Vent plugs and silencers are varieties of fittings for air exchange systems. Qualitatively assembled ventilation involves the use of these elements, simultaneously bearing a functional and decorative load.

Purpose of ventilation silencers

In factories, warehouses, in large entertainment centers, very powerful ventilation units are installed, characterized by a high noise level. The more powerful the equipment, the more noise it produces. The problem is solved by installing ventilation silencers. The price of the ventilation silencer is low, and the effect of its presence is very significant. The best results are shown by devices at an air speed of 4 - 12 m / s and in the range of sound vibrations of 500 - 4000 Hz.

Sound attenuators for ventilation are designed to reduce noise arising from the movement of air through the ventilation ducts.

Install a silencer immediately after the noisiest unit or before the room. The correct installation of noise measurements in the switched on system is controlled.

Installation locations:

- at the exit of a noisy room;

- after noisy equipment;

- in front of and behind the fan.

A silencer installed without preliminary calculations can significantly increase the sound load on the room.

In the course of acoustic calculations determine:

- length of ventilation silencer;

- channel area (for plate model);

- channel section (for tubular model).

Sound attenuators are installed in ventilation systems of all types except those through which radioactive air passes, filled with mechanical particles, vapors of aggressive chemicals, high humidity or temperature above +90 degrees. One system can use from one to 20 to 30 devices.

Types of Silencers

There are several types of silencers for ventilation:

- lamellar or rectangular;

- tubular.

Plate silencers for ventilation are a galvanized steel pipe of rectangular cross section, separated by ribs along. The distances between them are from 7.5 to 30 cm. The ribs are made of a basalt plate and covered with soundproofing material (mineral wool, glass wool, felt). If necessary, some of the ribs can be removed, but the smaller the distance between the ribs, the higher the sound insulation. At the same time, the resistance to air flow increases to reduce it, the surface of the ribs is treated with plastic or anti-abrasive material. So that, crashing into the ends of the ribs, the air does not create an additional hum, they are equipped with fairings.

They are used in systems with ventilation ducts with a diameter of at least 30 cm. They can be mounted vertically or horizontally. Air can be passed through a plate ventilation silencer with a temperature of not more than 70 degrees Celsius.

Tubular ventilation silencers are used in systems with ventilation ducts not exceeding 50 cm in diameter. Their design is very simple: two steel tubes (rectangular or round) mounted concentrically. The inner pipe is perforated, the outer one is solid. A sound insulation layer of 5 cm was laid between the walls of the pipes. The denser the material, the more effective the sound absorption. Sound insulation is laid in the form of soft, semi-rigid mats or a rigid plate. The standard length of the noise absorption section is 50 - 90 cm.

For round channels, tubular silencers are more often used, and for rectangular (industrial enterprises) - lamellar.

With the device installed, the noise in the room located near the ventilation equipment must comply with the sanitary standards for this type of room.

The price of a silencer for ventilation depends on its length. Standard products are produced 60, 90 and 120 cm long. But custom-made silencers for ventilation of any size and diameter. The price in this case is calculated in each case.

Purpose of ventilation plugs

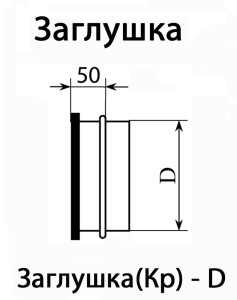

Plugs for ventilation are used to tightly close the duct circuit.

Vent plug functions:

- protection of the system from dirt, water, insects and rodents, dust;

- overlapping a separate duct branch from the common system;

- regulation of air intake into the room;

- prevention of air movement through ducts.

The shaped product prevents clogging of the air ducts, extends their life without additional cleaning, and ensures safety. In some ventilation systems, such as saunas, plugs are used to regulate air flow.

So that the plug for the ventilation holes fits tightly into the duct, it is selected in size. The plug tightly closes the pipe and withstands the pressure of the air circulating in the system.

Manufacture and installation of plugs

Plugs of various sizes and shapes are made for all existing types of ducts. In addition to round plugs for ventilation, there are rectangular and square. Round ventilation plugs are available in standard sizes, rectangular plugs are made to order for the exact size of the ducts.

The materials from which the ventilation plugs are made comply with the standards for ventilation ducts. As a rule, shaped products are made of galvanized steel. Zinc coating extends the service life of the vent plugs and protects against corrosion. More expensive vent plugs are made of stainless steel.

Sheet metal thickness 0.5 - 1.2 mm.

When installing plugs in the ventilation system, the following types of connections are used:

- nipple - the most common;

- on rubber washers;

- on flanges from a corner.

Round and square ventilation plugs are located in prominent places, so many manufacturers pay special attention to their decorativeness.

Vent plugs for baths and saunas

In baths and saunas, round ventilation plugs are used to decorate the outlet of the ventilation duct and regulate the air flow. A plug is usually installed on the outlet of ventilation ducts with a diameter of 10, 12.5 and 16 cm in the ceiling or wall.

The plugs are equipped with a decorative valve, which during rotation changes the intensity of the air flow. Valves for ventilation plugs for a sauna are made of special types of wood that do not rot in a humid and hot atmosphere of the bath and do not emit tar:

- Pine;

- Linden;

- cedar;

- alder;

- aspen.

The wooden valve looks very neat and stylish, its color is selected to match the tone of the wooden finish of the sauna walls. The casing is made of metal coated with a polymer layer that prevents corrosion.

Plugs for ventilation openings are used as outputs of natural and forced ventilation. They are sold complete with fasteners and instructions. The market presents products of Russian and Finnish manufacturers.

Special production technologies ensure a long service life of products.