The comfort of a person's stay in the room, whether it be an apartment in a high-rise building, a private house, a workshop or an office, largely depends on the temperature of the surrounding air. At the same time, it is impossible to do without an effective heating system in the cold season. And if in urban conditions and in the workplace this problem is solved in a centralized manner, then in the houses of private buildings, the presence of an autonomous heating system is mandatory. As a rule, its basis is a solid fuel, electric or gas boiler. Those who are planning to equip their homes with such a heating system should pay attention to the products of the German company Vailant, the boilers of which are famous for their operational reliability and efficiency.

Vaillant Company

Vaillant is known as a leading manufacturer of floor and wall heating boilers operating on different types of fuel (liquefied and natural gas, liquid fuel), as well as instantaneous and storage water heaters. In addition, among the products manufactured by the company's enterprises, there are various types of electrical appliances and control devices.

The company was registered in 1874 by entrepreneur and talented engineer Johan Villant. Initially, he created a handicraft workshop engaged in the installation of plumbing in the city of Remscheid, where the head office of the now world-famous company is still located. After J. Wyllant developed and patented a device in which the water flowing through the tube was heated from the flame of a gas burner, the field of activity of the enterprise changed dramatically.

The world's first gas-fired gas water heater Gas-Badeofen, which later served as a prototype for modern gas boilers with a closed circuit, was manufactured in 1894. It was followed by:

- the first wall-mounted gas-fired water heater type Geyzer (1905);

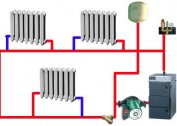

- floor gas heating boiler (1924), which laid the foundation for the creation of a system for the simultaneous heating of several rooms through a central distributor, which became the prototype of the current central heating;

- the system of removal of combustion products through the wall (1959), which allowed the installation of gas boilers in apartments;

- instantaneous electric heater Elektro-Geyser (1960);

- the first wall-mounted single-function gas boiler Vaillant Cirko (1961);

- the first dual-function gas wall-mounted boiler Combi-Geyser VCW 20 (1967), with which it became possible to simultaneously heat rooms and provide them with hot water;

- environmentally friendly fuser (1991);

- The first wall-mounted heating boiler with high calorific value (1995);

- solar thermal systems for heating water (1997);

- individual and intuitive room temperature control system CalorMATIC (2011).

Over the past 125 years, the once artisanal workshop turned into the largest European concern Vaillant Group with branches located in many countries of the world.

Classification of gas boilers

The lineup of gas boilers of the Vailant trademark is very diverse. In order to choose the right heating device that meets all the requirements of customers, they are classified according to their purpose and installation method.

By purpose, gas boilers are divided into two groups - single and double circuit. At the same time, single-circuit boilers (VU models) are intended only for heating, and double-circuit (VUW models), in addition to heating, also provide hot water supply.According to the installation method, the equipment is divided into floor and wall.

The floor boiler Vailant is used for heating houses of a large area. As a rule, it is necessary to equip a separate room for it. In this category, the company offers consumers three options, the power of which is in the range:

- ..56 kW - atmoVIT;

- ..47 kW - atmoVIT exclusiv;

- ..157 kW - atmoCRAFT.

The fundamental details of these models are made of cast iron, which significantly increases their reliability and increases the service life. The air supply to them and the removal of combustion products is ensured by using an open combustion chamber with natural draft (atmoTEC system), as evidenced by the abbreviation atmo. AtmoVIT exclisiv and atmoCRAFT boilers are equipped with two-stage burners, which helps to reduce their natural wear: one stage works continuously, and the other is connected when it is necessary to heat more water.

Among wall-mounted boilers, there are models in which the air supply and exhaust of combustion products is carried out due to natural draft or forced (closed combustion chamber) using a fan (turboTEC system). The nomenclature of wall models includes both single-circuit and double-circuit ones. The power of wall-mounted boilers is:

- 24 kW - the basic atmoTEC pro VUW double-circuit boiler, and its modifications like atmoTEC plus VUW - 20, 24 and 28 kW;

- 24 and 28 kW - single-circuit boilers atmoTEC plus VU;

- 24 kW - the basic turboTEC pro VUW double-circuit boiler, and for its modifications of the turboTEC plus VUW type - from 20 to 36 kW;

- from 12 to 36 kW - single-circuit boilers turboTEC plus VU.

The wall-mounted boiler is used mainly as an addition to central heating, which allows owners to start and end the heating season earlier. It can also be used to heat and / or dry an apartment in wet and cool weather.

Of interest is also the line of condensing boilers (ecoTEC system) boilers with increased power, among which there are also models of floor and wall type. Their energy-efficient technology, compared to a traditional turbocharged boiler, reduces gas consumption by 15%. The range of condensation models Vaillant includes:

Floor standing boilers with capacity:

- from 82 to 288 kW - ecoCRAFT exclusivVKK;

- from 23 to 65 kW - ecoVIT exclusivVKK;

- 25 and 30 kW - ecoCOMPACT VSC INT.

Wall mounted boilers with capacity:

- 80, 100 and 120 kW - ecoTEC plus VU OE;

- 48 and 65 kW - ecoTEC plus VU OE;

- 23, 28 and 35 kW - ecoTEC pro VUW;

- 16, 24, 30, 34, 38 kW - ecoTEC plus VU;

- 24, 30 and 35 kW - ecoTEC plus VUW;

- 24 and 28 kW - ecoTEC pure VUW.

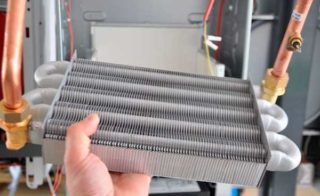

Condensing boilers are units in which heat from the condensation of water vapor from the same gases is added to the heat obtained by cooling the flue gas. Such boilers made it possible to obtain from 12 to 15% of additional capacity from the same amount of gas. In addition, they are more stable in operation with insufficient gas pressure. This is achieved through the use of a fan gas burner and a primary heat exchanger made of acid-resistant alloy steel (stainless steel). True, at the same time, such a heater is 30 ... 50% more expensive than a traditional one.

Features

Vaillant gas boilers from their counterparts are primarily distinguished by high reliability, which is ensured by high-quality protection systems, including:

- continuous frost protection;

- protection of the switching running valve and pump from jamming during long idle time;

- stabilization of the burner when changing gas pressure;

- shutting down the boiler in the absence of traction.

All devices are equipped with an electronic ignition device, as well as troubleshooting systems (LED indication) or self-diagnostics (indication on the LCD).

Electric boilers

In addition to gas boilers, Vailant also manufactures mounted electric boilers of the eloBlock VE 6-28 type, designed for heating, office and commercial premises. They are able to provide consumers with hot water.Electric boilers are an affordable alternative to gas boilers, their small power range (from 6 to 28 kW) in no way limits the area of heated rooms - models with a power of 28 kW allow cascade connection. Their main technical characteristics:

- working pressure of water, bar - 3.0;

- Efficiency,% - 99;

- power supply voltage for 6 ... 9 kW boilers - ~ 220 or 380 V;

- power supply voltage for boilers with power from 9 to 28 kW - ~ 380 V.

Vaillant electric boilers differ from traditional gas boilers in compact dimensions, easy, intuitive control and the ability to work with multi-tariff electricity meters.

Typical malfunctions

Despite the high reliability inherent in all Vaillant brand products, there are several drawbacks. More often than others, users note:

- Plate heat exchangers quickly become clogged with scum, and therefore it is necessary to install special filters that soften water.

- The increased noise level during the operation of the built-in fan.

- Water entering the pump due to insufficient reliability of its seals.

- unstable operation of electronics caused by voltage fluctuations in a centralized power grid. These shortcomings are eliminated by installing a voltage stabilizer.

Properly completed installation work will allow you to avoid trouble during operation.

After installing and connecting the boiler to existing communications, it is necessary to perform the following work:

- check the correct installation of the check valve in the heating system;

- remove air from the heating system;

- Before starting the boiler for the first time, carefully check all settings of the heating circuit;

- carry out a test run, during which to check the functioning of all systems in heating and water heating modes;

- check the operation of all automation, control and protection systems.

The implementation of the listed works is best entrusted to a qualified specialist who has permission to perform such work.

troubleshooting

All Vaillant boilers are equipped with an integrated fault testing system. If any error occurs, the system displays the relevant information on the display screen. Errors that block the operation of the boiler can occur due to unstable power supply or a broken contact in the wire connections coming from the sensors to the electronic module. Such malfunctions can be eliminated by checking the signal lines for the presence of:

- wire breaks or oxidation of lamellas and contact groups;

- short circuits of wires to the housing or between each other;

- wire insulation damage;

- loose contact in the connectors.

After eliminating the identified malfunctions and ensuring the supply of stabilized power, you can reset the error by pressing the "Reset" button.

More serious errors, for example, F20 (overheating), F26 (problems with gas valves), F28 (unsuccessful ignition), F68 (unstable flame), etc. can be caused by various reasons, the search and elimination of which should be entrusted to professionals.

Selection recommendations

Vailant gas and electric boilers are classified as complex, and therefore expensive household appliances. In order to correctly make a decision on the acquisition of a particular variety, the potential owner must clearly and clearly define:

- The place where the boiler will be installed. Wall-mounted models are compact and do not require a special room for their installation. In addition, they are more convenient in operation. But if the owner needs to heat a country house, the heated area of which is more than 300 square meters.m., then the use of a floor gas boiler will be the best solution.

- What should be the system for removing the flue gases generated during the operation of the boiler. If the floor gas boiler will be installed in a new house, it is advisable to equip a special chimney - this will allow you to purchase a cheaper unit with a natural exhaust of combustion products. If this is not possible, it is better to install a turbocharged gas boiler, in which flue gases are forcedly removed. It will also be nice to consider the possibility of using an electric boiler of appropriate power.

- What technical and economic indicators should have a boiler designed for heating a particular room. At the same time, stability of gas and electricity supply in the place where the heated room is located is of great importance. If the gas pressure in the supply network is unstable, the right solution would be to purchase a condensation device that can work with significant fluctuations. In case of power outages, the automation of both gas and electric boilers is turned off and the subsequent start of the units will have to be carried out manually. In order for the boiler to continue to work when the power is turned off, it is necessary to provide a backup power source of appropriate power.

The main technical and economic characteristics of the most popular Vailant wall-mounted boilers are given in the table:

| Boiler type | Model | power, kWt | The heated area of sq.m, no more | Cost, thousand rubles |

| Gas | atmoTEC plus VUW200 / 5 | 20 | 150 | 63,7 |

| Gas | turboTEC plus VUW 242/5 | 24 | 200 | 72,9 |

| Gas | ecoTEC plus VUW246 / 5 | 24 | 192 | 97,5 |

| Electric | elo Block VE9 | 9 | 90 | 57,3 |

All Wilant boilers are lightweight and convenient to operate. It is enough for the user to set the desired temperature, the unit will do the rest itself.