Freon R134A is a representative of modern freons used in climate and refrigeration equipment. It began to be used in connection with the introduction of restrictions on the operation of various systems with chladones containing chlorine. Freon R134A is used both in pure form and as part of mixtures. It has undeniable advantages in comparison with the R12, but it has certain features that affect operation.

Description and application of freon R134A

All freons are substances boiling at low pressure, and precipitating in condensate at high. These properties allow the successful use of refrigerants in the creation of HVAC and refrigeration equipment.

There are various types of freons:

- chlorofluorocarbons;

- fluorocarbons;

- chlorofluorocarbons;

- bromofluorocarbons;

- fluorocarbons.

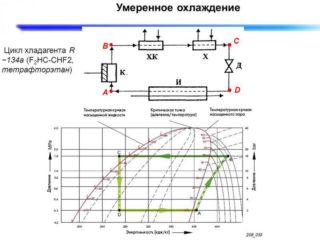

The latter includes R134A freon, a refrigerant made without the use of chlorine. Colorless gas has a chemical name - tetrafluoroethane.

Most often, refrigerants are charged with air conditioners in automobiles, industrial refrigeration units and domestic climatic equipment. It is used in the process of creating other brands of freon. The refrigerant is designed to operate in the medium temperature range.

Freon R134A can be used in systems where other refrigerants are officially used. This is possible due to the inclusion of the substance in most chladones.

Freon is used in pneumatic weapons, refuel in cylinders for dust cleaning devices, and is used to cool water on an industrial scale. In the liquid state, the substance is widely used to cool personal computers (systems for overclocking).

Freon has a Russian counterpart, called R-600A. Despite the similar properties of Freon R134A and R12, they can not be mixed. Such actions may cause equipment malfunction. Domestic manufacturers claim that their product was created taking into account the operation of Russian compressors.

Advantages and disadvantages

Freon is non-flammable and non-toxic. The saturated vapor pressure of R134A is higher than that of R12. This means that the refrigeration heat exchanger will take longer to heat up.

Freon is non-flammable and non-toxic. The saturated vapor pressure of R134A is higher than that of R12. This means that the refrigeration heat exchanger will take longer to heat up.

The main advantages of freon:

- Reliability of use in any conditions. When working with the substance there is no need to additionally create exceptional safety conditions.

- Consistent performance.

- High thermodynamic performance.

- Zero ozone depletion potential.

According to test results over a wide temperature range, it was found that R134A refrigerant has a greater degree of performance than predicted. The substance has the best heat transfer performance compared to R12 and R22.

One of the significant drawbacks of freon is decomposition with the release of harmful fumes when heated above 250 degrees. In addition, it has a high coefficient of the greenhouse effect, which is 1300 times higher than that of carbon dioxide.

Another disadvantage of Freon R134A is its high hygroscopicity. When the hose permeability increases with improper maintenance, the risk of moisture entering the system increases. If air enters and further compresses, a combustible mixture may form.

Refrigerant Features

R134A gas is best used in medium- and high-temperature refrigeration units. Compared to peers, it copes better with annual temperature increases, which allows it to be used in special sealed cooling systems.

Freon is used when upgrading equipment operating at low temperatures.

Other features of colorless gas:

Other features of colorless gas:

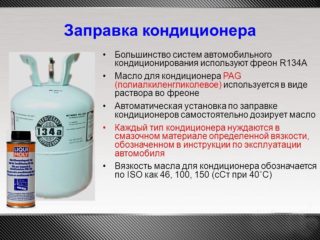

- Refrigerant must not be mixed with traditional synthetic and mineral oils. Freon R134A does not dissolve in them. Oil is not transported along the cooling circuit, settling in heat exchangers and interfering with heat transfer. Polyalkylene glycol oils have been developed specifically for the new refrigerant. They have high hygroscopicity and low dielectric conductivity.

- When upgrading equipment, it is necessary to replace the compressor, otherwise the refrigeration unit will have reduced cooling capacity.

- The use of refrigerant in water cooling systems with centrifugal and screw type compressors has prospects.

- It is easier to charge the refrigerant after a leak, in comparison with popular counterparts.

- The R134A molecule is smaller in comparison with R12, therefore, increased demands are made on the tightness of the system, and especially on the joints.

R134A freon can be used on medium temperature equipment in Russia where R12 is prohibited. However, the latter can not be replaced in everything. Some units can operate at a boiling point of -15 degrees and above. In these situations, the R134A refrigerant has a lower refrigerating capacity: 6% lower than R12. In these cases, a compressor having an increased hourly volume is used.

Thus, to use R134A, you need:

- hygroscopic oils;

- suitable compressors;

- modernized units of refrigeration equipment.

When testing techniques with essential oils, conventional metal elements were used. When using flexible hoses, elastomers are selected separately. This condition provides minimal permeability of the walls and the least amount of residual moisture.

All systems are thoroughly dehydrated before refueling and changing the oil. Drying filters are installed in the refrigeration circuit, which must correspond to the characteristics of R134A molecules.

With a competent approach to the use of the refrigerant, there are no problems when working with it.

Freon R134A: characteristics

The table shows the technical data of the substance, which will help to compare the refrigerant with the analogues available on the market.

| Name of indicator | Numerical value, measure |

| Boiling temperature | -26.5 degrees |

| Critical pressure | 4.06 MPa |

| Critical temperature | 101.5 degrees |

| Ozone Depletion Potential | 0 ODP |

| Molecular weight | 102.03 g / mol |

| Fluid density | 126 kg / m3 |

| Gas density | 5.28 kg m3 |

| Solubility in water | 0.21 rpm |

Thanks to these indicators, R134A freon is used in the automotive industry, industry, when creating household refrigeration equipment.

The composition of Freon R134A includes:

- Freon 134 - 62.9%;

- Freon 218 - 32.6%;

- H-butane - 4.5%.

Tests for storage of the substance revealed a high hydrolysis resistance on aluminum, copper, brass and stainless steel.