Steam heating is considered one of the most dangerous, but continues to be used in various conditions. Its performance has been proven by many years of operating experience. Heating equipment differs due to different wiring options.

How steam heating works

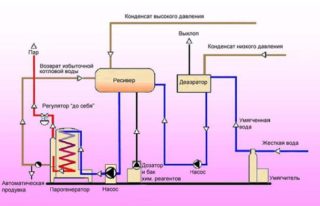

Many confuse steam heating systems with water. In fact, these are two completely different in design devices. The principle of operation of steam heating consists of several stages.

- In the existing device (boiler), fuel is supplied.

- Under the influence of combustion, the pipes with water inside are heated.

- When they are heated, water moves up and enters the expansion tank.

- From this comes the release of steam, which is transported to the coolant due to which the rooms are heated.

- In the process of burning fuel, all waste is discharged into the chimney, which is installed in the wall or goes to the roof.

Steam boilers with this principle of operation are unsafe, since there is a high risk of burns during contact with parts of devices. The temperature of the coolant reaches 100 degrees.

Advantages and disadvantages

Steam heating can only be used in exceptional cases. In this case, you need to consider some of the pros and cons of equipment. The positive qualities include:

- Efficiency and efficiency of heat transfer. A few minutes after the device is started, the room is heated.

- The system is able to give an efficiency of more than 2300 kJ when steam is generated, while an ordinary water boiler when cooling only 100 kJ.

- It does not require the arrangement of special radiators: you can do it with the help of several tubes.

There are more cons, and they are quite serious.

- Equipment is prohibited for use in public buildings and apartment buildings. This is due to the risk of explosion if mistreated.

- Due to the rapid heating, too warm air circulates in the room, which destroys all moisture and raises dust.

- Elements of the system are heated to critical temperatures; therefore, they are considered to be hazardous and require special decoration.

- Not suitable for all types of indoor decoration. Most modern building materials are easy to deform under the influence of high temperatures.

- There is no possibility to regulate heat transfer. To make the room a comfortable temperature, it is necessary to further equip the heating branches and turn them on as needed.

- During steam heating, a loud noise is generated that is unbearable for home use.

- There are constant temperature fluctuations in the room, as the system is equipped with automation, which disables the working mechanism as it warms up.

Be careful when operating steam radiators. Any contact with cold water can cause a depressurization of the system (metal will burst).

Where applicable

The scope of this heating option is quite narrow. Such units are permissible for operation in production halls, private homes, subject to safety precautions.

Steam heating in a private house will be appropriate if it is used for a short time, as it dries the air too much. In winter, such equipment can be left unattended.The system has a minimal amount of water, so the risk of explosion and depressurization is not great.

Wiring types

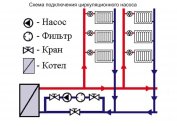

The steam type of heating can be divorced in the room in several ways. Each of them has its own characteristics.

- Top. It implies the placement of a steam outlet under the ceiling. Pipes go down to the radiators. Usually, they try to use this type of system for efficient heating, since here steam moves along one carrier and condensate moves along another.

- Lower. The condenser and steam are moving along the same pipes. As a result, water hammer and depressurization of the system may occur. The pipes are located at floor level.

- Intermediate. A steam outlet is laid at the window sill level, so the hot pipes are in the access zone. Because of this, the risk of burns increases. The principle of operation of this design is similar to the upper wiring option.

Regardless of the method of diluting coolants, all pipes transporting steam must be laid down at a slope of 1-2 degrees.

Organization of steam heating

Steam heating has a different fuel source. It can be natural gas, liquid or solid fuel. Before arranging, it is advisable to choose the right heater and its accessories.

Boiler selection

With a variety of equipment are determined by the area of the room. The larger the building in need of heating, the more powerful the boiler should be.

- For rooms up to 200 sq.m - 25 kW;

- Buildings from 200 to 300 sq.m - 30 kW

- For premises with an area of 300-600 sq.m - 35-60 kW.

Traditionally, 1 kW of power per 10 sq.m. is used in the calculation. This rule is optimal if the room has a ceiling height of at least 2.5-2.7 m. When buying heating equipment, be sure to ask the seller for a certificate.

Pipes

Among a large assortment of pipes for the arrangement of steam heating, only metal options are used. They do not deform when exposed to heat. Among them, budget steel is predominant. However, with strong humidity, corrosion quickly forms on the surface.

It is allowed to use galvanized or copper pipes. The latter are expensive, require soldering for a tight connection, while being considered the most reliable. They much more efficiently transfer thermal energy to the room. At the same time they are very hot.

Life time

The life expectancy of steam heating depends on compliance with safety requirements. Usually, with the correct setup and sealing of the system, the design has served for more than a dozen years. However, with pressure surges inside the pipes, malfunctions in the operation of the boiler and its components are possible.

Using steel pipes for the heater, it is worth remembering that they will not last long. Hot and humid steam will circulate in the carrier. These are optimal conditions for the development of corrosion and the appearance of rust. Often such a problem occurs at the seams.

General installation recommendations

Many face errors or dysfunction of heating after it is organized. Therefore, it is important to consider some tips. They will help to eliminate various troubles.

- Plastic pipes are not suitable for soldering due to the high temperature of the coolant.

- Each stage of the installation should be carried out by specialists or at least controlled by them. One wrong step and the system can fail, cause damage to property and health.

- Be sure to take into account the amount of steam produced (prescribed on the package). The heating rate of the room depends on this.

Steam heating systems are considered efficient and easy to operate. In order for the device to work correctly, it is necessary to comply with safety requirements, and also remember to service it regularly.