The heating system includes several key components: boilers, radiators, pipes, control and safety devices. Together, they must constitute an effective system for transferring heat from a heated coolant to indoor air. This function is performed by heating devices of heating systems: gas, electric. What is their feature and how to choose the optimal model for a specific heat supply?

Purpose of heating appliances

In the vast majority of cases, air heating in the premises of the house occurs due to the transfer of heat from the surface of the heating elements - radiators, batteries. They can differ structurally, have a different design and a way to raise the temperature on the surface. So, steel heating devices Kermi are designed to complete the water system.

However, despite all the variety of types, several key features of these heat supply elements can be distinguished. All types of heating devices of the heating system can be classified according to the following criteria:

- The used heat carrier - hot water, electric or gas heating element;

- Production material: steel, cast iron, aluminum or bimetal construction;

- Performance: rated power, dimensions, installation method and the ability to adjust the heating intensity.

The choice of a certain type directly depends on the specific heat supply scheme. Bimetal heating appliances are installed for the water system. In rare cases, when using hot steam as a coolant. Wrong choices can significantly reduce heating performance. Therefore, it is necessary to consider the design features and technical qualities that devices for heating premises possess.

Regardless of the type of radiator or any other heating heater, it must be harmoniously combined with the overall interior of the room. It is important to pay attention to the design of the structure.

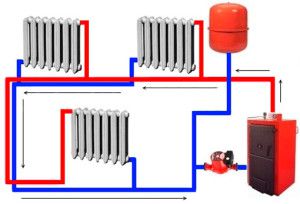

Types of devices for water heating

The largest assortment are heating devices of water heating systems. This is due to the high efficiency of such heat supply schemes, as well as optimal maintenance costs.

All home heating appliances of this type have a similar design. Inside are the channels through which the coolant flows. Heat is transferred from it to the surface of the radiator (battery) and then, using natural convection, to the air in the room.

The main difference that characterizes convection heating devices is the material of manufacture. It is he who largely determines the design of the heating element. There are currently 4 types of radiators:

- Cast iron;

- Aluminum and bimetallic;

- Steel.

Each of them has a number of functional and operational features. They are selected depending on the calculated indicators - each type of heater of water heating systems must comply with the characteristics of heat supply.

An important factor is the type of coolant used. For many bimetallic heating appliances, the use of antifreeze is prohibited.

Cast iron batteries

These are one of the first heating components that were used in heating systems.The choice of production material is due to the relative cheapness, and most importantly - the high heat capacity of cast iron.

This type of heating device for a heating system is currently not particularly popular. The reason for this is the lowest coefficient of thermal conductivity. However, designer cast-iron radiators are often used to create a classic interior in a room.

It should also be borne in mind that it will not be practical to consider them as convection heating devices. The design does not provide additional plates that contribute to better circulation of air masses. In addition to this, it is important to know such features of the operation of cast-iron radiators:

- A large volume of coolant. On average, this figure is 1.4 liters. This contributes to the rapid cooling of hot water, but effective for a small heating system;

- Cast iron appliances for heating rooms are difficult to repair and disassemble at home;

- Great inertness of heating. An increase in surface temperature is much slower than with electric heating appliances.

Despite this, in many old-type houses this type of radiator is still installed. Replacement is carried out only by the residents themselves at their own expense.

Cast iron radiators must be cleaned of accumulated dirt and limescale at least once every 3 years.

Steel and bimetal heating devices

The cast-iron structures were replaced by modern steel and bimetallic heating appliances. Their main difference from the above models is a relatively small channel for the coolant.

However, this does not affect the reduction of heat transfer. Thanks to modern materials with a high heat transfer coefficient, the installation of Kermi heaters significantly reduces the inertia of the entire system. In addition to this factor, other features of the operation of steel and bimetallic radiators for water heating should be taken into account:

- The presence of convection panels to improve air circulation on the surface of the radiator;

- The ability to install heat control and metering devices;

- Affordable cost and easy installation, which can be done independently.

However, with these positive qualities, you need to know the specifics of operating a particular model of a steel or bimetallic radiator. First of all, these are the requirements for the composition of the coolant.

When choosing a battery, you should clarify - is it collapsible or not. This will help to independently adjust the number of sections in a particular heating device.

Electric heating devices

If the installation of a full-fledged water heat supply is impractical or impossible - they install electric heaters for heating. They differ from traditional autonomy and compactness. In addition, there are several types of electrical appliances that have a different principle of heat generation. The main disadvantage of electric heating is the high energy costs. To minimize this, modern metering devices for heating are needed - multitariff electric meters. In the evening and at night, there are preferential tariffs for electricity consumption.

The wiring in the house must be adapted to the maximum loads from electric heaters for heating.

