Over time, cast-iron radiators lose their thermal power, since the entire inner surface of the battery is contaminated with impurities that arrived with the coolant. At the end of the heating season, a large amount of plaque remains inside the sections, which leads to the destruction of gaskets.

Preparatory work

Before proceeding with the work, you need to prepare all the necessary working equipment:

- pipe wrench No. 3 to unscrew the futurki and locknuts;

- metal brush;

- grinder or pipe cutter;

- sledgehammer and hammer;

- a piece of chalk;

- inch pipe from 50 to 100 cm long.

- hacksaw for metal.

It is important to pre-prepare the site where it will be convenient to disassemble the radiators. The best option is a durable wooden shield. Radiators are laid horizontally on the surface and get to work.

The most favorable time for work is summer, when the heating system is turned off. Before starting to disassemble the radiator into sections, it is important to drain the entire coolant from the heating circuit. To do this, turn off the locknuts that are on the connections to the radiators. Next, turn off the foots, after which the battery can be removed.

DIY battery disassembly

To disassemble a cast-iron heating battery into sections, as follows:

- It is necessary to find out in which direction the blind plugs are unscrewed, and on the key, note the length of the unscrewed nipple. To do this, put the key on the radiator, bring the edge to the point where the sleeve is. On the key with chalk in a circle, a mark is made to which the tool is inserted into the radiator.

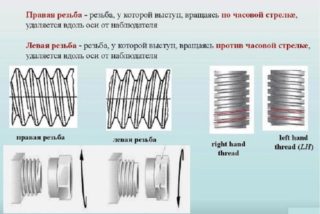

- It is important to figure out which way you need to turn the key for cast-iron radiators. The thread can be left and right. The direction of rotation is determined by the foot, which is screwed on the same side as the key.

- If the thread is right, the foot should be screwed in clockwise, therefore, when untwisting, the direction of the key should be directed in the opposite direction. Left-handed is the opposite.

- The promotion of the battery begins with the first section. It is necessary to carefully “tear” the thread on both nipples. In most cases, half the key is enough. Next, the radiators are unwound in sections on each side so that the interval between them is 0.5 cm.

- When spinning the heater, it is important to observe the specified gap between the sections, if you neglect this rule, the thread may seize. When they begin to unwind the radiator, it is recommended to put the key on the pipe, this will allow you to apply less effort when disassembling.

By this algorithm, all modern cast-iron batteries are disassembled. As a rule, such radiators are additionally equipped with plugs with the corresponding marking.

Dismantling an old cast-iron battery

If you have to disassemble an old cast-iron battery, some difficulties may arise. If the thread is stuck, it must be thoroughly warmed up before disassembling using an autogen or blowtorch. When the joints are well warmed up enough, you need to quickly break the nipples at the same time on both sides. By a similar principle, other attached radiator elements are twisted out.

After prolonged use, the metal can thoroughly rust. For drastic measures, a grinder and / or hacksaw may be required.Unscrew the remains of the nipples from their seats without fail, using a brush to clean the thread.

Sometimes the application of the described methods does not have the desired effect. The only solution to this problem is to break the radiator with a sledgehammer. Previously, the battery is removed from the mount, placed on a flat horizontal surface and beat on the axial part of the section until it falls off.

Installing a cast iron battery

In order for the work to be carried out efficiently and the batteries lasted for many years, you must adhere to the following sequence of actions:

- The heating circuit must be turned off, and stop the flow of coolant into the apartment.

- A new radiator is hung on the brackets with a check by the construction level of its horizontal and vertical position.

- Plugs are unscrewed from the heater.

- If the lateral connection scheme is applied to a single pipe circuit, the bypass with the valve is pre-mounted and connected. If the heating system is two-pipe, cranes are used.

Before proceeding with installation work, it is recommended to verify the proper assembly quality of the sections and adjust each nipple. After this, the sections are assembled together, the structure is crimped to check the quality of the connection. If no leaks are detected, the structure can be connected directly to the circuit.

After connecting all heating segments, you need to make sure that the work is done efficiently. To do this, water is launched into the pipes under pressure. If there are no leaks, strange knocks and noises, radiators are connected correctly.

Cleaning cast iron radiators

For cast iron batteries to last for decades, you need to clean them regularly. Cleaning must be done before disassembling the battery. It is important to consider that the construction is heavy, it is better to perform work with a partner. You can flush the radiators in the courtyard or in the private bathroom.

It is recommended to use the following tools:

- water air gun;

- soda ash;

- means for washing a car radiator;

- milk serum.

Car cleaning is as follows:

- Two openings on one section are reliably muffled.

- The product is made of cast iron.

- Next pour hot water.

- The other two openings are also drowned out, the structure is placed on the floor and they wait at least two hours.

- At intervals of 10-15 minutes, one edge of the battery is lifted so that the product is evenly distributed over the entire surface.

Finally, the radiator cavity is washed well with clean running water.

Disassembling a cast-iron battery, if you follow all the recommendations, is easy. If you have doubts about the quality of performance, it is better to invite a qualified specialist.