Air conditioning systems or abbreviated SLE are designed to create comfortable thermal conditions for a person or equipment in the room. They allow you to create a favorable microclimate both in the heat and in the cold by using in its composition a refrigeration machine running on freon.

Comfortable conditioning includes essential air conditioning: cooling, heating, drainage, humidification, filtration, ionization, etc. Maintaining the given parameters is almost independent of the parameters of atmospheric air and their oscillations. The only exceptions are the cases of using hard currency at unacceptable temperature values on the street, which were determined by the equipment manufacturer.

If we consider in more detail the purpose of air conditioning systems, we can divide them into two groups:

- SLE comfortable - maintain the basic parameters of the air (temperature, humidity, cleanliness) that meet sanitary and hygienic standards;

- SLE technological - maintain the required air parameters in a particular production or technical room.

For example, one of the tasks of an air conditioning system for an apartment is to ensure a normal level of humidity. The same 20% is the lower limit of the norm, upon reaching which the human skin and its mucous membranes dry, and 70% is the upper limit, at which the heat exchange of the body with the environment is significantly reduced, the cardiovascular system is worsened, headaches begin and felt lack of oxygen. The air conditioner maintains average humidity in both summer and winter - about 40-60%.

SLE technological create comfortable conditions for equipment in production. For example, the reliability of high-power computers will be ensured by precision systems capable of controlling temperature, humidity and air mobility with an accuracy of 0.5%.

Not everyone knows that the purpose of an air conditioning system is also maintaining an acceptable level of carbon dioxide in a room.

In children's hospitals, offices, shops and apartments, the indicators differ markedly, so completely different types of air conditioning systems are installed in these institutions.

Normal gas composition of the air can provide air conditioners that are able to carry out a regular flow of oxygen into the room, that is, increase the rate of air exchange. Excess or lack of carbon dioxide in the body adversely affects health.

In general, the classification of hard currency is very diverse. They can be divided according to different signs:

- according to the principle of placement relative to the served area - local and central;

- according to the principle of action - recirculating, direct-flow and combined;

- by the number of serviced premises - single and multi-zone;

- by the number of regulators of the parameters of the outgoing air - single-pipe and two-pipe.

This is not an entire list of classifications. Many authors of thematic books hold different points of view on this issue and put forward their versions of dividing hard currency into classes.

Types and arrangement of air conditioners

If we talk about the types of air conditioning systems, then there is a wide variety, as there are devices for the apartment, and devices for office buildings, and units for industrial premises. Automation of air conditioning systems in this case is achieved using additional equipment.

They can be made in the form of a monoblock or a two-component device - a split system.The first have in one case all the elements that ensure the movement of freon along the refrigeration circuit. The second has more noisy parts placed in an outdoor unit located on the street, and filters, a fan, an evaporative radiator, sometimes a control board and other quiet parts remain in the indoor unit (room).

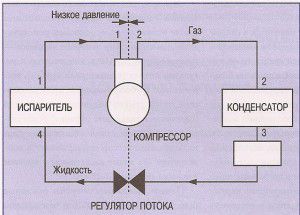

The device of any hard currency operating on freon implies the presence of such important elements as:

- a compressor that compresses and draws in refrigerant;

- heat exchangers of evaporative and condenser type, through which heat energy is transferred from freon to the environment;

- fans for blowing heat exchangers;

- mechanical filters + often fine filters;

- control board responsible for the operation of all electronics;

- flow regulator (expansion valve or capillary tube) for dosed supply of liquid refrigerant from the condenser to the evaporator;

- 4-way valve for “warm” air conditioners, redirecting refrigerant to the other side.

The construction of an air-conditioning system of an industrial type is much more complicated. In the same chiller, there can be several rows of fans or a certain number of three-way valves that change the direction of water flow in a water-cooled chiller.

The simplest circuit diagram of an air conditioning system is shown here. It reflects all the main components of the compression cooling cycle along with connecting communications.

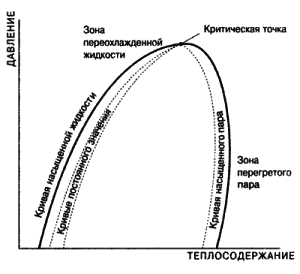

In almost all hard currency, the circuit concept is identical. You can imagine the cooling cycle in the form of a graphic image, as in the figure. Here, the left side of the curve is the state of saturated liquid, and the right is the state of saturated vapor. At the junction point, freon can be in any state.

