a cast threadless product is used, first a sealing ring is installed in the socket, fixing it with special glue, and then a narrow fitting pipe is introduced into it.

You can also use crimp fittings, where there is a special ring for crimping with a slit. It allows you to avoid the quick failure of the connecting element and the appearance of leaks in the sewer pipes.

The use of rubber gaskets

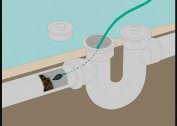

The transition from a cast-iron sewer to a plastic pipe by a similar method is carried out if, after eliminating the defective part of the old sewage system, there is an undamaged section with a straight socket. First, a rubber cuff is installed, and then a piece of plastic is inserted into the cast-iron pipe to a depth of 5–8 cm.

Sometimes it happens that in the remaining section of the cast-iron pipe there is no necessary socket. In this case, an adapter is used. You must act as follows:

- Cast iron is thoroughly cleaned of dirt and rust, then dried, and a layer of sealing compound is applied to the inside.

- The outer surface of the adapter is also coated with sealant and inserted into cast iron.

- The plastic end of the pipe end is inserted into the free end of the adapter.

At the end of the work, all joints must be additionally treated with a sealing compound.

Pressing technique

The method is chosen if it is impossible to connect the segments of the trunk in another way. The rules of caulking tow or linen:

The method is chosen if it is impossible to connect the segments of the trunk in another way. The rules of caulking tow or linen:

- In the place where the connection is supposed to be made, several layers of sealing material are wound on the end of the plastic pipe.

- The pipe is fully inserted into the cast-iron bell.

- With a wide negative screwdriver or a narrow spatula, the winding is tightly packed into the gap between the joined pipes.

- A mixture of cement, PVA glue and water is applied several times to the junction of cast iron with plastic.

After a day, the mixture sets, and you can begin to use the new pipeline. Such a connection of fan pipes has a time limit of up to 12 months. After this period, you will have to redo everything again or install a more reliable pipeline.

With the right choice of joining techniques and quality materials, the hybrid of old and new sewers will last for many years.