Currently, gas remains the most optimal energy source for creating an efficient and reliable heating system. Along with wall-mounted boilers, floor models are used to complete the heat supply. They have a number of specific features that should be considered when creating the circuit and installation. Consider the main parameters that floor gas boilers for home heating have, manufacturers reviews and reviews.

Selection and operation of gas floor boilers

How to determine the best floor gas heating boilers? First of all, you should pay attention to their rated power, equipment and manufacturer. The heat supply at home should be not only effective, but also reliable.

It should be noted that domestic floor-standing gas heating boilers are currently practically inferior to their foreign counterparts.

Therefore, the choice is mainly determined by the functionality of the equipment and technical characteristics. All gas heating boilers operate on the principle of transferring thermal energy from the combustion of fuel to the coolant.

However, in practice, the value of efficiency and reliability is determined by the following parameters:

- Burner type. Foreign and Russian gas floor heating boilers can be equipped with a single-stage, two-stage or modular burner. It is preferable to choose the last option - the flame intensity is adjusted with great accuracy;

- Rated power. This parameter directly depends on the characteristics of the building: its heat loss, the number of window and door structures;

- Cost. The most expensive are the cast-iron gas heating boilers floor, as this material is best suited for the manufacture of the housing and heat exchanger.

An important role in the proper operation is played by the organization of the equipment installation site. So, floor-mounted double-circuit gas heating boilers must be connected not only to the heating mains, but also to the hot water pipes. Conditions for premises and equipment can be obtained from the Management Company. Upon request for the installation of gas equipment, it is obliged to issue full Technical Conditions. Only then is the gas floor boiler connected to the heating system.

To save money and in the presence of a solid fuel boiler, you can make its modification by installing a gas burner. It is important that the heat exchanger is designed for an elevated temperature level, and the chimney ensures the required draft level.

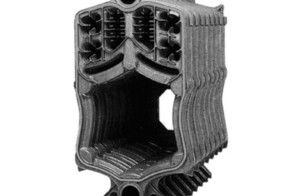

Types of heat exchangers in gas floor boilers

One of the defining parameters for boilers is the material of manufacture of the heat exchanger. Many Russian and Ukrainian gas floor heating boilers are equipped with steel heat exchangers. But to increase the service life and improve the technical characteristics, it is recommended to choose cast-iron models.

For cast iron gas floor heating boilers, a long service life is characteristic. They are less prone to rust and scale on the inner surface of the walls. However, along with this, it is necessary to take into account the important drawback of the cast-iron heat exchanger - its large mass and dimensions.As a result, this affects the size of the boiler.

It is because of this that cast-iron components are rarely included in the package of floor-mounted double-circuit gas heating boilers. The problem lies not in the complexity of manufacturing a double heat exchanger, but in its mass and dimensions. In addition, the consumer should know the following distinctive properties of Russian gas floor heating boilers with a cast-iron heat exchanger:

- Strong impact damage. Cast iron has virtually no ductility. Therefore, under mechanical action, the likelihood of cracks and chips;

- A sharp change in temperature negatively affects. This is relevant in those heat supply systems where a change in the flow of the coolant is possible. Overheating of the case or a sharp change in water temperature will cause a loss of tightness;

- High heat capacity. After connecting the gas floor boiler to the heating system, heating of the heat carrier will be slower than that of a steel heat exchanger. But then, after turning off the gas heating pad, the water will heat up for some time.

In most cases, non-volatile gas floor heating boilers are equipped with steel heat exchangers. For this type of devices, you do not need to be connected to the mains. The ignition of the burner occurs due to the piezoelectric element. In this case, the choice of a steel heat exchanger is determined by its relative cheapness and lower mass. However, the service life of such models is 10-15 years.

At the best floor gas heating boilers, the heat exchanger is made of copper. This is an optimal material, but it is much more expensive than cast iron or steel. Therefore, such models are found less and less.

Types of gas floor boilers

To select the optimal model of Ukrainian gas floor heating boilers or manufacturers from other countries, you should pay attention to the technical data of the equipment. One of them is the rated power of the boiler.

The optimum power for a particular heating system is determined by complex calculations. The heat losses of the house, the climatic features of the region, the recommended thermal regime of the equipment are taken into account.

For foreign or domestic floor gas heating boilers, the power should not be lower than the calculated one. Experts recommend purchasing a model with a small margin of 10-15%. If it is larger, fuel consumption will increase, which will affect the efficiency of the entire system.