Domestic hard currency air conditioners

As already mentioned, there are air conditioning systems for residential premises - these are household split-systems, and industrial - to meet the needs of production or other industrial and technological facilities. There are so-called semi-industrial or commercial systems that are installed in offices, shops, administrative buildings and other public facilities.

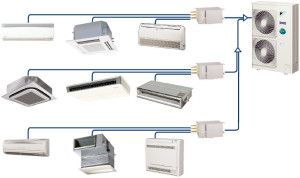

Air conditioning systems for an apartment include wall, floor-ceiling, cassette, channel and column split systems, as well as window and mobile monoblocks, which differ in the design of the indoor unit. They are often used as semi-industrial devices, but only with an increased power range. The most popular household cooling device is wall split, but its power potential is limited, as users of household appliances do not need a strong stream of chilled air.

In split systems, the compressor is located in an external unit, so the operation of such devices is completely silent. If there are several indoor units connected to external electric wires and the freon route, then we are already talking about a multi-split air conditioning system. An outdoor module can be connected from 2 to 9 indoor.

VRV and VRF air conditioning systems

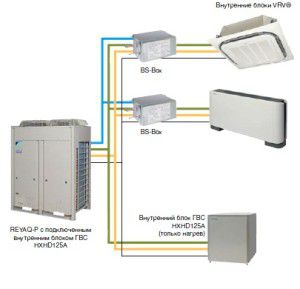

There are multi-zone systems that work with only one type of indoor unit - for example, wall-mounted, that is, all internal modules must be exclusively of the same type. But modern manufacturers produce multi-split air conditioning systems with the ability to connect different types of indoor units to one outdoor, while for buildings with a large number of rooms with different heat loads, multi-zone systems with variable refrigerant consumption have been created for several years. They have one external unit capable of providing dozens of internal ones.

For example, the MITSUBISHI ELECTRIC CITY MULTI series is designed for 16 indoor modules of various types and completely different capacities. These inverter systems with variable performance are equipped with a special thermostatic valve, which changes the power of the unit depending on the load and thereby regulate the consumption of freon. The temperature is maintained due to this more accurately and no differences occur.

The multi-split type indoor units of the air conditioning system, like the MITSUBISHI ELECTRIC, can work in different modes at the same time. This provides a BC-controller that distributes the freon between the blocks and separates it with a separator into steam and high-pressure liquid. Thanks to this separator, the device of this air conditioning system is simplified - the blocks are connected to the controller with just two pipes. Installation becomes cheaper and easier, the number of fittings for docking is reduced, the permissible length of the pipeline and elevation increases significantly.

As a rule, in simple multi-split systems, the outdoor and indoor units are connected linearly, that is, each room module needs a separate track. In multi-zone ones, only one pair of tubes departs from the external unit, which then branches out according to the tree-like principle with the help of refnets.

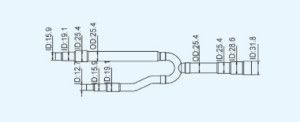

Refnet has different section sizes. When combined with the pipe, it is cut along a line of a suitable diameter.

Multizone devices with variable refrigerant flow rate have another name - VRV-conditioning or VRF. Their advantages are obvious:

- the length of a single pipeline system reaches up to 100 m and even more, elevation differences between blocks - up to 50 m, which allows you to place the outdoor module in any convenient place;

- the number of indoor units connected to one external unit reaches several tens, while the performance of the latter can be 30% less than the total performance of the former;

- control can be carried out both from individual remote controls, and from a central stationary console or computer - special software makes it possible to combine a computer network with an air conditioning network and control each air conditioner from a personal computer in different areas of the building.

There is practically no difference between the concepts of VRF-conditioning and VRV. Initially, the creation of such a system belongs to DAIKIN, so other manufacturers use a different abbreviation, which does not change the meaning. It’s just that different manufacturers endow the manufactured equipment with different technical capabilities (track length, recuperation ability, etc.)

It is worth remembering that the operation of all units in different modes (cooling and heat) is possible only with a three-pipe connection system. Two-pipe VRF-conditioning system is able to provide different preset air parameters, but only in one mode.

