During operation of the heating system, the volume of coolant will inevitably decrease. In open circuits, this process is faster, in closed circuits - much slower. When a critical level of falling drop is reached, the efficiency decreases significantly, and emergency situations can also occur. To minimize such risks, heating system recharge is needed: valves, pumps, units and circuits are selected according to a specific type of system.

Basic rules for arranging heating recharge

What is the reason for the decrease in the volume of water in the pipes? The main source of leakage is the excess of the temperature regime. As a result of this, a critical expansion of the liquid occurs, after which its excess in the form of steam leaves through an air vent (closed circuit) or an open expansion tank (gravity).

The installed automatic heating system make-up compensates for the lack of water by adding the required volume to the main. But this is not the only case when the prompt addition of coolant to the system is required:

- Removing air jams. As a result of the opening of a Maevsky tap or air vent, some of the liquid will inevitably exit the system. In a closed circuit, a pressure drop will occur, to which the automatic heating system recharge should respond;

- Micro leaks. The loose fit of the pipe joints and the loss of sealing even at a small level will lead to a gradual decrease in water volume. Identifying such defects is difficult, but necessary. The automatic valve for recharging the heating system will work only after the pressure drops to a minimum level;

- Carrying out repair or maintenance work;

- The formation of corrosion on the walls of metal pipes, which leads to their thinning and, as a result, an increase in internal volume. At first glance, this is an insignificant factor. But if recharge of the closed heating system is not installed, pressure will gradually decrease and air jams will begin to form.

What should a heating system make-up device consist of? It all depends on the type of heating circuit. Also, the design of adding a coolant to the system is affected by its characteristics: pressure, temperature operation, line circuit, number of heating circuits, etc.

For the central system, a refill unit with a pump cannot be installed. This will lead to a change in the parameters of the entire circuit, which will affect work efficiency.

Open heating system make-up

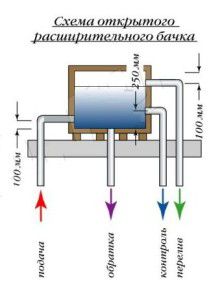

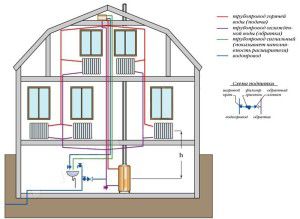

Features of an open or gravity heating system is the absence of increased pressure in the pipes. Therefore, an indicator of a decrease in water in the system may be an improved design of the expansion tank. It should be located at the highest point of the highway.

In this case, the heating system of a private house is replenished only when the liquid level in the tank decreases. This will be indicated by the absence of water pressure in the control pipe. Usually, its outlet is installed in the bathroom or in the kitchen. To prevent constant flow, shut-off valves - valves are mounted. If there is no flow during the test opening, you need to add water to the system.

To do this, the next element of the heating system recharge for a private house is needed - the node connecting the main with the water supply.

Structurally, the node should consist of the following elements:

- Ball valve - it is intended for opening (closing) supply of tap water to heating;

- Filter. Since the quality of the water does not always meet the requirements, it is necessary to clean it from impurities and debris. Subsequently, they will become the main reason for the formation of limescale;

- Check valve - prevents the movement of water from the system to the water supply. This situation can happen in the absence of water in the water supply.

Using this scheme, it is possible to recharge a closed heating system. However, you must first install an air vent to remove excess air. For the correct addition of water, it is necessary that the level of heating of the coolant is minimal. This is especially true for systems with natural circulation. There is a high probability of the reverse movement of cold liquid to a working boiler. This can lead to damage to the heat exchanger due to a sharp temperature drop.

The simplest device for feeding the heating system may consist of a conventional storage tank. However, in this case, the liquid level in it will have to be monitored visually.

Closed heating system make-up

For a closed system with high pressure, the above scheme will not work. In this case, installation of automatic make-up of the heating system is necessary. The principle of its operation is to add a coolant while decreasing the pressure indicator below the minimum level. The simplest scheme can be done independently. It includes a ball valve, a pressure gauge and a gear for recharging the heating system. The latter is the main element in this system. About the principle of its work needs to be told in more detail.

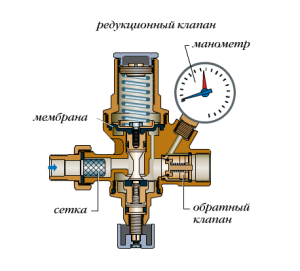

It consists of the following components:

- Adjusting unit with spring on the stem and diaphragm. Located at the top of the structure;

- Locking pad to limit fluid flow from the feed pipe;

- Non-return valve preventing the flow of coolant into the water supply system.

Using the control unit, the minimum pressure in the heating system is set. In this case, the coolant acts on the membrane, preventing the stem from dropping down. As soon as the pressure drops below a critical level, the stem will drop under the action of a spring. Thus, the damper will open and water from the water supply pipe will flow into the heating system. After normalizing the pressure, the rod will return to its original state and the flow of fluid will stop.

