One of the most important parameters of the heating system is to maintain the direction of flow of the coolant. For this, installation of special fittings should be provided. First you need to choose a check valve for heating: ball, flap, schemes for their installation. Having found out the design and operational features, you can choose the optimal model.

Check Valve Requirements

During operation of the heating system, a difference in hydrodynamic pressure inevitably occurs in certain areas. One of the consequences of this phenomenon will be a change in the direction of flow of hot water. By installing a bypass check valve for heating, you can avoid an emergency and achieve stable operation of the entire system.

What is this device like? Its main task is to prevent the reverse movement of the coolant. It is important to choose the right check valve for the heating system: flap, spring disk or ball. But first, consider the causes of the emergency:

- Uneven cooling of the coolant in the gravity heating system. If the rate of expansion of water in the return pipe is greater than in the main one, there is a high probability of a change in flow;

- Several heating circuits. In this case, it is problematic to ensure uniform pressure inside each of them. Therefore, the liquid will move along the path of least resistance, which is not always the right direction. Example, connecting an underfloor heating water with a mixing unit. If you do not install a check ball valve for heating, then the flow of hot coolant may not flow into the distribution manifold, but into the pipe of the return pipe;

- Complete set of bypass - an intermediate line between direct and return piping for uniform distribution of heat energy on radiators in the system.

Based on these requirements, the check valve of the heating battery should provide unhindered passage of hot water, prevent its reverse movement and not affect the technical and operational characteristics of the system. The latter is considered an impossible task, since in the course of the flow of hot water the valve will create additional hydraulic resistance. That is why the choice of a particular model must be approached more than meticulously.

Installation of a non-return valve on the heating bypass can be done in any spatial orientation. Regardless of the angle of inclination of the structure, it will perform its functions. But this applies only to spring models.

Check Valve Selection Parameters

Regardless of whether a flap check valve was selected for heating or a ball valve, first you need to determine its parameters for connecting to the pipeline. The main rule is the compliance of the bore diameter of the reinforcement of the entire line. Those. if the cut section is 32 mm, then this parameter for the valve should be the same.

Then you need to select the type of connection to the system. Currently on the market there are such models of check valves:

- Coupling. With threaded connection unit. A similar scheme is used for a spring disk check valve mounted in autonomous heating of a private house or apartment. The maximum size usually does not exceed DU-50;

- Flange. Designed for installation on large diameters - from 50 and above. The most commonly used check valve for heating with a ball;

- Interflange. Mounted between pipe flanges, characterized by small dimensions. The best choice is the petal check valve for central heating.

For systems with pipes of small diameters, spring-type coupling threaded models are most often mounted. They are characterized by simplicity of design and reliability. But at the same time, you need to pay attention to the material of manufacture. It is best to install check valves for a stainless steel heating system. They are able to withstand pressure up to 10 atm., The surface practically does not rust. However, their cost is the highest, which is due to the features of manufacturing.

Brass valves are less reliable, but are quite suitable for a home autonomous heating system. This material rusts very slowly, but in comparison with stainless steel it is characterized by lower mechanical strength. Often a check ball valve for heating up to 32 mm in diameter is designed for a maximum pressure of 5 atm.

For central heating, the best option is to install cast iron products. Despite their massiveness and heavy weight, they can withstand critical pressure values, which is one of the mandatory parameters of valves in this class. Alas, the specifics of manufacturing does not allow the production of cast-iron check valves for a heating system with a diameter of less than 40 mm.

Once you have decided whether a check valve is needed in the heating system, you can proceed to the choice. Consider the main design features and installation conditions for each of them.

For a single pipe heating system with one circuit, a check valve is often not needed. The only exceptions are bypasses for radiators, where its installation is required.

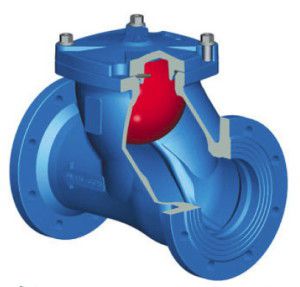

Ball check valve for heating

A truly universal ball valve for heating is considered. To create a locking mechanism, a sphere is used in it, which, under the action of the coolant flow, rises into a special end pipe. If the pressure level decreases or the movement stops altogether - the ball goes down, blocking the entire passage. Moreover, its diameter should be equal to the cross section of the pipe. The advantages of using such a mechanism lies in its reliability. The design does not include moving parts or other mechanisms. The probability of failure of the check valve for heating with a ball is very low.

However, it is necessary to take into account its operational features:

- High cost due to manufacturing complexity;

- The working diameter can vary from DN15 to DN. This makes it practically impossible to install them in an autonomous heating system of a private house for a small pipe section up to 40 mm;

- The minimum pressure for raising the ball is usually 25 bar.

Given this specificity, in the vast majority of cases they install a non-return ball valve for centralized heating when laying large highways. Exceptions are autonomous systems with a high pressure indicator - industrial and commercial.

Models with a rubber ball have proven themselves best. It does not form limescale, and a protective shell protects the metal from corrosion.

Petal check valve for heating

Due to the shortcomings of the above model, another type of shut-off and control valves was developed - flap check valve one or two-leaf for heating. Steel plastic is used as the main mechanism for regulating the direction of fluid flow.The hinge system provides free movement of the flaps under the influence of the pressure of the coolant.

Depending on the design, two types of flap check valves for heating are distinguished - double-leaf and rotary. In the first case, the rotary axis is located in the middle of the highway, and steel plates are installed on its sides, which serve as the valves. For models, the valve is mounted on a special indoor platform. In this case, the hydrodynamic losses will be minimal.

Petal double-leaf check valves are often manufactured with interflange fastening, as their design allows installation at the minimum permissible gaps between the pipes.

Swing models of the casement type are most often made of cast iron alloy for pipelines of large diameters - from 50 mm.

Installing a flap model will ensure maximum throughput of the pipeline in this section. This is especially true for a swing structure.

Spring disc valve

For an autonomous system of a country house or apartment, another check valve is required for heating. The pipe scheme for them rarely provides for the installation of large cross-sections of highways. Therefore, all of the above models cannot be installed due to the dimensions and restrictions on the mounting diameter. As an alternative, a spring-loaded check valve, also installed on heating batteries, has proven itself well.

For its operation, a central rod with a spring is provided, which abuts against the disk limiter. Under the influence of the hot water pressure, the disk is displaced and the coolant flows further along the line, in case of a change in the flow direction, the saddle does not allow fluid to flow in the opposite direction.

The advantages of mounting this type of check valve are as follows:

- Large selection of mounting diameters - from 16 to 40 mm;

- Low cost;

- The coupling method of connecting to the system, which is most acceptable for private autonomous heating.

The disadvantage of the spring valve is the likelihood of scale formation on the disk and its jamming after a long period of inactivity. This will lead to the formation of an artificial plug in this section of the pipeline, which will prevent water from circulating further along the heating circuit.

Before purchasing, you need to pay attention to the material of the rod. For heating, you should buy models with a brass or steel core.

Check Valve Installation

Where does the main line need a non-return valve in the heating system? They are necessarily equipped with all types of bypasses for radiators and boilers. Also, a non-return ball valve for centralized heating is mounted at the branch points of the pipeline.

When installing autonomous heating when installing a spring valve, you need to pay attention to the following nuances.

- On the case, the direction of movement of the coolant must be indicated;

- To improve waterproofing, you need to use special paronite gaskets or windings. But they should not artificially reduce the working section of the shutoff valves.

In addition, a non-return valve for heating is used for a water floor heating circuit. It is mounted on a pipe from the return line for mixing with hot water.

It is best to purchase stainless steel spring valves. Their average cost is from 125 to 750 rubles, depending on the diameter. Brass models have proven themselves for low-temperature heating systems.

The video shows an example of the operation of a non-return valve in a heating system.