Against the background of constantly growing bills for electricity and heating, the issues of thermal insulation of buildings, premises and communications are becoming increasingly relevant. The most popular material in industrial and private construction is extruded polystyrene foam. The products are distinguished by excellent technical characteristics and a wide scope. On sale are models with different configurations, markings and costs. In order not to get lost in this variety and choose the right product, you should study all the features of extrusion polystyrene, from the stage of its manufacture to the finishing options after application to the base.

Production Technology and Composition

Extruded polystyrene is produced by foaming the heated polymer raw materials, followed by extrusion and cooling. The raw materials are granules of polystyrene plastic, the particles of which, under the influence of a solvent and a carbon catalyst, increase in volume, forming a foamy substance. In the process of cooling, the mass becomes denser and more viscous. At this point, it enters the extruder. During the passage through the molds, the material finally cools and takes on the final form. Next, it is cut into predetermined forms, packaging and transportation to the finished goods warehouse.

In finished form, extruded polystyrene is 99% air. The remaining volume is occupied by the walls of the capsules inside which it is enclosed. Unlike polystyrene, extruded polystyrene is a monolithic material with closed-type internal cells of 0.1-0.2 mm in size. Thanks to this composition, a number of insulating characteristics are achieved that similar materials with a different composition do not possess.

Insulation marking

Domestic manufacturers produce insulation extruded PPS that meets international quality standards. Part of the products is exported to neighboring countries. Based on this, the classification adopted in Europe is used for product labeling.

The material is indicated by the following symbols:

- XPS - extruded polystyrene foam;

- EN - European standard;

- T is the accuracy of the geometric parameters in mm;

- 25-45 - density in kg / m3;

- CS - foam compressive strength;

- DS (ТН) - indicator of thermal expansion in%;

- TR is the tensile strength.

Manufacturers Carbon, Prof, Xps and Technonikol mark their products with signs indicating additional characteristics of EPP:

- 35 - type;

- G — corrugated surface;

- S — edge selected quarter;

- N — edge spike — groove;

- 50 - thickness in mm.

Marking is applied to the packaging; some manufacturers make it on the material using an automated laser printer. This approach facilitates the monitoring of the performance of work by wage workers.

Release form

Plasticizers are added to the EPP insulation, so that the material acquires various properties. They are in demand in various sectors of construction activities, allowing you to solve the most complex engineering problems.

The consumer can purchase material of this form:

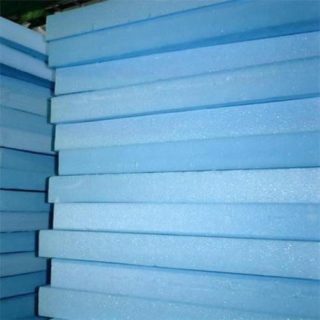

- Expanded polystyrene plates. Products are made in square and rectangular format. The thickness of the sheets is 25-150 mm. The standard dimensions of the plates are 600x1200 mm, 600x1250 mm, 600x2400 mm.In wall insulation of private buildings, the most popular layers are 50x100x100 cm in size with a selected edge. Plates are used for thermal insulation of objects with a smooth and strong external surface. The scope of use extends to the interior and exterior.

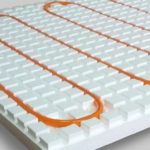

- Substrates. The material plays an important role in the insulation of the floor covering, in the soundproofing of rooms and in protecting them from moisture. The substrate is available in the form of plates and rolls with a width of 50 cm to 100 cm. Some brands have an accordion configuration, which when unfolded forms a monolithic surface without cracks and joints. The density of the flooring is high enough not to bend under vertical loads. Moreover, the material has elasticity and flexibility, which helps to compensate for small defects in the base. Corrugated top provides free air circulation, prevents the accumulation of moisture, the formation of mold and fungus.

- Decorative elements. Dense and lightweight material has found application in the manufacture of products used for finishing and decorating facades of houses, residential and office buildings; bagas, platbands, ceiling and corner plinths are made from PPP. After mounting on the surface, the polystyrene is coated with oil, acrylic or water-based paint.