Installation of the heating system feed reducer is carried out on the return pipe before entering the boiler, for further heating of water in the heat exchanger. This is due to the minimum value of internal pressure in this section of the system. If the system has a circulation pump, the installation of the automatic make-up system of the heating system is carried out in front of it. Otherwise, during the operation of the pump, surges in the coolant pressure are possible, which will lead to a false activation of the pressure reducing valve.

To regulate the flow of water to recharge the heating system, you need to use a valve with a locking pad. The volume of water passage can be from 5 to 12 l / min, depending on the set value.

Possible problems when recharging a closed system

At first glance, such an automatic heating system make-up unit is ideal for a closed system with forced circulation of water. However, in the practical application of the unit, one may encounter the following problems.

Reduced pressure in the water supply

According to the standards, the pressure level in the water supply network should not exceed 4 atm. The same value for heating is usually not more than 3 atm. Those.theoretically, when opening the valve seat, a stream with high pressure from the water supply will enter the heating main. However, in practice this does not always happen. This is especially true for autonomous water supply systems. If the pressure in the water pipe is lower than in the heating pipe, the coolant will not flow, but will decrease from the system.

To solve this problem, the installation of a non-return valve is required, and also a pump is needed to feed the heating system. The latter will create the desired pressure level in the feed line. To enable it, you will need to install several additional elements together with the heating system recharge valve:

- Pressure gauges with switch-on relays connected to the pump;

- Pressure valve opening sensor;

- Storage tank.

This node automatically feed the heating system will work as follows. If the valve opens and the pressure on the pressure gauge is lower than critical, the circulation pump will automatically turn on to recharge the heating system. In the absence of water in the water supply, it will come from the storage tank.

Membrane sticking

This problem is typical for long-term operation without turning on the heating system feed circuit breaker. Regardless of the material of manufacture, a slight calcareous deposit will appear on the inner walls of the gearbox. It will prevent the valve from opening, resulting in an emergency.

To avoid this, you should open the stock manually before starting the system, and then at least once a month. This will make it possible to verify the system is working, and will also help prevent a critical drop in the level of hot water in pipes and radiators.

It is best to use stainless components to organize the heating system. Valves, pumps, units installed according to the scheme will then last much longer. Brass products are slightly inferior in their performance to steel from stainless steel.

Installation and configuration tips

The normal operation of the machine to feed the heating system largely depends on the installed elements and its location on the diagram. It is necessary to repeat once again that the assembly of the unit should be performed only on the return heating pipe. Otherwise, false alarms of the system are possible, which is incorrect.

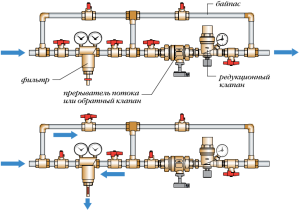

Bypass

In the automatic feed of any heating system, breakdowns of individual components are possible. There is a likelihood of reducing the coolant or the impossibility of adding it to the pipeline in another way. Therefore, the unit should be installed on bypass.

With such a recharge scheme during its breakdown or the need for preventive maintenance, it is possible to manually supplement the heating system. However, this must be done very carefully, since the probability of exceeding the critical volume of water in pipes and radiators is high, which will lead to a sharp increase in pressure.

Procedure:

- We close the shut-off valves on the heating valve feed line.

- We open the shut-off valves on the bypass, ensuring the flow of water.

- We track the value on the manometer, which is not located on the feed line of a closed system, but after it immediately before the pump or boiler.

- As soon as the pressure reaches the desired level (from 1.5 to 3 atm.) - we shut off the taps on the bypass.

Before performing these steps, it is necessary to suspend heating of the water so that its temperature drops to a minimum level. Otherwise, the probability of failure of the heating boiler increases.

Filtration

Since the above schemes provide for the addition of tap water, it is necessary to provide for the installation of a filter system.By default, almost all gearboxes for heating system are equipped with mesh elements. However, they are designed only to retain external impurities of a large fraction. It is best to install a complete coolant pre-treatment system.

In this case, you can purchase a household kit for drinking water purification, as it performs the required functions. At the same time, the operation of the automatic make-up unit for the heating system will be much more efficient:

- The likelihood of limescale on pipes and radiators will decrease;

- The percentage of air in the liquid will decrease, which will favorably affect the absence of corrosion processes;

- The frequency of mandatory flushing of the heating system will increase.

Following these rules, you can not only optimize the flow of water to recharge the heating system, but also increase the efficiency. If antifreeze is used in heating, it is necessary to add a storage tank with it to the make-up circuit of a private house system. Using an additional pump, the coolant will be supplied to the system. It is important to constantly monitor the level of antifreeze and periodically supplement its volume.

In the video material, you can familiarize yourself with an interesting heating recharge scheme in the presence of an indirect heating boiler: