PAROC insulation materials are durable, resilient and flexible, easy to install in the structure. Insulation The park does not shrink during operation, thermal insulation properties are preserved in cold winters due to porosity. The material is manufactured according to the proven technology, undergoes environmental testing.

Technical characteristics of insulation Park

Plates are placed in the appropriate frame without special fasteners. Geometric parameters are maintained precisely, the elastic edge interlocks with the elements of the crate and prevents the appearance of cold bridges.

Material Specifications:

- density varies in the range of 27 - 32 kg / m3 and is evenly distributed throughout the thickness;

- thermal insulation service life without changing indicators - 50 years;

- the level of protection against losses does not decrease with air humidity up to 95%, due to impregnation with water-repellent compounds.

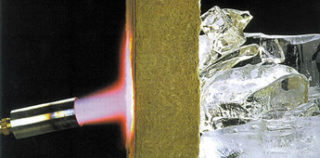

With the use of mineral wool, the Park increases the fire index of the structure, since the material does not burn and prevents the spread of flame.

Product types

The company produces materials based on stone fibers and basalt rocks with the use of improving additives, as well as synthetic.

Products are manufactured in the form of:

- mineral wool, basalt, glass wool plates and mats;

- polystyrene foam extruded and foam products;

- flax insulation;

- plates of increased stiffness (ППЖ);

- foamed polyethylene mats.

The insulation does not shrink after work for 3-4 decades, temporary loads do not leave traces of deformation on the plates.

Mineral wool

Products are distinguished by high sound and heat insulation. The improvement of technology has led to the expansion of the scope of application of Parok mineral wool. The material is used to protect against heat loss in fire hazardous buildings.

Depending on the density, there are types:

- usual;

- semi-rigid;

- hard.

It goes on sale in the form of mats, rolls, plates, sandwich panels and pipes. Fibers in the thickness are arranged horizontally or vertically in layers, collected in corrugated or constitute a spatial structure.

Basalt wool is characterized by high thermal resistance, the indicators of which are similar to a wood thickness of 40 cm.

Characteristics of basalt slabs:

- resists the action of chemicals and mechanical shock;

- tolerates temperature changes without destruction;

- withstands up to 200 cycles of thawing and re-freezing;

- quickly restores properties after drying.

Parok basalt insulation is produced from igneous deposits with the addition of carbonate components to coordinate the acidity index. Bitumen, urea resins and bentonite clays are used as a binder for the fibers.

Thermal insulation Parok based on glass fibers is a type of mineral wool. The raw material is soda, dolomite, sand, limestone, borax. The material is resistant to chemical irritants, it is used in laboratories, harmful production workshops.

Glass wool properties:

- the density in loose form is 130 kg / m3;

- thermal conductivity of the material - 0,032 - 0,052 W / m · K;

- melting point - + 450 ° C.

Glass wool fiber is 4–15 μm long, which is 3–4 times longer than similar elements of stone wool. This determines the resistance to vibration, elasticity and strength of the material.

Stone wool can withstand high temperatures without melting (about +850 degrees). Stone insulation The threshold does not burn, but when heated to a critical temperature it decomposes into dust. Thermal conductivity in the range of 0.035 - 0.039 W / m · K.

Open pores in the structure provide porosity at the level of 0.25 - 0.35 mg / m2 · h · Pa. The density is in the range of 30 - 220 kg / m3, therefore, the physical and mechanical properties of different types are different.

Extruded Styrofoam

It differs by its homogeneous structure, containing gas-filled cells of 0.1-0.2 mm as a basis. Granules of polystyrene and styrene copolymers dissolve in the polymer mass, natural gas is supplied and the particles increase in volume. Heat-resistant types of expanded polystyrene are filled with carbon dioxide. The material is used for insulation of private buildings and in industrial facilities.

Properties of expanded polystyrene:

- low water absorption - accumulates 0.4% of the mass after 10 days in water;

- the density of any kind is 0.05 mg / m · h · Pa;

- fungi and microorganisms do not develop on the surface.

The durability of the extruded polystyrene foam in the construction is 60 - 70 years.

Styrofoam

The material is a foamed plastic mass. The main volume is occupied by gas, low density contributes to poor thermal conductivity. Foams do not belong to toxic materials and are used for insulation of various categories of buildings.

