If it is not possible to install gas or electricity heating in your home, you should pay attention to equipment that uses solid raw materials as fuel. Stropuva boiler can perfectly perform heating functions, and at the same time is convenient, since it requires only periodic laying of combustible materials in the furnace. The interval between fillings is once every 12 hours or less, depending on the type of materials burned and the design of the circuit.

How the device works

The principle of operation of the heating equipment Stropuva is based on the combustion of fuel in its upper part. This effect is achieved by supplying oxygen to the top layer of wood waste, coal or briquettes. As it burns, the hearth moves to the bottom of the furnace until all material is complete.

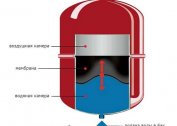

The efficiency and high efficiency of the equipment is due to slow combustion and decay, in which almost all the thermal energy is used to heat the water in the circuit. Due to the fact that the flame in the furnace is not intense, in most cases it is impossible to overheat and boil the coolant, therefore, in a heating system of this kind, an expansion tank can not be used.

If firewood is used as fuel, on average, their supply in the combustion bunker needs to be replenished once every 30 hours. With a more powerful energy carrier - coal - it is enough to lay the firebox once every five days.

How is the Stropuv boiler

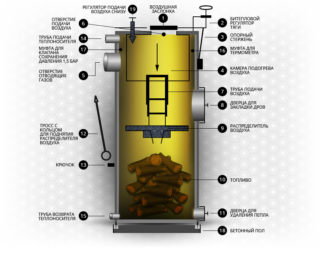

Stropuva boiler has an original design, which is built on the following elements:

- Case with a water jacket. This is the supporting part of the apparatus, equipped with a double wall with an internal space filled with coolant. Bottom and top of such a tank there are supply and return pipes.

- Fuel tank. A cylindrical-shaped container where firewood or other combustible material is laid. Two shafts with doors lead into it: one for supplying wood, one for removing ash, and also a smoke removal channel.

- Heated air chamber. It is necessary that the oxygen coming from the street to the area of fire burning does not reduce the temperature set and does not cool the heat exchanger.

- Oxygen distributor The element is made in the form of a nozzle with stops, in the middle of which there is an opening connected to the air heating chamber using a telescopic pipe. The control of the distributor is carried out by means of a ring and a cable.

- Manual air damper. It serves to reduce, increase the flow of oxygen into the combustion chamber.

- Thermometer and pressure relief sensor.

The solid fuel boiler of long burning Stropuva is installed on a concrete base having a strictly horizontal position.

Types of boilers

Stropuva equipment, like other types of solid fuel devices, the manufacturer produces different capacities. In addition, there are simpler models that work on wood and waste of this material, but there are more universal ones. The combustion chamber of the latter allows you to burn coal of different grades in it (except used in blast furnaces), as well as various fuel briquettes and pellets.

Solid fuel burners ordinary burning

Devices work only on wood and wood waste. Technical characteristics of the medium power unit:

- The return of thermal energy is 10 kilowatts.

- The recommended area for heating is not more than 100 squares.

- The coefficient of performance is about 87%.

- The volume of the water shirt is 34 liters.

- The capacity of the firewood bunker is about 25 kg.

- The size of logs in length is not more than 0.35 meters.

- Parameters of the firebox - 0.350X0.210X0.250 meters.

- Mass and size indicators - 1.92 meters high, 0.45 meters diameter, 185 kilograms.

Original device models are produced in the Republic of Lithuania.

Coppers of long burning Stropuva universal

These units are floor-mounted and can run on different fuels of natural origin: wood materials, coal, peat and briquettes. The models are equipped with a forced air blower and a capacious combustion chamber, which allows for the laying of fuel for a long time. Technical characteristics of high power equipment:

- The heat transfer power is 20 kilowatts.

- Heated space - 200 squares.

- Efficiency - within 85%.

- Heat exchanger capacity - 45 liters.

- The volume of the coal bunker is 130 kilograms.

- Mass and size parameters - 2.1 meters high, 0.56 meters diameter, 246 kilograms.

Due to its compactness, the device can be placed in a small furnace.

Advantages and disadvantages

The advantages of such models of heat generators include:

- High efficiency of about 87%.

- Long action on one tab and the absence of excessive heat, leading to boiling water in the system.

- The frequency of cleaning the ash pan is 3-1 times a month.

- The wood version of the equipment is completely non-volatile, it is controlled by a bimetallic plate. Universal models require an electric current of only 20 watts.

- The height of the chimney pipe for such devices can be from 4.5 meters.

- The equipment is safe, at critical temperatures, the structure is compressed, not an explosion.

In practice, Stropuv's devices have been serving confidently for over 10 years.

Disadvantages of the boiler Stropuva:

- The duration of combustion of the unit specified by the manufacturer on a different type of fuel is possible only under certain conditions. This includes good insulation of the house and a properly assembled heating system, and this is rarely seen in practice.

- You can’t throw firewood into the firebox during combustion - you need to wait until everything burns out, as a result, the effect of cold batteries is always observed.

- The bimetallic regulator does not allow you to precisely adjust the temperature in the system.

The unit is considered non-volatile, but the system to which it is connected requires forced circulation by the pump.

Experts recommend not adhering to the rule of 1 kilowatt of thermal energy per 10 squares of a room, but taking top-burning boilers is twice as powerful from the design option. This approach is guaranteed to provide greater efficiency of the device and the passport duration of work on one tab.

System binding

When tying the device, in addition to conventional heating radiators, a safety battery must be included in the system, on which you do not need to put the thermostat. This convector should be inserted first on the shirt feed pipe through the balancing valve and mounted so that the coolant can move by gravity in it in case of a power outage.

All other radiators go in a different circuit through conventional valves and return to the circulating pump. The pump itself is shunted through a three-way valve, which is connected by a second channel to the return pipe of the unit and is controlled by a temperature sensor mounted on the battery return pipe.

Among the most popular models of solid fuel boilers Stropuva, one can distinguish the wood-burning unit Stropuva 10S and the universal device Stropuva 20U, for 10 and 20 kilowatts of power, respectively, designed for heating suburban cottages.