The selection and further operation of the electric boiler in the heating system is based on a detailed analysis. In addition to technical qualities, the features of the operation of this equipment should be provided. To do this, you need to know all the nuances inherent in electric boilers for heating a private house: choosing, connecting with your own hands the possibility of self-production.

Features of heating with electric boiler

One of the features of this type of equipment is its high cost. Therefore, an electric boiler for heating a private house should be not only powerful enough, but also economical.

Due to the principle of operation, all electric heaters are small. The heating element acts on the coolant (air, water, antifreeze), increasing its temperature.

Therefore, a standard electric boiler for water heating will be much smaller than its gas counterpart. Solid fuel models have the largest dimensions.

Before embedding an electric boiler in a heating system, you should find out its positive qualities:

- Autonomy of work. Modern models are equipped with electronic control and safety units;

- Silent operation. The process of heating water occurs without the appearance of extraneous noise. Exceptions are the electric boiler for heating batteries with a circulation pump;

- Choosing an installation location. Since no carbon monoxide emissions occur during operation, the connection of an electric boiler for heating is performed without arranging a ventilation or chimney pipe;

- No need to apply for installation permission. It is important to correctly calculate the power, since a double-circuit electric boiler for heating a house can only work on a network with a voltage of 380 V. This applies to models with a rated power of more than 18 kW.

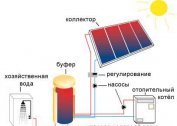

To equip the electric heat supply, it is necessary to adapt the wiring so that it can withstand the maximum power of the boiler. To minimize costs, it is recommended to install two tariff meters and a heat accumulator. The electric boiler for heating and hot water will function at night, heating the water in a heat accumulator. During the day, the accumulated thermal energy will be transferred from the coolant.

To ensure uninterrupted operation, mini electric boilers for heating should be equipped with voltage stabilizers. This will significantly increase the service life of the equipment.

Parameters for choosing electric boilers

At the first stage, it is necessary to solve the problem of how to choose the right electric boiler for heating. Currently, manufacturers offer a number of models that differ not only in design features, but also in functionality. Therefore, the consumer needs to know the basic parameters of choice.

Before choosing an electric boiler for heating a house, you should correctly calculate its power. The operation of any heat supply system is aimed at compensating for the heat loss of the building. Therefore, you must first calculate this critical parameter. You can use specialized programs for this.

After this, the question arises - to purchase a factory model or to make a home-made electric boiler for heating. To solve it, experts recommend analyzing the following factors:

- Device intensity. If you plan to continuously operate the equipment, it is best to purchase a reliable factory electric boiler for water heating. When organizing the heating of a utility room (garage) or a country house with a small area, you can make a home-made boiler;

- Hot water supply. To provide hot water supply, it is necessary to install a dual-circuit electric boiler for heating the house. Making it yourself is problematic, since the design will not have the proper degree of reliability. Installation and calculation of the parameters of the second circuit at home is almost impossible;

- Dimensions. They directly depend on the configuration of the equipment and its capacity. The heat supply of a small house can be done using electrode or induction models. Since it is difficult to make an electric boiler for heating a house of this type, choose schemes with heating elements;

- Mains voltage. Depends on the power of the equipment. Almost all electric boilers for heating with their own hands have a power of not more than 9 kW. This makes it possible to connect to a 220 V network.

But for the consumer, the determining parameter is still the cost of the electric boiler for heating batteries. That is why in recent years there have been many options for the independent manufacture of this type of heating equipment. However, to compare do-it-yourself electric boilers for heating, you should find out the features of the design and operation of factory models.

Often the installation of an electric boiler for heating and hot water in a house is done together with solid fuel equipment. The electric boiler has a low inertia and with its help it is possible to provide hot water in the summer.

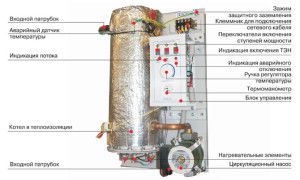

Boilers with heating elements

The classic design of an electric boiler is considered to be the use of heating elements in its configuration - heating elements of a tubular type. They are installed in the tank through which the coolant flows.

To optimize the consumption of an electric boiler for heating a private house, manufacturers mount several heating elements with power from 1.5 to 2 kW. The control unit provides the ability to automatically or manually turn on individual heating elements to optimize energy consumption. In modern models, this function is performed by the electronic control unit. For the best result, it is recommended to choose the right electric boiler for heating with the ability to connect external temperature sensors. This will allow you to configure the operation of the equipment depending on external factors - air temperature in the street and indoors.

Since the main heating element is a heating element - when choosing an electric boiler for heating a house, you should familiarize yourself with their classification:

- Tubular. They have the conversion of electrical energy into heat due to the passage of current through a conductor with a high resistance index. For protection, it is installed in a sealed flask;

- Tubular with heat exchanger plates. To increase the area of heat transfer in mini electric boilers for heating, plates are installed on the flask;

- Electric heaters with a temperature regulator. In factory models, they are not used, but are considered as a heating element in the manufacture of a home-made electric boiler for heating.

An important advantage of factory electric boilers is the ability to choose a fully equipped model, which includes an expansion tank, a circulation pump, and a second circuit for hot water supply. This reduces the complexity of the installation of heat supply and space for it, which is very important for apartments.

