The use of trunk piping in the heating system is relevant only for small length pipelines. If the scheme is designed for a large house, it is recommended to use a collector coolant supply system. Its main element is a distribution comb for heating: installation, calculation, design, operation principle must be studied before installation.

The purpose of the distribution comb

What is the comb for heating made of polypropylene or steel for? Its main task is to ensure uniform circulation of hot water along individual circuits. It is the main element of the distribution unit, installed immediately after the boiler and in front of the safety group.

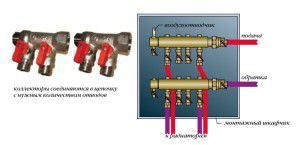

It is a pipe, with several pipes located on its surface. The coolant entering the input channel is distributed along the heating circuits. According to the same scheme, the cooling water returns to the boiler. For the practical implementation of this scheme, it is necessary to install a heating comb on the inlet and return pipes. As a result, this will lead to an improvement in the following system parameters:

- Normalization of pressure, improvement of coolant circulation;

- By installing shutoff valves on the inlet and outlet manifold, the volume of hot water in each circuit can be adjusted. This will lead to lower energy costs;

- In case of failure of radiators or other heating elements, repairs can be done without a complete stop of the boiler. To do this, just turn off the desired circuit.

Applying this principle of operation of the heating comb, you can optimize the thermal regime of the system, as well as set the required temperature level in each room separately.

Installation of the comb is not practical in houses with a large area of up to 100 m². For them, the best option is a two-pipe or single-pipe heating system.

Installation of the comb in the heating system and its calculation

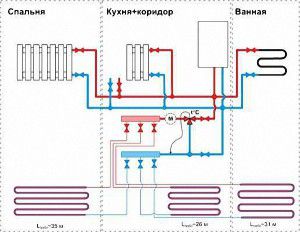

The installation location of the distribution comb in the heating system depends on its purpose. Most often it is used to organize multi-circuit heat supply. However, in addition to this, it is an indispensable element of a water floor heating.

Before proceeding with the installation, a calculation of the heating comb should be performed. The main objective of this process is the uniform distribution of pressure along the heating circuits. If the system is a complex circuit of highways - it is recommended to make a calculation using special programs. For a simple system with up to 5 circuits, the principle of equal sections can be applied.

N0 = N1 + N2 + N3 + N4

Where N0 - diameter of the collector,N1, N2, N3, N4 - sections of its outlet pipes.

The same calculation scheme is used in the manufacture of a heating comb with one's own hands. It is important that the sizes of the input and output collectors match. It is noteworthy that the standard device of the heating comb does not have requirements for its shape. Those. it can be either round or square. The basic principles of installation of collector heating are as follows:

- To improve circulation, we recommend installing pumps for each circuit. In this case, the distribution comb of the heating system should not provide synchronization of the pumps;

- If the unit is located in the boiler room - the installation of a protective box is optional.An exception is the installation of a comb for heating from polypropylene in the underfloor heating system;

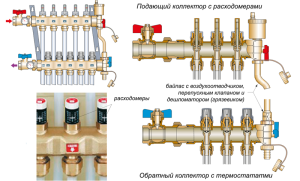

- To adjust the volume of the coolant, it is necessary to install on each inlet and outlet nozzles control valves - inlet valves and balancing flow meters;

- When planning the installation of the heating comb, the presence of a safety group on the distribution unit should be considered.

It should be remembered that these are only general recommendations that can be changed and supplemented depending on the specific parameters of the heating system.

In addition to these rules, experts advise when calculating the heating comb to take into account the difference in the length of the circuits. It is recommended to draw up a diagram so that their length is approximately equal.

To reduce energy consumption, a mixing unit can be installed in the heating comb device, which, in turn, will reduce heating costs.

DIY distributor for heating

Given the high cost of collectors, the question remains - how to make a comb for heating yourself. Knowing the principle of the collector, it may seem that it will not be difficult to make it - the main problem arises when selecting components. One of the best materials are steel pipes of square and round cross-section. However, it is not always possible to work with them at home - this will require a welding machine.

An alternative way is to make a comb for heating systems from polypropylene pipes. To do this, tee joints and a welding tool are required to align them. The diameter of the inlet pipes is recommended to choose the largest possible, taking into account the principle of calculating the heating comb. Those. if the diameter of the pipes in the circuits is 20 mm - this is the same parameter for the main body of the collector should be at least 3 times larger.

To make a heating comb with your own hands, you will need to perform the following steps:

- Measure the distance between the inlet and outlet branch pipes.

- The size of the collector housing should be 10-15 cm greater than the measured distance.

- Cut the pipe according to the dimensions obtained and install branch pipes on it to connect the circuits.

- Check the tightness of the resulting structure.

It should be noted that before making a comb for heating, you need to check the possibility of its installation for a particular system. The problem may be in thermal conditions - polypropylene connecting fittings do not have reinforcement. Therefore, when the temperature is exceeded, their partial depressurization is possible.

It is important that the throughput of the structure is not less than that of the pipe leading from the boiler.

An alternative to making your own strokes may be to purchase a ready-made case. Its cost depends on the number of inlet pipes and can vary from 1400 to 1950 rubles.

Additional equipment

After making the heating comb with your own hands, it is tedious to think about installing additional elements. They are necessary for regulating fluid flows along the system circuits.

Control valves

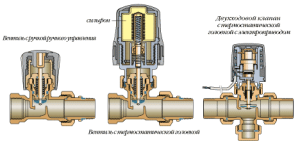

This is a mechanical or automatic shut-off valve, which restricts the flow of coolant through a specific branch pipe of the distribution comb in the heating system.

The easiest option is to install the valve and constantly adjust the flow of hot water in manual mode. This will be inconvenient, moreover, it will not protect the system from overheating. In a small circuit, it is best to install mechanical thermostats that change the position of the restriction rod depending on the temperature of the coolant.

A more expensive version of the regulating device is servos.They are mounted on shut-off valves and can be connected to external temperature sensors or a programmer. Despite the high cost - their presence in the device of the heating comb will lead to almost complete automation of changes in the thermal regime of the system along its contours.

Flow meters

They are mounted on a return manifold and are necessary to limit the flow of water from a particular heating circuit.

Unlike a temperature regulator, the level of water flow is measured not depending on temperature, but on the set parameters. Using the rotary mechanism, the conditional passage in the return pipe is regulated, and the value of the volume of water is displayed on a glass flask.

An additional, but not necessary element in the manufacture of the heating comb is a mixing unit. It connects the inlet and return heating pipes, and a two or three-way valve is installed to regulate the percentage of hot and cold water. It is controlled by a servo drive, to which signals from the temperature sensor are received. If the degree of heating of the coolant is high, the influx of cooled water increases.

To improve the performance of the distribution comb, it is recommended to install a hydraulic arm. This is true for multi-collector systems.

The video shows an example of manufacturing a steel heating comb: