A gas boiler with a closed combustion chamber is considered one of the most convenient options, since it requires minimal control from the owner during daily operation. Before installation, it is useful to study the principle of its operation and design, the main advantages and disadvantages, operating rules, as well as the features of its types available on the market.

The principle of operation of a gas appliance with a closed chamber

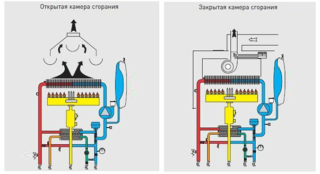

Open and closed gas boilers have differences regarding the basic principles of their operation. In a closed unit, the combustion chamber does not have access to open oxygen, it is equipped with only two openings: for a chimney and air intake. The air intake element can be part of the chimney or installed as a separate pipe. The chimney allows you to remove the exhaust gas and vapors, the air element passes fresh air.

In most models of closed boilers, there is a fan that creates additional noise. For some buyers, this factor is critical.

Advantages and disadvantages

Boilers of this type have many advantages. They are most often chosen by the owners of small apartments and houses, since there is no need to allocate a separate room. The list of advantages include:

- compactness and esthetic appearance;

- lack of problems during installation and during operation;

- no need to install a vertical chimney and additional equipment for ventilation;

- high efficiency combined with economical fuel consumption.

Devices in this category have only one drawback - the dependence on electricity, since the burner and ventilation elements work from it. If the network suddenly shuts down, the house or apartment will remain without heating. To prevent the problem, you can additionally purchase a wood stove, fireplace or gasoline generator.

Chimney and heat exchanger

For a boiler with a closed combustion chamber to function fully, he will need a coaxial type chimney. It includes pipes of various diameters that are inserted into each other. Through a large pipe, air goes to the boiler from the side of the street, with the help of a pipe with a small diameter, the gas comes out and is immediately cooled.

Thanks to modern engineering solutions for units of this type, there is no need to install additional ventilation. Combustion products do not affect the atmosphere, since the fuel burns completely.

Heat exchangers belong to the main parts of heating units, as they transfer energy to the heat carrier from burnt fuel. They are divided into three types, taking into account the material of manufacture and are steel, copper or cast iron. Options made of steel are inexpensive, but rust quickly, copper counterparts are considered more durable. Cast iron is no less durable than copper, but cracks often form on them during operation.

A variety of gas boilers with a closed chamber

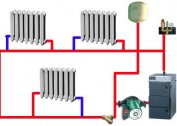

Gas boilers with a closed chamber for heating are single-circuit or double-circuit. Single-circuit are intended for heating the house, dual-circuit in addition to this function are also used to heat water. Single-circuit models are cheaper; if necessary, you can buy additional parts and a boiler for them.But in such a situation, the total price of the unit will significantly exceed the price of a standard dual-circuit analog.

Single-circuit

Single-circuit devices have virtually no disadvantages, they are completely independent of the pressure of the water supply and provide an uninterrupted supply of hot water. Also, for them there are no limits on the amount of water used in each of the installed taps.

Bypass

A dual-circuit unit is cheaper when compared with a single-circuit analog and its additional equipment. It has compact dimensions, takes up a minimum of space, does not require much effort during installation. This is a fairly economical option, since the device heats only a certain amount of water.

Of the minuses, the owners of such units note problems with the temperature of hot water, which is affected by the pressure of the water pipes. The temperature will drop when several taps are opened at once, if they are too far from the boiler, it will take longer to wait for the water to heat up. This drawback is absent in double-circuit units with storage tanks with a volume of up to 60 liters or boilers with layer-by-layer heating. Water is supplied there at the same temperature.

Floor boilers

Floor-standing appliances require a special room, as they differ in large dimensions and increased power, when compared with wall-mounted ones. The list of their advantages includes cast-iron heat exchangers, whose service life is up to thirty years. They do not need a chimney with a large draft.

There are also disadvantages - floor-standing boilers take up space on the floor, because they cannot be hung on the wall due to their weight and dimensions. For this device, you need an expansion tank and the creation of strapping drive.

Wall mounted boilers

Wall-mounted appliances are most often used in urban rooms and small cottages due to their compact dimensions and convenience. They do not cause difficulties in the installation and maintenance process.

Boiler operation without power supply

Boilers with closed chambers can operate without electricity, but for this purpose they will need additional equipment. Choosing it is depending on the needs and type of specific device.

Electric generator

A gasoline or diesel electricity generator eliminates a power problem if the house does not have a power source. For boilers of foreign production standard generators are not suitable. For such a device, it is necessary to purchase a stabilizer that converts the voltage into the desired type of sinusoidal shape while observing stable standard values.

Uninterruptible power supply

Uninterruptible power supplies or UPSs also help eliminate the problem in the absence of electrical energy for combustion. They do not need so much power to ignite the flame of the burner and turn on the fan. This is a more economical method compared to a generator, so it is used if the network is completely free of voltage. UPSs have many advantages, including the absence of noise during operation and problems when connecting, ensuring autonomy, the absence of maintenance costs and consumables.

UPSs made using dual converter technology can produce a full sine in battery mode and from the mains voltage. To select the capacity of a non-volatile battery for them, you need to take into account the time during which the UPS will need to maintain the boiler in operation.

Since the power of standard boilers varies between 50-300 watts, the current should be no more than 70-400 volt-amperes with an acceptable difference.