If you want to make an electric boiler for heating a house with heating elements, you need to take into account that the lack of water with an active heating element will lead to its overheating and breakdown.Therefore, it is recommended to install a coolant level sensor in the temperature increase unit.

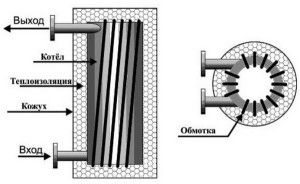

Induction heating boilers

The principle of magnetic induction for heating materials has been used for a long time in the metallurgical and chemical industries. Induction electric boilers for water heat supply appeared on the heating equipment market relatively recently.

In the design of the boiler there is a winding, due to which an electromagnetic field is created. The coolant passes through the core and, due to electromagnetic induction, its temperature rises. This principle allows you to make induction electric boilers for heating a private house of various capacities. In most cases, the models are designed to be powered from a power supply with a voltage of 220 V and a frequency of 50 Hz. To reduce the dimensions of the structure, it is possible to install frequency converters that will increase the specific power of the boiler without a significant increase in dimensions.

The advantages of induction boilers include the following:

- Easy connection induction electric boiler in heating. To do this, it is enough to establish the design and connect the nozzles to the supply and return lines;

- Work reliability. Due to the lack of moving elements, the period of non-repairable service can be from 20 to 30 years;

- Ability to use several types of coolant. You can choose an induction electric boiler for heating for a system with distilled water or antifreeze. This will not affect the performance of the equipment;

- Lack of scale. This is due to the peculiarity of the boiler.

Is it possible to make an induction electric boiler for heating a house yourself? In most cases, this will be difficult, since it is necessary to choose the right material for the winding, the casing and ensure sufficient insulation of the boiler. But the main problem is the tightness of the structure.

Induction electric boilers are widely used for organizing heat supply in large industrial and office buildings. In this case, their dimensions are not a determining factor in the choice.

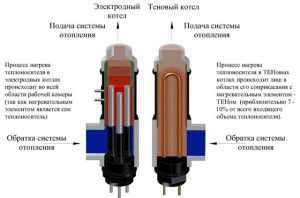

Electrode heating boilers

The most popular alternative to TEN heating boilers are currently electrode type devices. In them, the heat carrier is heated due to its own electrical resistance.

A design feature is the presence of an electrode (housing) and a cathode. The latter is located in the tank through which the coolant flows. When power is supplied, water splits into positive and negative ions, which tend to electrodes of the corresponding polarity. Due to the fact that alternating current is supplied with a frequency of 50 Hz, the polarity of the electrode changes. It is this phenomenon that provokes the heating of water.

The electrode electric boiler for heating a house is selected only for water. Before that, she must be trained to increase resistivity. It is best to purchase a ready-made coolant. If this is not possible, salt can be added to distilled water.

You should also take into account such features of mini electric boilers for heat supply of the electrode type:

- Gradual output at rated power. The best option is to invite specialists for the initial setup of equipment;

- Gradual dissolution of the electrodes. After 10-15 years of operation, a decrease in their diameter will reach a critical value. After this, a planned replacement of the electrodes is necessary;

- Lack of scale. This is due to vibration of the electrodes with a frequency of 50 Hz. There is no extraneous noise.

Another advantage is the possibility of choosing an electrode electric boiler for heating and hot water.In this case, the design will have two separate chambers, in each of which water is heated for heat supply and DHW.

In the absence of a coolant in the heating chamber in the electrode boiler, the surface will not overheat. This is one of the advantages of this type of heating equipment.

Rules for connecting an electric boiler to heating

In order to embed the electric boiler into the heating system, you should familiarize yourself with the safety rules. A complete set of factory heating equipment should include detailed instructions for the implementation of this event. It is she who is the main guide for connecting the boiler to heating.

First of all, you need to prepare the wiring. After connecting the electric boiler to the heating system, overloads in the network should not occur. For devices up to 9 kW, a 220 V network can be used. If the power is greater, a 380 V power supply should be connected. Experts recommend a separate power line from the distribution panel to the boiler.

Important is the choice of installation location. Before embedding an electric boiler in a heat supply system, it is necessary to think about its location in advance. The minimum distance from the wall should be 5 cm, from the floor - 50 cm (for suspended models), from the ceiling - 80 cm.

The procedure for connecting an electric boiler.

- Preparation of the wiring; if necessary, it is replaced with a new one with a large cross section.

- Pre-installation of the boiler, connection to the pipes of the heating system, leak test.

- Electrical connection. Pre-installed RCD.

- Filling the system with coolant. After that, pressure testing and removal of air jams is carried out.

- Test run of the boiler, its check in several operating modes, if such are provided for by the design.

It is imperative to provide for the installation of all necessary elements of heat supply - safety groups, valves, temperature and pressure sensors.

Electric boilers up to 3 kW can be connected to an electrical outlet. But even in this case, the permissible load on the wiring should not be lower than the maximum power of the equipment.

Making homemade electric boilers for heating is not recommended. Even a small error can lead to electric shock. One of the alternative options is the installation of heating elements with temperature controllers in the heating batteries. Thus, it is possible to make an electric convector from a conventional aluminum or bimetallic radiator.

The video material clearly shows how to choose the right electric boiler for heating: