Check whether all the parameters of the air conditioner are met, you can visually. The correct operation of the external and internal units is primarily evaluated according to installation standards.

How to check the quality of installation of the air conditioner

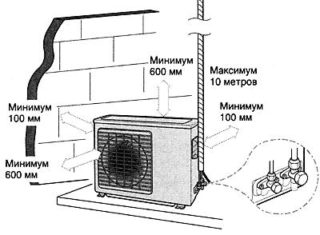

Before checking the operation of the air conditioner, you must make sure that the outdoor unit is correctly installed. During operation, it vibrates all the time, so the wall for fastening is chosen strong and even. The block is mounted by level. 10 cm should be left between the module itself and the wall, otherwise the unit may overheat in the hot season. Brackets are mounted on anchor bolts.

A visor is installed from above, protecting from rain and ice.

The drainage pipe should be inclined so that condensation does not accumulate and does not pour into the apartment. If you plan to turn the equipment on in cold weather, the drainage must be heated so that ice plugs do not form.

External equipment is mounted relative to internal at a distance of no more than 3 meters. Each model has its own recommendations, so the wizard checks the instructions. There should be free access to the outdoor unit to clean it if necessary after the season of operation.

An important step in checking the installation of an air conditioner is to fix the copper lines. It is strictly forbidden to cut the tubes with a hacksaw. Small chips can cause compressor damage, therefore only special tools are used. The tubes are fastened with a roller, otherwise their performance is not guaranteed.

The front panel of the indoor unit should be open. Furniture or walls can be located at a distance of 2.5 meters, so as not to interfere with the movement of air masses.

Checking the air conditioner for leaks

At the end of the installation, the system is evacuated. Air and moisture are pumped out of the tubes, which will not come out on its own, then freon is pumped. If this stage is neglected, malfunctions and even breakdown of the compressor, the most expensive component, can occur. Some masters offer air bleeding and purging the system with freon. This method works on a number of models, but not all. Evacuation is the best method to remove residual moisture and air from the tracks.

It is better to check and clarify the actions of the installation team during the execution of work, because if it breaks, it will be more difficult to prove the mistakes of the masters.

Before checking the operation of the air conditioner and the first start-up, it is necessary to determine the height difference between the blocks. Look for manufacturer recommendations in the annotations upon purchase.

How to check the air conditioner before the season

Before the summer season, after 6 - 7 months of a break, the air conditioner is checked. You need to do this in the following order:

- open the front panel and inspect the filter - if it was not cleaned before winter, it is removed, washed, then dried;

- assess the condition of internal parts; vacuuming may be necessary;

- close the windows and doors in the air-conditioned room and turn on the minimum temperature;

- after 10 minutes, check with a thermometer how much the room has cooled. The difference between outdoor temperature and room temperature should be at least 8 degrees.

The operation of the compressor is checked by placing a hand on an external device - it vibrates slightly. A weak air flow indicates the running fan of the indoor unit. If the air blows cold, then the air conditioner reaches its operating capacity.

The operation of the compressor is checked by placing a hand on an external device - it vibrates slightly. A weak air flow indicates the running fan of the indoor unit. If the air blows cold, then the air conditioner reaches its operating capacity.

If the parameters are normal, the cooling works - you can start using the device daily.

It happens that after the winter the device does not work fully. First, the problem is sought in the internal equipment, then they are transferred to the external. To test the air conditioner with your own hands, you need tools, knowledge of the principles of operation of climate technology and skills to work with split systems. In the absence of one of the conditions, it is better to call a master who will determine the cause of the weakening power and eliminate the breakdown.

Purchase Check

It is advisable to buy HVAC equipment from a trusted company that has been operating in the market for these services for at least three years. The absence of a service center is a big minus, because in case of breakdown you will have to look for craftsmen, and they are busy servicing their customers in the season.

Before buying, you should decide what functions the device should have in addition to cooling.

Store employees should take an interest in the area of the premises, the availability of household appliances that produce heat, the number of people, and the time of building the house.

Check if the device is working or not, the store will not work. All possible nuances should be clarified before installation.

Checking the performance of a used air conditioner

Older models are sold in good condition if maintained regularly. But it so happens that a defective model was purchased that works below the declared capacity or with failures that the masters could not eliminate.

To find out if the air conditioner is working, connect both units to each other. It is not necessary to hang them on the wall - just connect the copper pipes of the two units and connect the electrical wires. Evaluate the operation of the device by the noise, the cooling time of the room, the work of all functions. The verification procedure is best entrusted to a master who is versed in climate technology, and will give his opinion.

To find out if the air conditioner is working, connect both units to each other. It is not necessary to hang them on the wall - just connect the copper pipes of the two units and connect the electrical wires. Evaluate the operation of the device by the noise, the cooling time of the room, the work of all functions. The verification procedure is best entrusted to a master who is versed in climate technology, and will give his opinion.

Check the air conditioner upon purchase by the following parameters:

- electricity consumption;

- system pressure (gauge manifold);

- Compressor temperature

- current.

Tools for verification are available in the arsenal of a specialist. If you save on purchase, it is advisable not to save on verification.