Modernization of heating equipment makes it possible to heat a house efficiently and without extra costs. Modern boilers have high efficiency, they are economical and reliable. Units operate on various types of fuel, making it possible to choose the best option. A popular model of floor-standing boilers is the Bear series from Protherm.

Distinctive features of coppers Bear

The efficiency of the autonomous heating system is determined by the boiler. The products of the Czech company Proterm are popular among Russian consumers. The boiler equipment of this brand is reliable, durable, it is offered at an affordable cost. Among the gas units, the Medved boiler is distinguished by its large dimensions, considerable weight and unpretentiousness in operation.

All models in the series are boilers with floor mounting. The fuel for them is natural or liquefied gas. This is the most profitable and economical energy resource. Units are equipped with a sectional cast-iron heat exchanger. This structural element transfers the thermal energy of gas combustion to the water circulating in the circuit. Cast iron is resistant to corrosion, the thick walls of the heat exchanger do not fade and rust for a long time.

Heating equipment is available in a single-circuit version. It is designed only for home heating. To increase product functionality, the KLZ model is equipped with a built-in boiler. To other units of the tank for heating water are connected optionally. Gas combustion air is taken from the room. The combustion products are sent to a special collector connected to the chimney. In the absence of draft, smoke accumulates in the upper part of the structure, heating the thermostat. After the sensor is triggered, the gas supply stops.

Protherm offers 4 product lines under the general name Bear. They differ in design features and power parameters. Experts note the high quality of the assembly of floor gas units. They rarely break down and get into service centers for repairs. Cauldron Proterm bear is significant in weight. The mass of models with a capacity of 50-60 kW reaches 200 kg without water. Given their size, a separate room and a solid foundation for the installation of equipment will be required.

Specifications

Key equipment parameters:

- maximum pressure - 4 bar;

- noise level - up to 55 dB;

- coolant temperature - 85 ° C;

- average efficiency - 91%;

- power - 20-60 kW;

- class of protection against electric shock - IP-40.

Functional burner provides 2-step power control. This allows you to save bottled gas and change the temperature of the coolant in the circuit. For normal operation of the equipment, the water in the circuit must have a pH value of 7. To prevent mechanical impurities from damaging it, a filter is mounted on the pipe.

The electric ignition installation simplifies the operation of the units, but models with a piezoelectric element are more relevant for frequent blackouts.

Advantages and disadvantages

Proterm products are popular in 25 countries. The demand for equipment is explained by its many advantages:

- In the manufacture of durable and durable materials are used - stainless steel and cast iron.

- Eco-friendly heating option does not pollute the environment.

- Equipment operation is controlled by microprocessors.

- Units have a built-in security system. They provide functions: anti-freezing, protection against blocking the pump, sensor for the exit of combustion products and boiler overheating.

- A wide range of products provides the opportunity to find an option suitable for an individual heating project.

- Availability of management and maintenance. An informative display and thermostat help control processes.

The advantages of equipment include its versatility. Depending on the power, the models are installed in country houses, apartments, cottages, institutions and industrial workshops.

The lack of units is the lack of the ability to connect control via a remote control. This feature is only available on the more expensive Proterm models. One more minus - you will need free space for the boiler.

Installation and Maintenance Rules

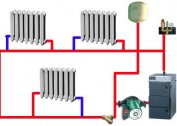

The gas boiler Protherm Bear is mounted on a solid and non-slip base. Its installation is carried out according to state requirements and standards, as well as taking into account the manufacturer's instructions. The room where the structure is located should be well ventilated. The recommended temperature in the boiler room is not lower than 5 ° C. If the models do not have their own built-in expansion tank and safety valve, then the equipment is mounted in the heating system.

Before starting, the water pressure is checked by a pressure gauge, then the gas supply valve opens. By turning the ignition burner knob, the boiler is put into operation. Its work occurs automatically, according to the set parameters of the thermostat. If the unit shuts down, the burner must be extinguished. Once a year, before the start of the heating season, maintenance is carried out. The condition of the burner, emergency thermostat, the integrity of the chimney system is checked, the heat exchanger is cleaned. The owner must measure the water pressure in the circuit once a week. If the indicators drop, it is necessary to fill the liquid into the system.

