Sooner or later, any heating system will need to be repaired or modernized. If shutoff and drain valves were installed in a certain area in advance, there will be no problems with this task. However, in this case, you need to know the technology of the work. How is the correct insert made into the heating system: pipes, pumps, circuits, heating elements? First, consider the cases when it is needed.

Rules for installing new equipment

Installing new equipment or replacing a failed one should not affect the performance of the entire system. The correct insertion into the existing internal networks of heating pipelines is carried out with a minimum term for stopping the heat supply to the house or apartment.

This procedure should be performed only in compliance with the following rules and recommendations:

- Minimum coolant leakage. This is especially true for closed systems operating under pressure. In this case, the best option would be an insert into the heating without welding using special couplings;

- Reduce downtime for work. For this, it is necessary to foresee the availability of all tools and materials;

- Saving the heating parameters of the room, taking into account new equipment for modernization. Efficiency should not decrease, the temperature regime should change, unless this is planned in advance;

- Safety. In particular, this applies to cases when the insert is inserted into the heating system.

To do this, it is recommended that you first study the existing heating scheme in advance and develop a plan for its modernization or repair. For example, the insertion of an electric boiler into the heating system is carried out not only according to the recommendations of the manufacturer, but also taking into account the optimal location of the equipment. Consider common types of work that you can do yourself.

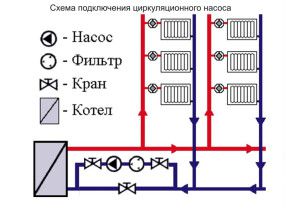

Insertion of the pump into the heating system

This device is designed to improve the circulation of the coolant in the system. For private houses, the pump is most often inserted into the heating if the speed of the water in the pipes is unsatisfactory. It is noteworthy that such a need may arise not only for closed, but also for open systems.

First you need to determine the installation location. If you carefully read the operating instructions for any model - you can not see clear recommendations from the manufacturer. The main question: where is the pump inserted into the heating system - before or after the boiler? The optimum temperature mode of operation of this device is usually 110 degrees, which makes it possible to install it immediately after the boiler. However, the following factors that directly affect the efficiency of the pump must be considered:

- It should be located at the lowest point in the system;

- Temperature fluctuations of the heat carrier are minimal;

- The installation site is recommended to choose as straightforward as possible.

Based on these conditions, the insertion of the heating pump into the old system is carried out directly in front of the boiler. This ensures not only a uniform supply of water to the heat exchanger of the boiler, but also increases the service life of the pump.

Before starting work, it is necessary to reduce the level of heating of the coolant to a minimum. The difference in the insert technology is only in the material used to make the pipes.

Installation of the pump in a steel pipe

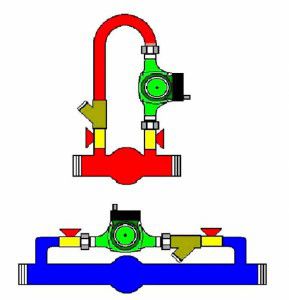

Installation of the pump is not recommended in the pipeline. Parallel installation is best. To do this, it is necessary to make a b-shaped design of pipes, the middle part of which will be occupied by the pump.

The diameter of the line should correspond to the main parameters. Be sure to install shutoff valves to shut off the coolant. Correct insertion of the circulation pump into the heating system can be performed without a welding machine. To do this, you must perform the following actions:

- Block the movement of the coolant in the installation area. If the valves are not installed in the system, in most cases it will be necessary to completely drain the water from the pipes;

- Make two mounting holes in the return pipe. When connecting the pump to the heating system, carefully check the dimensions;

- Install adapter couplings;

- Connect an already assembled circuit with a pump.

It is recommended to include a non-return valve in the complete set of the latter. Thus, tapping any pump into the heating will not affect the direction of fluid flow in the pipes.

Installing the pump in plastic pipes

For polymer pipes, the task is simplified. This is due to the fact that the pump insertion scheme into the heating system can be carried out using a special coupling with a mill. Even if there are no shutoff valves in the work area, it is not necessary to drain the water from the pipe.

Having made the markings on the section of the highway, special valves are installed for tapping under pressure. Then it is necessary to connect the circuit with the pump according to the insertion scheme in the heating system. Using a cutter, holes are made in the main line. They are designed to fit the pump into the heating system. The safety clutch prevents fluid from flowing out of the circuit. But a small amount will still leak out. Therefore, it is recommended to prepare dry rags in advance. After the insertion into the heating system is completed, the joints are checked for leaks, then the boiler can be started.