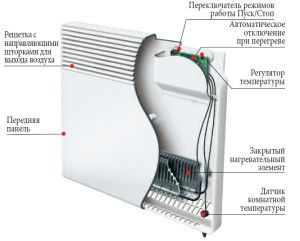

Heating convectors

If there is no autonomous (centralized) heating in a house or apartment, electric heaters are most often installed. Externally, they are similar to standard radiators, but have significant differences in design.

Almost all electric heating devices are used as a heating element in the heating elements. Inside is an element with a high electrical resistance.When a current passes through it, electric energy is converted into heat. For greater efficiency, the heating elements are connected to heat transfer plates made of steel or aluminum alloy.

There are several types of electric home heating appliances:

- Convection. The design is designed for relatively quick heating of air in the room due to the movement of flows through special slots located at the top and bottom of the structure;

- Oil. To increase the area of the hot surface inside the radiator, it is filled with a liquid with a high energy intensity index. The temperature increase is much slower than the above. However, even after turning off the electric heating heater, its surface remains hot for some time.

Almost all models have modern control systems. A mandatory element is an electronic thermostat, which has a temperature sensor for automatically controlling the heating of the convector. Also, the safety of operation did not go unnoticed. When tipping the device, a circuit breaker is activated. There are special models of heating radiators designed to work in wet rooms - bathrooms, kitchens. They have a moisture resistant housing.

| Model | power, kWt | price, rub. |

| COOPER & HUNTER CH-2000 EC | 2 | 3495 |

| NEOCLIMA COMFORTE 2.0 | 2 | 2273 |

| OLMO OL 1000 M | 1 | 1932 |

| NOIROT Spot E-3 1500 | 1,5 | 5838 |

However, for conveying heat to a large house, it is not advisable to install electric convector heating radiators because of the high energy consumption. In this case, it is best to install more economical heating PLEN or IR heaters.

If the total power of electric convectors exceeds 9 kW, a three-phase power supply network with a voltage of 380 V.

Infrared heating at home

To increase the efficiency of maintaining a comfortable temperature in the room, electric heaters are installed that emit thermal waves in the infrared range. Their principle of operation is not in heating the air, but on the surface of objects that fall into the coverage area.

The undoubted advantage of such a technique is the reduction in energy costs. This is because the consumption of IR heaters is 20-30% less than that of similar models with heating elements.

Currently, there are 2 types of heating devices of the heating system operating in the infrared range:

- Film heaters. Resistive conductors are deposited on the surface of the polymer film, which emit infrared waves when an electric current passes through them. They can be mounted both as a heat-insulated floor and on the ceiling of the room - PLEN;

- Carbon Heaters. A carbon fiber spiral is placed in a special sealed glass flask. When you turn on the device, it generates IR waves that heat objects. For efficiency, such devices are equipped with a reflector made of stainless metal or aluminum.

It is noteworthy that the last type of appliances for heating rooms can be installed anywhere in the room. Often they are used to maintain normal temperature outside the house in a certain area.

| Model | power, kWt | price, rub. |

| UFO Star 1800 | 1,8 | 4090 |

| RUNWIN LONDON | 3 | 17150 |

| IR film Luchi, m² | 216 | 1008 |

| IR film MONOCRYSTAL 220L ENP-E, m² | 135 | 673 |

However, for these infrared heating devices of a private house, there are a number of application restrictions. First of all - you can not close the surface of the film. This can lead to overheating and malfunction.

The further the infrared emitter is located, the wider the coverage area. But this increases the degree of heat dissipation.

Gas heating in the room

Analyzing the efficiency of the above devices, the issue of reducing the cost of heat supply remains relevant.Therefore, it is recommended that gas heating appliances be considered as their alternative. These include not only traditional boilers, but also other, no less productive designs.

The simplest types of this type of heaters are gas convectors. It can be connected both to main gas and to a liquefied gas cylinder. The burner is located in a housing that does not come in contact with the air in the room. The supply of oxygen to maintain the combustion process occurs through a two-channel pipe. Through it carbon monoxide is removed.

If a mobile radiator model is needed, Catholic gas heating appliances are of particular interest. They have a slightly different principle of operation. Gas flows from a matrix of small nozzles onto a ceramic surface where it ignites. The result is a catalytic reaction, which is the main source of heat.

What to consider when choosing a gas heater?

- Compliance with safety rules is mandatory. Before connecting the device to the gas main, it is necessary to familiarize yourself with the operating instructions;

- Organization of carbon monoxide removal. The most common consequence of heater malfunctioning is an excess of CO2 in the room;

- Periodic cleaning of nozzles from accumulated soot.

It must be remembered that all heating devices must be adapted to specific operating conditions. This primarily relates to safety regulations and compliance with the operating mode.

In the video you can see an example of making an IR heater with your own hands: