Water devices for floor heating differ from electrical units in the principle of operation of the coolant. The main role in the design of the water system is played by the collector. The distribution unit ensures the efficient operation of the equipment in the house.

The need to install a collector for underfloor heating

The main function of the collector is mixing the coolant and subsequent distribution along the heating circuits. The principle of operation is based on the entry of heated water into the structure, where it is mixed with cold water. Then it is redistributed for subsequent circulation. The mixing level of cold and hot liquid is controlled by valves.

The collector provides:

- long term of operation and safety of use of the heating system;

- reduced risk of burns and other injuries;

- saving gas and electricity.

The coolant is heated to 75–90 ° C. This is an optimal indicator for radiators, but an unacceptable value for a warm floor. If water of this temperature enters the pipes, the person in the room will feel uncomfortable. In addition, the flooring may be deformed. For these reasons, manifold installation is shown.

The device equalizes the temperature of the direct and return flows, regulates the performance of the heating system by means of sensors, and also ensures uniform heating of the pipes.

Collector device

Warm water floor - an independent heating system, which involves a connection to the main. For this purpose, collectors are used.

The simplest design of the device includes a segment of pipe to which other pipes are connected. One end of the distribution unit is connected to the pressure piece. Water pipes are connected to additional leads. Unified constructions are rarely mounted. They were replaced by devices with a complex configuration.

The purpose of the two-way model is to regulate the supply of hot water to the cold circuit of a warm floor. The function is provided by the thermal head, which closes the valve with an increase in temperature, and opens with a decrease. The valve is installed when heating an area of 190-200 square meters, when the installation of radiators in the room is not expected.

The advantage of the model is the presence of a supply valve, which eliminates temperature surges in the heating system.

The three-way device is universal. It is included in complex heating systems with a large number of heating circuits. The unit is used to heat a room of 250 square meters.

The disadvantage of three-way valves is sharp temperature drops when a large volume of hot water enters the circuit. To eliminate this effect, the collector is supplemented by servos and weather sensors.

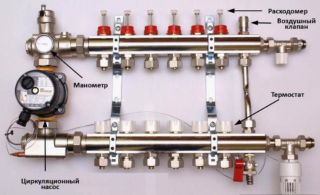

Manifold Parts

The collector includes various structural elements, each of which performs a specific function. The inclusion of one or another part in the device is limited and depends on the general technical parameters of the heating system.

A modern distribution unit contains a large number of elements, among which should be noted:

- Circulation pump.It provides the heating system with the right pressure. The circulation of hot water is carried out in full, which increases the efficiency of the floor heating system.

- Mixing unit. This is the regulator by which the system is fed with hot water. The operation of the unit is automated: changes in the coolant parameters are recorded, after which the valve automatically opens and remains in this form until the water temperature rises to the required value. A servo drive acts as a thermostat.

- Distribution comb. It is a node with a large number of taps for connecting water. Flow meters are mounted on the comb, which distribute hot water to different parts of the circuit.

- Weather sensor. The device controls the flow of hot coolant and provides uniform floor heating.

In expensive models, representing the finished collector system, there is an air vent. The main function of the element is to remove accumulation of excess air.

Purpose and installation features

Correct installation requires an even flow of hot water to the circuits. The operation of each component of heating should not depend on the level of the indicator on other devices.

When choosing collectors, the number of circuits that are connected to the heating is taken into account. The system will only work if there are enough conclusions. The assembly includes stop valves for each outlet. Valves provide accurate flow rate.

The device is mounted in a special cabinet 12 cm thick. All additional elements: monometers and air vents must be placed in the box. There should also be enough space for floor heating pipes. The nodes are located above the circuits of the heating system.

Pipes from the manifold go down. This eliminates air congestion.

Homemade designs

To assemble a home-made unit, the design of the heating system should be clearly presented. It is necessary to familiarize yourself with the principle of functioning of the collectors and their main purpose. It is also necessary to conduct a competent calculation.

Before making the device with your own hands, you need:

- determine the performance of warm floor branches;

- calculate performance indicators, coolant flow rate and location of fragments;

- indicate the presence of other heating appliances that will be connected to the distribution node;

- choose a system of control and regulation;

- indicate the location of the collector.

It is important to pay attention to the selection of components. They must be designed to function in similar heating systems.

The diameter of the distribution manifold is chosen so that its cross-sectional area is the same with the cross-sectional area of the pipes.

Assembly of purchased parts

The assembly of the distribution unit for the warm floor from the purchased parts is not difficult. Step-by-step instructions are included with each product kit. It contains a drawing.

The coolant tubes are equipped with factory valves and flow sensors. They should be connected if the collector is presented in sections with two or three branches.

For ease of assembly, it is advisable to fix the tubes using brackets. Then, plugs, connection elements, valves for constipation and control devices are mounted. The next step is to mount the unit to the wall and install the circulation pump and valve. Carrying out the installation in the reverse order is not recommended, as it will be difficult to mount the assembly.

The pump and valve with a thermal head or servomotor are mounted on the basis of a given scheme, after which the heating pipes coming from the boiler are connected to them, and the pipes of the heating circuits are connected to the outlets.

Replacing some parts

The factory device is of high cost. This explains the attempt to collect a collector of underfloor heating with your own hands. It is impossible to make all components. Some factory items will have to be purchased. When using polypropylene, all parts are soldered taking into account tightness. You should monitor the position of the nozzles for ease of connection.

An easy way to assemble the distribution unit is to solder the device from polypropylene pipes and fittings. The required pipe cross section is 2-3 cm. Tees and bends of the same diameter will also be required. The number of fittings, valves and circuits of the heating system must be the same.

First, pipe fragments are measured and cut. The distance between the tees should be small. Then valves, adapters and fittings are welded to the tees to connect to the pump.

The collector for underfloor heating with its own hands has disadvantages: there is no thermostatic valve and flow sensor on the supply pipe. The system is manually adjusted.

It is advisable to assemble the collector with the replacement of factory parts for the simplest schemes of the heating system. Complex equipment is recommended to be purchased in specialized stores.