The outdoor unit of some VRV air conditioning systems may look like a semi-industrial dual-fan unit or have a more serious structure, as in the picture.

The disadvantage of air conditioning using the VRV-system can be considered noticeable noise emitted by the flow valve. They try to hide him in the utility room or false ceiling. There are also devices with an external valve.

Design and calculation of air conditioning systems

When choosing the right refrigeration device for an apartment, they often use the express method of calculating SLE, which takes into account the approximate thermal load on the room, and the closest type size of the device is selected with respect to it. The selection is made at nominal cooling capacity.

For 10 m², take 1 kW of power in the cold and add to the received data from 10 to 30% in the form of a reserve for incoming heat from household appliances, window and door openings, lighting fixtures, etc.

This methodology for calculating a suitable air conditioning system can simplify design work, but allows for inaccuracies if applied to systems with great capabilities and a more complex device, for example, to multi-zone hard currency. It is quite applicable when buying household split systems and window / mobile monoblocks.

What you need to know and consider when designing air conditioning systems with a complicated device? First of all, they look at the source data:

- regional location of the object and location relative to cardinal points;

- construction drawings and floor plans;

- category of the object, taking into account fire safety standards;

- drawings showing the location of all the equipment of the building;

- number of lighting devices;

- energy characteristics;

- data from existing hard currency.

After analyzing all the data provided, they proceed directly to the design of hard currency, which usually takes place in two stages.

At the first stage, they choose a system with technical justification why this particular type is better for this room. Here the air conditioning system is calculated by power, its location at the facility is determined, the number of devices involved is prescribed, the area for installation is determined and the approximate cost of all work with the equipment is calculated.

The second stage involves the development of a working draft taking into account the building layout, thermal characteristics of building structures and the technological task. Be sure to calculate the air exchange, heat and humidity balance of the room, conduct aerodynamic calculation of air networks and hydraulic calculation of fluid communications.

Further, everything is agreed with the customer, SES, fire inspection and, if necessary, changes are made to the project. After the equipment is ordered, the working drawings are handed over to the installers.

Maintenance and repair of air conditioners

Any hard currency requires regular maintenance, that is, cleaning and checking operating parameters, and in some cases, repair.

Standard maintenance of hard currency is the prevention of equipment breakdowns. It consists of:

- external cleaning of blocks;

- washing and disinfection of filters, fans, radiators;

- cleaning the drainage pipeline;

- checking the pressure in the system and the temperature of the outgoing air flows;

- broaches fasteners.

If necessary, refueling or a complete refill of the circuit with freon may be necessary.

Typically, the main purpose of cleaning the air conditioning system is to prevent the failure of parts such as a fan, four-way valve, compressor. If it is not carried out, then the efficiency of the device decreases, bacteria begin to multiply inside, when the device is turned on, an unpleasant odor appears, and the listed elements break down.

Even if the air conditioning system was cleaned regularly, sometimes breakdowns are unavoidable. Voltage drops lead to the failure of the control board, which is the "brain" of the machine, and violation of the manufacturer's recommendations for its use in certain temperature limits leads to problems with the mechanical elements of the circuit.

An example of what air conditioning repair might be required is shown in the table.

| Problem | Cause | Recovery work |

| Jamming of the compressor; uneven start; inability to start | Switching on the device for heating in winter at temperatures below -5 ° C

Factory marriage Poor installation of the track |

Restoring the performance of a part or its complete replacement |

| Jamming of the fan in the external unit; fan blade breakdown | Heavy pollution due to lack of maintenance

Turning the appliance on in severe frosts Factory marriage |

Fan replacement |

| LED flashing; care in error codes; incorrect operation of the main modes; malfunctions of the fan, compressor, starting capacitor | Burnout of individual chips

Full burnout of the board Factory marriage |

Single chip recovery or full board replacement |

| Freezing blocks; poor cooling; noise at work | Freon leak | Refueling / full filling with freon, replacement of milling joints, pipe re-soldering |

Maintenance of industrial hard currency and repair and restoration work on troubleshooting them are more complex and take more time. Timely identification of problems and their elimination helps to avoid stopping the entire working process at the production site or any other large non-residential object.

Preventive maintenance of household systems is recommended twice a year. Industrial plants need to be inspected and cleaned much more often - at least once a quarter, maximum - once a month. It all depends on the operating conditions and the location of the hard currency.