Autonomous heating is a complex set of elements, the operation of which in many respects depends on a correctly composed piping scheme. It must meet several requirements: transportation of the coolant, ensuring minimum heat loss, reliable operation and compliance with the operating characteristics of the system. What is the optimal laying of pipes of the heating system: in a private house, in the floor, in the ground?

Rules for laying heating pipes

In the process of designing the system, the rules for laying heating pipelines must be taken into account. They describe in detail the characteristics of highways, both in-house and for district heating.

The main regulatory document at present is SNiP laying of heating pipelines. It is best to use the current edition, and in particular - SNiP 41-01-2003. In addition to the requirements for the organization of district heating, it provides recommendations for laying autonomous heating pipelines.

Regardless of whether heating pipes are laid in a wooden house or built of brick, the following rules must be observed:

- The temperature of the coolant should not exceed 95 ° C, and the nominal pressure - 1 MPa;

- It is impossible to lay pipes in unheated attics, cellars and underground if the calculated temperature in winter is below -40 ° C;

- Compliance with the optimal speed of the coolant, depending on the noise level. The average indicator for autonomous systems is 0.5-0.7 m / s. It directly depends on the diameter of the pipeline, the power of the circulation pump and the heating boiler;

- Hidden laying of heating pipes in skirting boards or in wall gates is carried out taking into account the properties of building materials. The temperature effect from the surface of the highway should not change the appearance or affect safety;

- Pipe material: metal, plastic or metal. At the same time, only steel pipes are necessarily mounted at the outlet and inlet of the boiler. Their length should be at least 0.5 m.

These are general recommendations, compliance with which is mandatory for any method of organizing transport heating pipelines. But for the consumer it is important to know the subtleties of the technology by which the heating pipes are laid in the floor or walls.

In a gravity heating system, the slope of the pipes must be observed. It should be at least 0.3 cm per 1 m. The same applies to the return line leading to the boiler.

Internal routing of heating pipes

Most often, open installation of pipelines is performed. This is the best and most economical way, but first you should install all the components of the system - radiators, batteries, boiler. Only then can the lines be installed. For better sealing of joints, gaskets for radiators should be used. They can be rubber (for low-temperature systems), paranitic (high-temperature) or plastic.

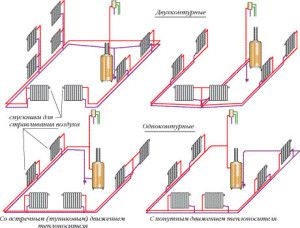

What are the best ways to lay heating pipelines in a one-story building? It depends on the characteristics of the future system.

Underfloor heating

The basic rule for laying heating pipelines under the floor is the maintainability of the system.This means that regardless of the material of manufacture of the floor or pipes, free access to certain nodes of the line should be provided.

These include branches, mounting locations for collectors, corner elements. To do this, install inspection hatches. Their size should provide repair and maintenance of systems, especially if heating pipes are being laid in a wooden house. What else needs to be considered when installing this type?

- Heat loss. If the installation is carried out in a cement screed - it is recommended to use protective materials with a high rate of heat transfer resistance. These include foamed polyethylene, polystyrene foam, etc .;

- If laying heating pipes in a plastic floor is taken into account difference in thermal expansion of materials manufacturing line. To do this, install compensation loops;

- If installation is carried out directly in a heater - it is necessary take into account its operational parameters. In particular, the maximum possible exposure temperature.

| Material | Maximum exposure temperature, ° С |

| Foamed polyethylene | 80 |

| Expanded polystyrene | 90 |

| Styrofoam | 60 |

| Basalt (mineral) cotton wool | 700 |

Installation of piping fasteners is carried out in places of turns, branches. In straight sections, the mounting interval of the fasteners depends on the material of the pipe. SNiP for laying heating pipelines does not regulate this. But to ensure the reliability of the system and reduce noise, it is recommended to fasten steel lines in straight sections every 300 mm, and for plastic ones every 200 mm.

If you use the diagonal method of laying heating pipelines in a one-story building under the floor, you can not install furniture at the passageway. This will lead not only to damage, but also to excessive thermal effects on the screed.

Laying heating under baseboards

To lay the heating pipes in the baseboards, you must first purchase the appropriate consumables. The best option is to buy special skirting boards with installed pipes and heat exchanger plates.