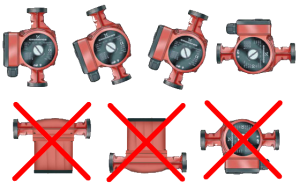

During installation, it is important to pay attention to the following factors:

- The correct location of the pump relative to the direction of fluid flow in the pipes. There are corresponding indicators on the device case;

- The circulation pump must not be installed upside down or at the wrong angle.

The disadvantage of the saddle is its relatively high cost - from 5000 rubles for a pipe with a diameter of 40 mm. Therefore, the insertion of the circulation pump into the heating system can be done using a makeshift adapter. To do this, you will need a conventional coupling with an internal thread and a ball valve. Having assembled this design, the coupling is installed on the return heating pipe. Opening the crane with an electric drill, holes are made in the highway. Then it is important to quickly close the shut-off valves in order to prevent the filling of the coolant. Using this technology, it is possible to insert into the heating without welding for any type of pipe.

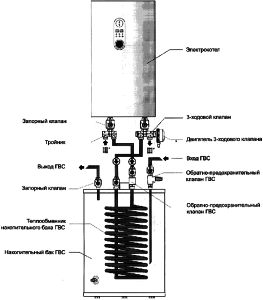

Electric boiler insert into the heating system

Before inserting an electric boiler into the heating system, you must familiarize yourself with the installation instructions. Often the scheme does not differ from the standard ones - the only exceptions are ion boilers, characterized by a small size.

It should be noted right away that illegal insertion into the central heating system of any type of boilers is prohibited. This cannot be done even if the water heating in the pipes is not appropriate. Otherwise, there is a high probability of reducing the efficiency of the system and the failure of the boiler. An appropriate temperature mode of heating can be achieved only in the management company.

When inserting an electric boiler into an autonomous heating system, a strapping should be done. It should consist of the following components:

- Pump.If it is already in the boiler, installation is optional;

- Distribution valve and balancing valve;

- Shutoff valves on an output and return pipe;

- Pressure gauge and thermometer.

A new insert into the existing heating pipe should only be carried out after the main boiler has stopped. Otherwise, it may break it.

If the electric boiler is mounted as an additional source of water heating, you should first correctly calculate its power. The operation of the device should optimize the temperature regime without disturbing it.

Installation of additional heating elements

Often the temperature in the radiators remote from the boiler does not correspond to the optimum. This may be due to improperly designed system or inappropriate temperature conditions. To stabilize the parameters, you can make an insert into the existing internal network of heating pipelines. As an additional heating element, electric heaters are most often used.

Only models specifically designed for this purpose should be used. They are mounted directly in the radiator, since installation in pipes will affect their throughput. When inserting a heating element into the heating system, the following radiator parameters must be taken into account:

- Battery model. Installation of the heating element is possible only in sectional radiators. It runs in the mounting hole of the heating appliance;

- Radius and threaded connection. When inserting a heating element into the heating, not only its length, but also the installation parameters are taken into account;

- Power. The parameters of the main source of water heating in the pipes are taken into account.

It is recommended that models with an adjusting thermostat be selected. This will make it possible to set an individual heating mode for each radiator separately.

The manufacture and installation of home-made heating electric elements is unsafe for the life and health of those living in the house. Only certified factory products must be used.

Central heating insert

In apartment buildings with central heating, the installation of new polymer pipelines is associated with one difficult task - insertion into a metal heating pipe. If you choose the wrong materials and installation technology - there is a high probability of depressurization of the joints.

The problem is associated with rapid rusting of pipes due to the possible enrichment of water with oxygen. Therefore, it is not recommended to use pipes made of cross-linked polyethylene without a special protective sheath.

The insertion technique into the heating pipe is as follows:

- Turn off the water supply. This must be agreed with the management company, presenting them with all the necessary documentation on changing the parameters of central heating in the apartment;

- Mounting adapter. Usually it includes a filter element, a check valve and a counter;

- Joint leak test. Starting water into the heating circuit.

When tapping into the existing internal networks of heating pipelines, the throughput of the new section must be verified. It should correspond to a similar parameter of the entire network. Otherwise, an additional hydraulic load will appear.

Often, such work cannot be done by tapping into heating without welding. A problem may arise when coordinating the installation scheme with the engineering department of the management company. Experts recommend replacing the riser pipes with plastic pipes or weld a metal pipe.

As mentioned above, for central heating the insertion of an additional pump is prohibited. If it is discovered, the owner of the premises may be fined with the obligatory restoration of the previous system parameters.

It must be remembered that any insert into the heating system, regardless of what it will be: pipes, pumps, heating elements, will make changes to the parameters of the entire circuit.Therefore, it is important to first perform a preliminary calculation of power and select the optimal temperature mode of heating. And only after that it is possible to choose a scheme for installing new equipment or replacing old ones.

The video shows an example of using the saddle for emergency connection of the crane: