The smallest metal particles and moisture cause serious damage to the compressor mechanism. During the installation of the system, copper chips and dust get inside the pipes. The working circuit passes the vacuumization process, but it is not always possible to completely remove contamination. Drops of water may remain on the walls of the line or get inside with hygroscopic synthetic oil. To protect an expensive unit from breakage allows the filter dehumidifier of the air conditioner (FOK). When developing a resource or a node malfunction, its replacement is required.

What is an air conditioner filter drier

The filter drier is an element of the operating circuit of the climate and refrigeration equipment. Its task is to remove liquid and acid from the refrigerant and prevent clogging of the capillary tube. The danger of the presence of water in the circulating freon is underestimated. It changes the properties of the oil used in the installation. The product decomposes to form acids. When the liquid freezes, the capillary tube is blocked, the suction pressure rises. The compressor overheats in an intensive mode of operation. The metal parts of the installation are corroded.

The filter drier is an element of the operating circuit of the climate and refrigeration equipment. Its task is to remove liquid and acid from the refrigerant and prevent clogging of the capillary tube. The danger of the presence of water in the circulating freon is underestimated. It changes the properties of the oil used in the installation. The product decomposes to form acids. When the liquid freezes, the capillary tube is blocked, the suction pressure rises. The compressor overheats in an intensive mode of operation. The metal parts of the installation are corroded.

Moisture enters the air conditioner circuit in various ways:

- during installation of the climate system;

- leakage on the suction side;

- opening the circuit for maintenance;

- The oil or refrigerant used during charging contained moisture.

Any deviations from the operating mode lead to breakdown or complete wear of the compressor. Installation of the FOC unit protects expensive equipment from interruptions in operation and wear of spare parts.

Operating principle

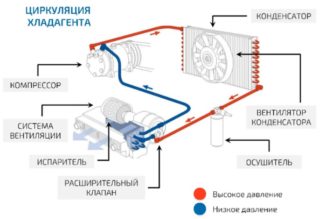

The assembly location is between the condenser and the capillary tube. When the climate technology is turned on, the compressor starts to work. The unit pressurizes the gas compressing pressure. Condensed refrigerant enters the filter drier in the liquid phase. The hydraulic resistance of the adsorbent is small, so Freon passes the knot unhindered. The principle of operation of the dehumidifier of the air conditioner is the absorption of moisture from the refrigerant by the hygroscopic zeolite. Solid porous material absorbs water molecules, and larger particles of freon pass it freely. All models of split systems are equipped with filters with dehumidifiers working according to one scheme.

The type of desiccant is selected by the type of freon and oil. For a system with a mineral product, the addition of active alumina is relevant. Polyester oils require an adsorbent that retains moisture well. Existing dirt particles are also retained by the filter. At the exit, a fine-mesh mesh prevents the flow of zeolite granules with the flow. FOK is located on the highway section in front of the thermostatic valve. When mounting, the arrow on the housing must match the direction of flow. The filter is a universal device, it cleans and dries the freon.

Node device

The part is a metal cylinder 80-170 mm long, 16-30 mm in diameter. The dimensions of the unit depend on the model of the air conditioner into which it is inserted. The housing is hermetically sealed by plasma welding to prevent refrigerant leakage. The surface is treated with an anti-corrosion compound. There are two copper nozzles for refrigerant inlet and outlet. Inside the case, metal or polyester nets are installed. Between them is a core filled with granules of synthetic zeolite.

The part is a metal cylinder 80-170 mm long, 16-30 mm in diameter. The dimensions of the unit depend on the model of the air conditioner into which it is inserted. The housing is hermetically sealed by plasma welding to prevent refrigerant leakage. The surface is treated with an anti-corrosion compound. There are two copper nozzles for refrigerant inlet and outlet. Inside the case, metal or polyester nets are installed. Between them is a core filled with granules of synthetic zeolite.

In some models, an additional nozzle is installed at the inlet. It is used when evacuating the system. One side of the core rests on a perforated plate and anti-vibration insert.The back part is fixed by a spring. A mesh is installed at the input to prevent zeolite granules from entering the capacitor. The diameter of the adsorbent particles is 1.5-3 mm. At the exit there is a grid with smaller cells. Its purpose is to trap solids from freon.

Varieties of design FOK

As a dehumidifier, substances with varying degrees of moisture absorption are used. With the same housing parameters, the difference in the volume of retained liquid reaches 30 g. There are several types of FOC:

- for installation on a liquid line;

- bidirectional or Bi-flow filter - installed in any direction, has built-in check valves;

- combined options with a receiver;

- filter for suction area, removing acid.

The bidirectional version is designed for air conditioners operating in cooling and heating mode. In such models, check valves allow freon to move from the outer edge to the center. Moisture and dirt particles are trapped in the filter regardless of flow direction.

Inside the case of some models, peculiar fuses are installed. This is a melt insert, triggered by heating to 85-100 ° C. The part melts and releases the refrigerant.

Step-by-step replacement instructions

Installing a moisture indicator with a sight glass helps to monitor the condition of the dehumidifier filter for the air conditioning compressor. The color of the device determines the moisture content in the refrigerant. Green bars indicate normal. Staining in yellow and the appearance of bubbles in the viewing window indicates clogging and a decrease in the efficiency of the node. This is one of the reasons for replacing the filter drier. The detail changes in other cases:

- loss of tightness at the soldering point of the housing;

- compressor replacement;

- opening the cooling system.

When developing a resource, the node is not restored, but cut out and replaced with a new part. The service life is indicated in the documents of the air conditioner. Manufacturers recommend replacing the spare part for any impact on the system. The cost of the dehumidifier is low, it is worth taking the advice of specialists.

To perform the work, special tools will be required:

- pipe cutter;

- burner;

- Vacuum pump;

- gauge station;

- filling cylinder.

Freon is used as a consumable; the type of gas is indicated on the nameplate of the air conditioner and in the documents.

- Solder off the worn part with a torch or cut with a pipe cutter.

- Strip pipe ends to install a new dehumidifier filter.

- Solder a new knot. Used welding, flux and solder. In the process, a protective gas is used that removes heat from the soldering point. Nitrogen is usually taken, it prevents overheating and destruction of the polyester mesh of the filter. The housing (arrow) is positioned in the direction of flow of the refrigerant. If the model is bidirectional, it is set arbitrarily.

- The system is evacuated, the pump is connected via a manometer station. Operating time depends on the pressure gauge. The procedure removes air, pollution and moisture from the climate equipment.

- Refrigerant is poured into the working circuit.

- Checks system sealing.

- Test run of equipment is being carried out.

Replacing the filter drier of the air conditioner is associated with depressurization of the split system line. Assembly of the unit requires expensive equipment and special skills. It is better to entrust it to professionals from the service center. Errors in the installation result in the failure of the compressor and other important parts of the air conditioning system.