Installation and commissioning of heating equipment must be carried out by a specialist. Only in this case will the manufacturer's warranty be recognized.

Varieties of boiler models Bear

The heating equipment under the Bear brand is produced not only by the Czech company Proterm, but also by the Russian concern. The domestic manufacturer offers solid fuel boilers for houses with a water heating system. They have a high efficiency of 91%, uncharacteristic for solid fuel units. In the catalogs of enterprises or specialized stores, you can choose the best option.

Gas

Floor gas boilers Protherm Bear in the company catalog are presented in four series.

In the line Klom 4 models with power from 20 to 50 kW. The stationary boiler is equipped with a sectional cast-iron heat exchanger and a burner that allows you to adjust the heating level. To provide a home with hot water, you can connect a boiler. The removal of gas from the combustion products is natural, but when the turbo box is installed, it becomes forced. Convenient electronic ignition system. The units are controlled by buttons or from the display.

Aggregates Series Klz are designed for operation on main and liquefied gas. Their feature is a built-in boiler of 90 liters. Modulation burner smoothly regulates the power of the equipment. The maximum temperature of the heating circuit is 85 ° C, domestic hot water - 70 ° C. The unit is equipped with a self-diagnosis function, flame control, electronic ignition system. If desired, the owner connects control from an external temperature sensor. There is a timer for heating the water and a function to turn off the equipment when the specified parameters are exceeded.

Boilers Proterm 40 Plo and other modifications of the line are non-volatile. A piezoelectric element is installed for ignition. Models with two-stage power control. Boilers are used in private homes and small production halls.They are equipped with a set of thermostats to control the operation of the circulation pump. The unit can be used to heat water, if you connect an external boiler with a volume of 80-200 liters to it. A cast-iron heat exchanger ensures long-term operation of the equipment.

Boilers Protyerm Bear Series TLO are low temperature installations. The models are non-volatile, piezo ignition is installed for the burner. The power of the units is 20-50 kW. The cast-iron heat exchanger has from 3 to 6 sections. Due to the inertia of the metal, it slowly cools. Thanks to its corrosion resistance, it lasts a long time. The boiler is easy to maintain, combustion products are discharged naturally. Water is used as a heat carrier.

- KLZ 17

- PLO 30

- TLO 50

The manufacturer prohibits pouring antifreeze into the system.

Solid fuel

For rooms with an area of 40-400 m2, the Bear company offers equipment that operates on wood. Series Comfort - a design of two steel cylinders between which the coolant is heated. Two doors are installed in the case, through one the firewood is laid, ash is removed from the second. The performance of the equipment is controlled by a safety group of thermometer and manometer. Power of coppers is from 8 to 40 kW. There are enough fuel bookmarks for 6-31 hours. Among the models there is an option for a country house and a cottage.

For rooms with an area of 40-400 m2, the Bear company offers equipment that operates on wood. Series Comfort - a design of two steel cylinders between which the coolant is heated. Two doors are installed in the case, through one the firewood is laid, ash is removed from the second. The performance of the equipment is controlled by a safety group of thermometer and manometer. Power of coppers is from 8 to 40 kW. There are enough fuel bookmarks for 6-31 hours. Among the models there is an option for a country house and a cottage.

Long burning

Universal solid fuel boilers for long burning will provide stable heating of the coolant with minimal human involvement. They are able to function on one tab of fuel for up to 5 days. Continuous operation is possible thanks to top-down combustion technology. Series Aggregates Comfort-G and KBp-G presented in the range of capacities from 8 to 40 kW. Copper of long burning Bear gives an efficiency of 90%. Thanks to the use of various types of available fuel (coal, firewood, sawdust), the equipment quickly pays for itself. The use of durable steel in the production ensures long-term operation of the units.

Gas and solid fuel boilers Bear are economical and reliable in operation. They relate to the middle and budget price segment.