Regardless of the choice of floor-standing cast-iron gas heating boilers or their steel counterparts, a number of factors must be taken into account:

- Number of circuits. If there is no need to provide hot water - you can choose a single-circuit model. For domestic hot water, a dual-circuit floor gas heating boiler should be purchased;

- Atmospheric or closed burner. In the first case, air is supplied from the room to maintain the combustion process. But to reduce the likelihood of combustion products entering the living room, it is recommended to purchase models with a closed burner. For them, a coaxial chimney is installed;

- Ability to adjust flame intensity. Modular burners have the best economy. But they are notable for their high cost. For heating a small house or cottage, you can connect a gas floor boiler with a two-stage burner to the heating system;

- Electrical connection. There are a number of non-volatile gas floor heating boilers that do not need electricity. However, their performance is slightly lower than that of electric models. This is due to the lack of electronic control components.

In the vast majority of cases, domestic floor-standing gas boilers for heat supply are technically no different from their foreign counterparts.Therefore, with the same performance characteristics, gas-fired floor heating boilers of Russian or Ukrainian production are most often chosen.

Before purchasing a floor-mounted non-volatile gas heating boiler, you should find out about the availability of service centers for its maintenance. This information is useful in the event of equipment breakdown or for information assistance.

Floor gas boilers Buderus

The products of this German company appeared on the Russian market relatively recently. But in a short time, floor-mounted gas heating boilers Buderus gained great popularity among domestic consumers.

A feature of the company's products is consistently high quality. All types of floor gas heating boilers Buderus are equipped with cast-iron heat exchangers. Thanks to well-thought-out ergonomics, this does not greatly affect the overall dimensions of the equipment. It should also be noted the range of products.

Currently, Buderus offers floor gas boilers with a capacity of 20 to 270 kW. They are suitable for organizing heat supply of a private house, office or industrial building.

Floor standing gas boilers for heating Buderus have the following advantages:

- Ability to connect an external heater tank;

- Change nozzles for using liquefied gas;

- Control settings on the principle of "push and turn";

- Installation of additional modules to optimize the operation of the boiler.

The average cost of a model with a capacity of 20 kW is 80 thousand rubles. Due to the ease of connection, the cost of commissioning for gas boilers of the company is one of the lowest on the market. However, it should be carried out only after completing all permits.

Boilers with power from 73 to 270 kW can operate in low temperature mode. This will save on fuel consumption, which is important when organizing the heating of large rooms.

Zhukovsky floor gas boilers

The Russian manufacturer Zhukovsky Machine-Building Plant offers reliable and affordable heating equipment. Extensive experience (about 40 years) and a modern technical base made it possible to launch the production of a large assortment of Zhukovsky floor gas heating boilers.

AOVG and AKVG series boilers are designed for equipping non-volatile heat supply systems. The company offers several options for models that differ in configuration. The rated power of the equipment varies from 11 to 68 kW. Due to the affordable cost, Zhukovsky floor gas heating boilers have become popular in the heating systems of small rooms - cottages, outbuildings, etc. In addition, they are successfully operated in the heat supply of residential, administrative and industrial buildings.

When choosing Zhukovsky floor heating gas boilers, you should pay attention to their equipment:

- Economy. The equipment uses a Russian-made automation unit;

- Station wagon. To control the operation of the boiler, foreign components are used;

- Comfort. Ability to connect a room thermostat and a remote control.

The main advantage of the boilers of this manufacturer is the affordable cost. One of the most popular models of the "Universal" class with a capacity of 20 kW will cost about 22 thousand rubles.

The heat exchanger in the boilers of the Zhukovsky plant has a tubular shape. Its reliability is provided by the technology of welding seamless steel pipes. The secondary heat exchanger for domestic hot water is made of copper.

Floor gas boilers from Lemarx

The Russian trading and manufacturing company Lemarks offers the consumer one of the widest assortment of floor heating boilers.Using modern technologies and constantly improving production facilities, the company managed to become one of the leaders in sales of heating equipment. That is why Lemarks floor gas heating boiler can be found in the heating systems of private houses and large buildings.

The consumer has the opportunity to choose both single-circuit and dual-circuit models. Automation of floor gas heating boilers Lemarx is made according to the SIT system, which provides a high degree of reliability and a long service life.

There are two types of heat exchangers for boilers - steel and cast iron. For technical and informational support, the company has a large network of representative offices and service centers.

Currently, there are the following types of floor-mounted gas boilers for heating Lemarx:

- Premium. They are made of steel 2 mm thick. Power - from 7.5 to 80 kW;

- Leader. For production, gray cast iron with a thickness of 4 mm is used. Rated power - from 16 to 50 kW;

- Premium Nova. Additionally equipped with automatic 820 Nova SIT;

- Gas truck. The boiler includes the Italian gas burner "Polidoro".

The average cost of the Premium boiler is 26,150 rubles.

A feature of Lemarx boilers is an inexpensive after-sales service. Even after the warranty has expired, the consumer can count on a quality repair of the heating unit.

Floor gas boilers Conord

In the economy segment of heating equipment, well-proven floor-mounted gas heating boilers Conord. In 2012, the Russian company carried out a comprehensive modernization of the production line - Japanese-made equipment Amada was installed. This allowed us to reach a new level of product quality.