Given the material of manufacture, the cost of such skirting convectors is quite high - from 700 rubles / m. Therefore, most often do the laying of heating batteries in the wall, and then install the baseboard.

Features of such a system organization are:

- It is not allowed to make a strob in a bearing wall. Alternative - installation of pipes under the floor;

- Skirting material should not change properties under the influence of temperature;

- Regardless of the method of laying heating pipelines in a one-story building, the minimum distance between the pipes (direct and reverse) should be 15 cm.

After installation, the joints are first crimped, the tightness is checked during the first test run, and only then is the decorative baseboard installed.

When laying heating pipes in baseboards, you need to calculate the number of rotary nodes. As far as possible, installation of unnecessary corners should be avoided, since because of them the hydrodynamic resistance increases when the coolant moves.

Underground heating pipes

In a private house, it may be necessary to lay heating pipes underground. Such a scheme is used for a stand-alone boiler room or for supplying a heat main to other buildings - a garage, outbuildings, etc.

For the correct installation of heating pipes underground, the following rules must be considered:

- The line may be located above the level of freezing, but then protection against the formation of ice plugs should be provided. This will increase heat loss;

- The coolant supply cannot be at the same level or below the return pipe;

- Protection against possible soil pressure.If it is not foreseen, there is a likelihood of a deformation or destruction of the pipeline.

The correct heating pipe for laying in the ground is pre-selected. It must necessarily have external frost protection. Depending on the temperature of the soil in winter, this can be passive or active insulation.

To improve thermal insulation qualities, it is possible to fill the mounting trench with expanded clay on top of a layer of sand.

Passive heating pipe protection

It is a protective cocoon (shell), equalized over the trunk. It is best to purchase ready-made heating pipes for laying in the ground. On top of the plastic line set a multi-layer "cake". It not only protects against the effects of freezing temperatures, but also shifts the “dew point”. This reduces the likelihood of condensation in the pipeline.

Given the rules for laying pipelines for heating systems, we can distinguish the following types of thermal insulation materials:

- Basalt wool. In addition to good thermal insulation qualities, it is hygroscopic, i.e. moisture from the surface of the pipe will be removed through the wool;

- Foamed polyethylene. It is recommended to use in combination with mineral wool. It forms the primary heat-insulating layer, and basalt insulation protects the trunk from the effects of low temperatures;

- Explicit polystyrene shell. The best option for laying heating pipes to a shallow depth. Sealing is ensured with the help of special locks, which after installation are insulated with tape.

However, unlike laying heating pipelines in the floor, it is necessary to constantly ensure a high coolant temperature. Even the best passive insulation protection can not provide the formation of ice plugs.

For regions with extremely low temperatures, the Uponor Ecoflex Thermo Twin special pipe can be used for outdoor heating lines. In addition to reliable thermal insulation, it is equipped with a heating cable.

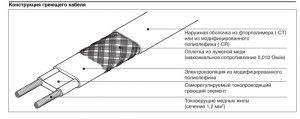

Heating cable

According to SNiP for the external installation of heating pipelines, the possibility of using external heat sources is not provided. But in practice, in autonomous systems with an external line, this is one of the best ways to protect the pipeline from freezing.

The principle of operation of the heating cable is simple - a resistive interaction occurs between the two wires, as a result of which electrical energy is transformed into heat. This scheme can also be used for laying heating pipes in a wooden cottage in technical rooms where the thermal insulation of the walls is low.

It is best to use self-regulating models. Between the conductors is a polymer filler with a varying indicator of electrical resistance. As the temperature decreases, the electrical resistance decreases, resulting in a rise in cable temperature. In this way, the surface of the heating pipe installed in the ground is heated.

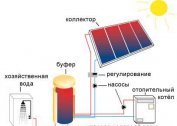

What else needs to be considered when laying pipes of the heating system: in a private house, in the floor, in the ground? If there is a chance of exposure to negative temperatures - you can use special antifreeze instead of water. Its crystallization temperature is below 0 ° C and depends on the concentration. For propylene glycol formulations, the lower limit may be at -60 ° C.

The video material describes the pipes that are recommended for installation for collector heating under the floor: