The installation of a sewer system is impossible without the use of fittings and other auxiliary elements. They allow you to change the configuration of the collector in a given direction. For private construction, polypropylene sewers with a rotation angle of 45 degrees or PVC elements are mainly used. They are easy to operate and due to the excellent smoothness of the inner walls, they ensure an optimal flow rate of sewage.

Definition and purpose of sewer

An outlet for a collector is a pipe element bent at a certain angle. The second name of the fitting is a corner, a knee. The main function of the product is to change the direction of the sewer flow towards the central riser or septic tank from the entrance from the wall of the house and in other parts of it. As a rule, the branch has the same cross-section as the sewer pipe.

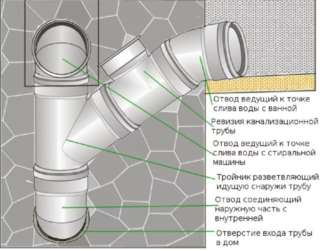

As additional fittings for the sewage system, plugs and tees are used. The first helps to limit the movement of the flow of water. The second allows you to branch the collector if the system is laid for two or three buildings at the same time or storm and fecal-domestic sewage from two different systems will flow into a common receiver.

Production material

The market presents shaped products from such materials:

- Steel. In everyday life, when installing a sewage system, it is used extremely rarely. This is due to the tendency of the metal to corrosion and the complexity of installation work. For the device of the steel channel, welding must be used. During the operation, a thin coating layer of steel pipes is broken, which leads to faster wear. To extend the life of the steel manifold, galvanized metal is used.

- Cast iron. Durable material with impressive weight. To work with cast iron is also inconvenient, as well as with steel. Installation of the pipeline is carried out using electric welding equipment, soldering or other labor-intensive methods. Shaped cast-iron elements are not equipped with gaskets. Metal is prone to corrosion, especially when installing the outer part of the sewer. On the inner walls of the cast-iron branch, a silt outgrowth quickly forms.

- Ceramics. Such a drainage channel has a long service life, a high flow rate due to smooth internal walls and ease of installation. However, the cost, as well as the weight of the ceramic tap, are high for a private master.

- Low pressure polyethylene (HDPE). Shaped elements are black and are used only with external sewage. In private construction, PND is not used. Its main purpose is the construction of industrial and central city highways. Installation of polyethylene tubes is carried out by soldering or using special couplings. Low-pressure polyethylene is inert to aggressive inclusions and does not respond to temperature changes.

- Polyvinyl chloride (PVC). Optimal tap material for private construction. The installation of all the elements of the sewage from PVC takes place in a socket. This greatly facilitates the construction process. For internal work, bends of gray color are used, for external - brown. PVC is not afraid of aggressive environments and has low thermal conductivity. The outer part of the sewage system will freeze in the soil with a lesser degree of probability than a cast-iron or steel network.

- Polypropylene. Bends from this material are suitable for installation inside the building, since the PP is afraid of ultraviolet radiation. Shaped elements are equipped with sockets for simplified installation.Through polypropylene pipes, it is possible to let fluid up to 95 degrees. The material is not afraid of this.

- Steel

- Ceramics

- Cast iron

There are no bends for asbestos-cement pipes, therefore, metal sewer semi-bends are used in such a pipeline.

When installing the collector, it is important to use all the elements from the same material. If necessary, combine several diverse parts using special adapters. More often these are bends for corrugated pipes.

Without exception, all shaped elements are produced strictly according to GOST. Otherwise, the installation and further operation of the system will cause difficulties.

Types of bends

In addition to the classification of bends according to the material of manufacture, they are divided into types according to the degree of the angle of bending. You can purchase drainage elements of 15, 30, 45, 67 and 87 degrees. At the same time, bends can be joined together with any bend, but it is not recommended to make too sharp turns of the collector. In such areas, blockages often occur.

In addition to the bending angle, the bends are divided into single-bell and double-bell.

Both types change the direction of the liquid (air, gas) in the system, but vary in the complexity of installation. A single bell-shaped branch has, as a rule, a smaller bending angle.

Parameters, dimensions, weight

For the device of the sewer collector, you can purchase branches of any diameter. The table shows the common parameters of shaped elements.

| Diameter (mm) | Length (mm) | Weight (kg) depending on the material of manufacture |

| 15 | 28 | 0,04 |

| 20 | 29 | 0,06 |

| 25 | 38 | 0,11 |

| 32 | 48 | 0,19 |

| 40 | 57-60 | 0,26-0,5 |

| 50 | 75 | 0,5-1 |

| 65 | 100 | 1-1,7 |

| 80 | 120 | 1,4-2,8 |

| 100 | 150 | 2,2-5 |

| 125 | 190 | 3,8-6,2 |

| 150 | 225 | 6,1-13,3 |

| 200 | 300 | 14,9-39 |

| 250 | 375 | 23-46,7 |

Selection recommendations

A shaped element for sewerage is selected according to the following criteria:

- The material of manufacture. It is desirable that it fully coincides with the type of pipes used for laying the collector.

- Internal section of products. It must correspond to the diameter of the pipes: if the collector has a cross section of 110 mm, the outlet for sewer pipes is taken with a diameter of 110 mm, no more and no less.

- The presence of rubber seals. They seriously facilitate the installation of sewage.

- Compliance with GOST products. As a rule, the outside of the product is marked accordingly.

- Bending angle. It is important to correctly calculate the line configuration in order to prevent errors when setting its direction.

- The presence of a smooth smooth inner surface of the product. Otherwise, in the future, wastewater with large inclusions will provoke the formation of growths on the walls of the collector.

As a rule, when installing household sewers in a private house or apartment, plastic shaped elements are used.

Installation Rules

The installation technique of the tap consists of several stages.

- Cut the pipe in the place where the branch will be attached to it. It is important to ensure that the retraction is made strictly perpendicular to the central axis. Otherwise, the segment of the tube will not enter the socket of the outlet tightly and all the way around the entire circumference.

- The cut edge on the inside and outside of the pipe is erased by erasing the burrs. This is important because if they are present, clogs will form in the pipe from fibrous deposits, which can cling to irregularities. Then, a small chamfer with an angle of 15 degrees is made along the outer edge.

- A groove with the same angle is also formed on the outer edge of the outlet to subsequently insert the edge of the element into the next pipe.

The edges of the parts of the collector are treated with sealant and joined together in the direction of the pipeline. When connecting the socket, a small compensation gap of 10 mm must be left. Deepening parts of the collector beyond this mark is not recommended.

Joint Sealing

During the installation of bends, it is necessary to monitor the quality sealing of all joints, otherwise the collector will leak. In most cases, all plastic elements are already equipped with rubber seals. They are inside the bell. If they are not, the rubber ring is inserted until it stops before the knee is joined to the tube.

Strengthen the sealing effect helps special plumbing sealants. They are pre-applied to the rubber seal over the entire circumference. When choosing a sealant, it is better to give preference to neutral than acid. The former are more reliable, although they are more expensive. Acidic compounds are not allowed to be used when mounting cast-iron or steel manifolds. Otherwise, the acid will corrode the metal.