Such widespread use of the material is justified by its unique properties.

- Expanded polystyrene for a heat-insulated floor

- Roll EPPS for floor

- Decorative elements

Characteristics of expanded polystyrene

Extruded polystyrene foam has the following specifications:

- operating temperature - from -70 to +100 degrees;

- thermal conductivity - 0.2776-0.0320 W / mS;

- compression density - 100-150x1000 KPa;

- vapor permeability - 0.009-0.013 Mg;

- combustibility class - G3-G4;

- moisture absorption - 0.2-0.4%;

- density - 25-45 kg / m3;

- melting points - 150-180 degrees.

Indicators vary depending on the brand of products, manufacturer and purpose of the material. Color, depending on the properties, is gray, blue and green.

Advantages and disadvantages

Due to the well-thought-out chemical composition, the decision to foam the mass and the polyurethane insulation used at the final stage of extrusion manufacturing, it has acquired many useful characteristics in the field of repair and construction.

Plates and rolls have the following advantages:

- Environmental Safety. Under normal operating conditions, the insulation itself does not emit substances harmful to humans into the environment.

- Low thermal conductivity. This indicator is the best among existing analogues. Only sprayed polyurethane foam can be compared with it, having a great price and difficulty in applying.

- Water resistant. Even being in damp soil, a good insulator reliably protects the object from moisture.

- Strength. The material is tough, it withstands high pressure, maintains its shape, does not break when dropped. At the same time, it is able to shrink, adjusting to surface irregularities.

- Easy installation. To install any of the types of insulation EPPS, a standard set of household tools and initial skills in dealing with them are enough.

- Durability. The estimated life is 50 years. However, the first samples made 70 years ago practically did not change.

- Resistant to mold and mildew. The material repels insects, birds and rodents.

- Low specific gravity. There is no additional load on the supporting structures and the need to strengthen the foundation.

- Affordable cost. People with limited means can afford to buy such material.

Polystyrene also has weaknesses. It is destroyed by ultraviolet radiation and contact with acetone-based adhesives.

When heated above 80 degrees, the polymer begins to emit harmful substances.Flammable plastic, ignition is accompanied by the formation of thick toxic smoke. As a heater, it is better to use it outside of buildings.

Fields of application

Due to its many advantages, extrusion PPP can be used in different climatic conditions.

The material is used in such areas of construction activity:

- Warming of residential buildings and engineering structures. It is used to equip the foundation, blind area, floor, walls, ceilings, attic and attic coatings.

- Thermal insulation of external and underground utilities. EPP is excellent for protection against cold water, sewer and heating systems.

- Preparatory work in the arrangement of roads, squares and runways.

- Decoration of buildings and structures. Polymeric products are used for finishing work in the repair and installation of interior decoration, suspension and tension structures, decoration of window and doorways.

- Internal filling of cooling equipment. Foam material is in demand for the manufacture of refrigerators, refrigerators, chests and freezers. On an industrial scale, polymer is used to insulate warehouses and storage facilities.

In comparison with analogues by the criterion of price-quality, PPP is considered the best universal insulation.

Mounting Methods

The following installation methods for extruded polystyrene foam exist:

- Plastering. It is applied in street works at arrangement of facades. The essence of the method is that the plates are first glued and then nailed to the base. Then the surface is reinforced with a plastic mesh, plastered, covered with paint, varnish or other protective coating.

- Wireframe. Used in the repair of floors and ceilings. The plates are laid in a frame of boards, the cracks are closed with mounting foam. On top of the crate, a finishing coating is laid in the form of boards or panels.

- The intermediate layer. Roll or slab material is laid on a concrete slab or rough floor from thick boards. In this case, the interlayer is glued to the base in order to avoid displacement during installation.

When located underground, the material does not need additional protection if there is no risk of mechanical impact. When conducting outdoor work, protection from ultraviolet radiation and impacts is necessary.