Foam insulation The park is available in several types:

- polyurethane;

- polyvinyl chloride;

- phenol formaldehyde;

- urea-formaldehyde.

Polyfoam is destroyed by the action of dichloroethane, benzene, acetone or the vapor of these substances.

Linen insulation

Flax is used to protect indoor and outdoor structures. Withstands high temperatures, therefore it is used in saunas, baths. The fibers of the natural insulator are bonded with bicomponent polyester components, the mass does not contain formaldehyde and resins.

The material conducts steam and absorbs moisture, but quickly releases it into the environment. During installation, an additional layer of waterproofing is not required.

Slabs

Plates additionally perform the function of soundproofing, in addition to insulation. To bind fibers in bulk, synthetic water-soluble resins are used in accordance with technical and sanitary standards.

Varieties of PCB plates:

- Parok mineral wool on a synthetic binder;

- plates with water-repellent components and without them;

- lacquered with or without trim material.

The material is used for thermal insulation and in the construction of three-layer panels in residential and industrial buildings with a surface temperature in the range +60 - + 400 ° С.

Foamed Mats

Polyethylene foam foams with carbon dioxide during the manufacturing process. It turns out an elastic elastic mass with a closed-pore structure. On sale comes in the form of sheets, rolls, bundles and shells.

Depending on the method of release, they distinguish:

- crosslinked (PES) foams;

- non-crosslinked (NPE) foams.

Crosslinked polyethylene heaters are characterized by multi-stage heating during production, the output parameters depend on the ratio of functional additives and polyethylene.

Scope of application

Thermal insulation boards protect against heat loss on wooden, concrete, brick surfaces. The priority for using Parok Extra insulation is low-rise buildings.

Using material to isolate:

- ventilated facades, door and window frames - basalt, stone wool or polystyrene foam, layer 20 - 30 mm;

- foundations, basements, floors, ceilings - slabs of increased rigidity and basalt mats;

- steel structures, chimneys, door leafs - non-combustible plates ППЖ;

- walls of residential buildings - mineral wool Paroc, extruded polystyrene foam, polystyrene, stone wool.

During installation, workers do not need special protective equipment (exception - glass wool), since insulation does not emit harmful substances and fibers when cutting.

Advantages and disadvantages

The material is easily processed with a simple cutting tool and mounted in the desired position. The insulation is firmly attached to the surface and does not swell under the action of heat, frost and other adverse factors.

Under normal conditions, harmful gases and dust are not detected in the surrounding area. After installation, the insulation Park Extra does not shrink. For transportation, the material is compressed 2 times, and at the construction site straightens in a short time.

The disadvantages include the ability to release hazardous substances at temperatures above + 200 ° C.

Product Range Park

Production workshops in Sweden, Finland, Lithuania and Poland produce a wide range of insulation materials. The company produces thermal insulation for different surfaces:

- Roofs - Paroc UNM 37, Extra Park;

- facades - dense non-shrink plates FAS;

- universal insulators - for roofs of vertical structures, arched surfaces, zero-cycle buildings, pipelines.

Park brand insulation complies with international technical standards and sanitary standards.

Extra Park

The insulation is presented on the market with basalt slabs of 120 x 60 cm in size. It is intended for insulation from floors between floors, coatings, floors and facade parts.

It is characterized by low density and light weight (density 30 kg / m3). The thermal conductivity index of 0.036 W / micron guarantees high-quality heat conservation with a layer of 7 - 15 cm.

Other heat insulators

Paroc WAB-10T It is used for thermal insulation of facades in a ventilated way. The high density of the material (150 / m3) is combined with strength and low thermal conductivity (0.038 W / m · K). Plates are placed on the facade under plaster or siding.

Paroc ROB-60 has a dense texture - 170 kg / m3, which provides strength to the insulating layer. Mats are used for floor insulation, because they withstand 6 tons per 1 m2.

Paroc ROB-80T It has a density of 230 kg / m3, it has no analogues. Strength is ensured by an auxiliary layer of glass fiber. The material is used for flat roofs. The coefficient of thermal conductivity is equal to 0.037 W / m · K, refers to a completely non-combustible species.