Conord floor gas heating boilers come standard with a steel heat exchanger; the body is made of steel sheets 2 mm thick. An innovative component is the design of the smoke collector - it allows the use of heat from carbon monoxide for heating the coolant. An important advantage can be considered autonomous operation of the DHW circuit, which is especially true in the summer.

The range of floor gas boilers for heating Conord can be divided into the following groups:

- Without hot water with automatic SIT;

- Without hot water with thermo-hydraulic automation;

- With hot water with automatic SIT;

- With hot water supply with thermo-hydraulic automation.

The undoubted advantage is more than the affordable cost of heating equipment. The price of one of the most popular models with a capacity of 20 kW with a hot water circuit and thermo-hydraulic automation is 23,000 rubles.

Conord boilers can operate even at low pressures of 0.6 kPa. This advantage can be used when organizing balloon gas heating of a private house or summer house.

Protherm gas floor boilers

Boilers of the Czech company have always been distinguished by good quality and a choice of models. Specializing in the production of heating equipment, Protherm has recently expanded its product range. That is why the floor heating boilers Proterm occupy a leading position in sales.

The company offers several models of floor heating equipment - "Bison", "Bear" and "Grizzly bear". They differ in rated power, equipment and materials used.

All floor heating boilers Proterm are equipped with an open burner. The difference lies in the ability to control the flame intensity - on-off or modular. It is also recommended to pay attention to the material of manufacture of the heat exchanger - cast iron or steel.

There is a certain classification of floor heating boilers Proterm:

- Klz. The boiler has a double-circuit cast-iron heat exchanger and a built-in tank for hot water supply with a capacity of 90 l;

- TLO. Non-volatile model that does not need to be connected to the mains. The storage tank and the DHW circuit are absent;

- Plo. It is equipped with a single-circuit cast-iron heat exchanger and a two-stage burner. As an additional option, a forced smoke removal system can be installed;

- Klom. The model includes a complete set - cast-iron double-circuit heat exchanger, storage tank, modular burner.

To heat large production or commercial premises, it is recommended to use the "Bison" model. It is equipped with an external Lamborghini gas burner with power from 75 to 3500 kW.

The company offers an annual maintenance service for its heating equipment. This minimizes the likelihood of a failure of the gas heating boiler.

Vailant floor gas boilers

The brand of heating equipment “Vailant” is known to the Russian consumer mainly for a wide range of wall-mounted gas boilers. But in the product line, there are also floor-standing gas heating boilers Vailant.

A series of floor heating equipment is represented by ecoVit boilers. They differ from their competitors in the use of re-heating technology using condensate from carbon monoxide. This allows you to increase the nominal efficiency factor of floor-mounted gas heating boilers Vailant up to 98-99%.

All models are equipped with a modular gas burner, a layered DHW water heating system significantly reduces the temperature rise time. Depending on the wishes of the customer, you can choose a boiler with various control systems - an electronic programmer, the ability to connect external temperature sensors.

The advantages of floor-standing gas boilers for heating Vailant are as follows:

- The choice of models with power from 22 to 47 kW;

- The multi-sensor system provides adjustment of the gas combustion process, reducing its consumption;

- Wide burner modulation range from 20% to 100%.

After connecting the boiler, its operation is regulated automatically. The equipment itself adjusts the parameters for the actual pressure and gas type.

Vailant boilers can be cascaded. The maximum number of heating equipment is 4 meters.

Reviews of floor gas boilers

One of the ways to choose the best floor-standing gas boilers for heating the house is a detailed study of customer reviews. But at the same time, one needs to pay attention to their subjectivity, since often information about a malfunction in a survey does not include violations of the operating and installation rules.

- Last year, we purchased a floor gas boiler from Conord. Attracted a small cost, the ability to independently connect to cylinder heating. During the first month of operation, we had to set up the boiler ourselves to set the temperature regime. Although it was best to call specialists. Satisfied with the operation of the boiler;

- After a long analysis, we decided to buy a Lemarks gas boiler for our house. The reason for choosing is the same for the neighbor. We settled on models with Italian automation. Sometimes there are problems with switching on under reduced gas pressure. Otherwise, the boiler works more than well;

- We bought an expensive Protherm boiler with hot water and a modular burner. After a month of operation, the control unit failed. After a call, a specialist arrived at the service center and performed a replacement. It is a pity that during this time (winter and frost) in some places in the house pipes froze.

The choice of the best gas floor boiler is affected by its cost, specific power and equipment. Also, do not forget about the possibility of prompt repair and maintenance. Therefore, first of all, you need to pay attention to the network of service centers from the manufacturer.

The video shows the criteria for choosing a floor or wall gas boiler: