Heating boilers allow you to create comfortable conditions in the house. The equipment from Lemax is gaining more and more popularity every year. Products are of high quality and reliability, as well as a wide selection of models for any operating conditions.

About company

The Russian brand Lemax was formed in 1992 in Taganrog. During its existence, the company has gone from a small company to a large manufacturer of heaters. Production is at the highest level, therefore, the products have reliable characteristics that allow it to compete with other brands. Lemax boilers are attractive to consumers for their price / quality ratio.

Products are used in country houses, dachas, cottages, city apartments in the absence of a stable heat supply.

The device boilers Lemax

The device has the following components:

- Gas burner unit. It consists of a burner, wick, piezo ignition. By pressing the button, the piezoelectric element igniting the wick is activated. Then the burner lights up smoothly.

- Heat exchanger. Used to heat up the coolant.

- Automation. Includes control boards and sensors.

- Expansion tank.

- Circulation pump.

The layout of all parts is developed by Lemax.

Benefits

Judging by customer reviews, Lemax products evoke positive emotions due to performance, design and cost-effectiveness. The main positive aspects of solid fuel and gas boilers are:

- High efficiency reaching 92%.

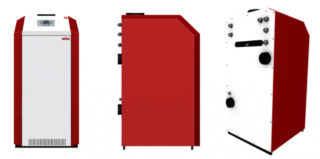

- Stylish appearance. The devices look good in modern interiors.

- Safe operation and inclusion due to multi-stage protection.

- Easy to connect and use. Easy to light the boiler on and off.

- Duration of work, reaching 25 years.

- Release of single and dual circuit devices.

The company manufactures floor and wall mounted heaters.

Varieties of Lemax boilers

Most of the products are floor boilers. They are in great demand among consumers and are bought for private homes because of their high power and reliability.

It is more convenient to install wall-mounted devices in the apartment. Their operating principle is based on the operation of the burner, which is built into the housing. She heats the heat exchanger. Circulation is natural or forced.

Gas floor heaters are available with the following types of heat exchangers:

- Of steel. The thickness is 2 mm.

- Made of cast iron with a thickness of 4 mm. It is considered the best heat exchanger for a single-circuit Lemax heating boiler.

Devices differ in power, functionality and control method.

Boiler installation and adjustment

In order for the Lemax boiler to function without problems and breakdowns, it is important to install and connect it correctly. The installation should be entrusted to professional workers, especially if the user does not have the skill to connect heating equipment.

The main installation requirement is the provision of intensive removal of combustion products. The manufacturer recommends connecting a draft device made of sandwich pipes to the chimney.

Launching and connecting is quick and easy. The factory settings are suitable for operation; they can be adjusted mechanically.

The gas valve plays an important role in the automation unit.This is a device that controls sensors or controllers that receive information from sensors. The product may consist of two valves - a conventional and an electromagnetic one. When you start the second opens by pressing the button to ignite the wick. Then the user can release the button. When the igniter is blown, the thermocouple cools down and the valve closes. The other spring valve closes after a signal from the draft and temperature sensor.

Common problems

When working with equipment, malfunctions can occur. The main types of malfunctions include:

- Problems with heating water. The device cannot dispense the required amount of liquid. To prevent this situation from happening, it is recommended to buy a single-circuit boiler and connect an indirect heating boiler to it separately.

- Spontaneous shutdown of a torch. Caused by problems with traction or damage to the temperature controller.

- The smell of gas. Leaks can occur due to poor gaskets in the joints. Their replacement is required.

- The appearance of a long red flame. Caused by insufficient draft or clogging of the burner.

- Cooling the battery when the boiler is hot. Little coolant or incorrect installation.

The main problems associated with the equipment are listed. You can fix them yourself. Complex failures need to be trusted only by specialists.

In case of problems with the traction sensor, you need to replace it with a new one. The item can be bought at any specialized store. If the problem is with the pilot light, you need to reconfigure it. Information on adjustment can be found in the instructions.

Browse Popular Models

The manufacturer offers several series of gas boilers: Patriot, Leader, Wise, Prime-V and Wester Clever. All devices have Russified control.

The Wester Clever range is represented by four atmospheric convection boilers with different power values. For example, the Wester Clever 30 has an efficiency that reaches 90% and a heating power of 34 kW. The Wester Clever 40 model has a large throughput and a heating capacity of 45 kW.

The premium line is installed in rooms equipped with a chimney. Power range from 8 to 100 kW. There are modifications with one and two circuits. Both connection methods are available - left and right. There is an automatic flame intensity control. The heat exchanger is treated with anti-corrosion treatment. An example is a single-circuit boiler of atmospheric type Premium 16 with an efficiency of 90%. The gas boiler Lemax Premium 16 has a capacity of 16 kW and is able to warm up an area of up to 160 sq.m. The lineup has an upgraded version of Premium Nova with automation that supports the parameters set. There is an adjustment of the coolant pressure.

Patriot is suitable for installation with any type of ventilation (natural or forced). There are parapet and wall versions for installation in the apartment. Combustion products are discharged through a coaxial chimney. The average power is 6-20 kW.

Wise products are made of four millimeter Czech cast iron. They have an optimal ratio of the volume of water to the mass of the heat exchanger. Devices are stable at temperature and pressure surges. There is the possibility of transferring to liquefied fuel, connecting additional indirect heating tanks, thermostats, control systems. The average thermal performance is 16-60 kW.

The leader is also equipped with a cast-iron heat exchanger. The surface has silvering. In the lower part of the furnace there is an injection burner. They have only one circuit and are able to heat an area of 150 sq.m. up to 500 sq.m. Power is 19-55 kW. Relate to the most expensive products. The service life is 25 years.

Safety and operating rules

Each model is equipped with a security system, which includes the following elements:

- overheat protection;

- traction sensor;

- fire suppression protection;

- protection against soot and precipitation.

Wall mounted boilers are equipped with a safety valve and have frost protection.

For the correct operation of the equipment, the operating rules must be observed.

- Repair work must be carried out by a specialized organization. The owner of the boiler is only allowed to check and clean the chimney, repair the heating system.

- Most models can be used in facilities that are not characterized by hazardous conditions.

- Before turning the boiler into the chimney, it is important to make sure that it is not blocked. This affects the traction, the lack of which the device will not effectively heat the house.

- Service is provided by professional staff.

It is important that there is no aggressive dust and fumes in the room.