At the output of any heating system, a water carrier of a fixed temperature circulates, which is automatically maintained within specified limits. In some of them there are several circuits with coolants heated to different levels. For their mixing and obtaining an aqueous medium with the required temperature, special devices called heat mixers are installed in the structures of the warm floor.

Purpose of the thermal valve

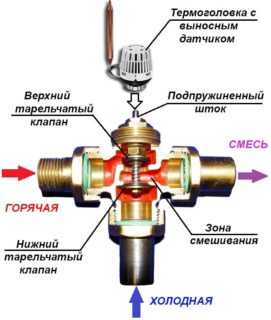

The thermostatic valve for underfloor heating is a regulating device of a special design that is built into pipelines with a working fluid circulating through them. Unlike a two-way device, it is designed to mix two streams (cooled and hot) and obtain a third one with a fixed temperature at the output. The presence of such a three-way valve in the system allows us to solve the following problems:

- change the direction of water flows;

- mix them in a certain proportion;

- to receive water with a constant temperature at the outlet of the heating system.

To expand the range of tasks solved by these devices, thermal mixing valves of various types with specific characteristics are used.

Types of valves according to the method of mixing

Mixers for underfloor heating have several varieties that differ in their functions. The first is a thermostatic valve with a special sensitive sensor head located in each of the circuits and responsive to the temperature of the environment. The principle of operation of the thermostatic element is based on determining the temperature difference and issuing a command to the actuator that controls the flows of warm and cooled water.

In systems of the second type, a valve with a thermostat function is used as a sensitive and control element, which allows maintaining the temperature in the floor heating system at a fixed level. It works like all master devices and provides a more precise adjustment of the monitored parameter.

Advanced temperature controllers use an integrated controller to control flows. This option of organizing the regulatory process is the most accurate and most in demand among the consumer.

Types of valves in the direction of flow

Two schemes of mixing devices are known that respond to the direction of flows in the underfloor heating system. They are represented by symmetric and asymmetric varieties of valve mechanisms. The choice of a particular control scheme depends on the type of heating system and the convenience of its installation in specific operating conditions. In a symmetrical mechanism, water flows from different ends of the valve, and its mixing occurs in the middle part of the device body. Thanks to this design, the valve has a small size.

Two schemes of mixing devices are known that respond to the direction of flows in the underfloor heating system. They are represented by symmetric and asymmetric varieties of valve mechanisms. The choice of a particular control scheme depends on the type of heating system and the convenience of its installation in specific operating conditions. In a symmetrical mechanism, water flows from different ends of the valve, and its mixing occurs in the middle part of the device body. Thanks to this design, the valve has a small size.

In an asymmetric valve, flows of cold and hot water come from one of the ends and from below, respectively. The resulting aqueous mixture is fed into the system from the second end of the valve. This scheme is also widespread, due to the versatility and ease of maintenance of the valve mechanism.

Other types of industrial devices

The domestic industry produces many temperature controllers for the water floor, which allows you to control the flow of fluid in an autonomous mode. Among the known varieties of valve mechanisms, the following types are distinguished:

- mechanical three-way valves for underfloor heating;

- the same models, but with a remote sensor;

- sensor mixers;

- electronic devices;

- programmable temperature controllers.

Mechanical devices are the simplest, cheapest and most reliable devices in operation, equipped with a protective casing made of durable plastic. To adjust the temperature with such a device, it is enough to turn the thermostatic head in the right direction. The exact value from the temperature range is selected by turning a special disk having a scaled division.

Mechanical thermostats equipped with an external temperature sensor are more advanced designs that allow you to control the value of the operating parameter. Their disadvantages include the need for continuous monitoring of the current parameter, which can be changed only in manual mode. This forces specialists to install an additional thermometer in the system (especially for temperature control). Given the difference in the settings and readings of the device, it is possible to manually adjust this indicator with an acceptable error.

When operating sensor mixers connected to the system through special adapters, the thermal parameters are set from the remote panel. In some models, a manually controlled remote control is used for these purposes. This type of temperature controllers belongs to more modern models, greatly simplifying the temperature control procedure. They provide several adjustment parameters, which ensures accurate setting of the desired temperature. The reliability and safety of using these devices largely depends on the specific model, when choosing which they are faced with a wide range of price categories. In this situation, it is undesirable to save and choose a cheaper model, since real losses will exceed the difference in the spent funds.

Electronic models of temperature regulators in their functionality are practically inferior in no way to similar sensory samples. On the body of these products there is a small display and a set of buttons by which the user can easily program the desired mode of functioning of the warm floor. In the most advanced samples, it is possible to introduce a program designed for the coming week and for individual periods of the current day.

Wireless devices allow you to maintain the temperature in an apartment or in a private house only if people are present in them. At other intervals, the floor system is put into standby mode. Due to this, the costs of heating the premises during the heating period are reduced. Such devices can be connected to the smart home control system, when working with which heat savings reach 30 percent. Due to the fact that you can manually control the modes (at the moments of the user's presence in the house), the indicator for economy will be even greater.

A feature of programmable devices is the ability to simultaneously control several water heating systems located in different rooms. Their disadvantages include:

- high cost of equipment;

- difficulty setting

- the need to call the specialists of the service center during the start-up work.

In addition, the user will have to study the attached instructions and in the future be guided by its instructions.

Radio-controlled models used to adjust the temperature of the medium are rarely used, due to their unreasonably high price. In terms of their functionality, they practically do not differ from those already described, and the price increases several times. The only difference is that the mechanisms are controlled not through the cable, but through radio signals. During the operation of such a system, the thermostat receives signals with information about the indicators of the sensors and transmits them to the controller.The latter processes the package and sends the radio signals to the servos of hot or cold water.

The disadvantages of these systems include the need to equip transmitters and receivers of each of the individual devices. The complication of process control circuits leads to frequent breakdowns of electronic components and to difficulties with the restoration of devices.