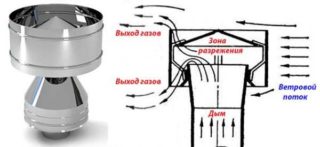

The deflector or reflector is a pipe structure of a special shape, mounted on the top of the chimney to protect the tip. Its main purpose is to increase the draft created in the channels of heating systems and ensure safe smoke removal. If a deflector is not installed on the chimney, air will start to penetrate into it, preventing the formation of a pressure difference inside and outside the chimney.

Brief information and principle of operation

In addition to its general purpose, which consists in the removal of gases, the deflector on the chimney performs a number of auxiliary functions:

- evens traction (increases oxygen supply), which leads to the saving of fuel that is completely burned in a heat generator or furnace;

- prevents the formation of sparks, which often lead to the ignition of combustible materials;

- protects tube cavities from precipitation and strong gusts of wind;

The use of a baffle ensures the uninterrupted operation of any heating device, even in bad weather conditions.

The principle of its work is based on the laws of aerodynamics. In simple words, it can be represented as follows:

- Moving air masses flow around the walls of the outer cylinder of the reflector, creating a vacuum in this place.

- Part of the airflow forms turbulences that rise along the body.

- They are mixed with the remnants of combustion products discharged from the chimney.

The resulting mixture creates additional vacuum and increases traction in the chimney.

Gaps are provided on the upper cylinder whereby smoke is drawn into the pipe. Because of them, the air turbulence formed under the hood sometimes prevents the escape of smoke, which is attributed to the flaws of the reflectors. To eliminate them, in some models, an inverted cone nozzle is installed under the umbrella, designed to reflect, dissect and subsequently remove air masses.

Reasons for smoke

The smoke of the furnace is most often explained by the so-called “traction rollover”, which occurs due to the long downtime of the heating system. This leads to cooling of the internal spaces and a decrease in the pressure gradient. As a result, the air flow in the pipe changes its direction and rushes not outward, but toward the heat source.

This phenomenon is in no way connected with the temperature outside and can occur in hot weather and in frosts. To eliminate the effect of reverse draft in the chimney, it will be necessary to increase the temperature in the outlet pipe. One of the ways that this can be achieved is to install a high-quality deflector for the chimney.

Nozzle types

The modern chimney deflector has many designs, the most famous of which are:

- Grigorovich nozzle;

- products manufactured in TsAGI laboratories;

- “Round Volper”;

- "Vane";

- H-shaped device.

- products of open type Astato.

Each of the listed varieties of nozzles for the chimney needs a separate consideration.

Products of Grigorovich and TsAGI

Grigorovich's deflector is the most affordable option that the user can easily make from improvised materials and pre-purchased blanks.The design includes two cylinders (upper and lower), as well as a system of nozzles, a cone and mounting brackets. Devices of this type have one significant drawback, which consists in the high position of the umbrella relative to the diffuser. This often leads to blowing puffs of smoke into its side niches. In general, the effectiveness of this device is not very great. However, the samples of these deflectors do a good job of another task - to prevent the penetration of rain and snow into the chimney.

The universal version of the deflector devices developed at TsAGI is made in the form of a pipe of a special shape fixed to the smoke exhaust pipe. In addition, it includes a diffuser, a ring and an umbrella nozzle. The advantages of this design include a special nozzle unit, which allows exhaust gases to be removed through the ventilation duct. Thanks to this, it is possible to increase the draft not only in the smoke channels, but in the existing exhaust and ventilation systems.

TsAGI design allows you to effectively dissect the air flow, which contributes to the rapid removal of smoke from the exhaust channel. The umbrella located inside provides reliable protection against climatic influences. A significant drawback of this design is the difficulty of manufacturing at home.

Round Volper and H-shaped deflectors

The device called “Round Volper” has a design similar to the TsAGI model. The differences are noticeable only in the features of the upper part of the deflector housing. A nozzle cap that protects the inside of the pipe from debris and sediment entering it is placed here on top of the diffuser, which eliminates some of the drawbacks of the TsAGI model.

The H-shaped model is simple enough to make it yourself. To assemble, you will need several pipe sections, designed for strong gusts of wind. Elements of this design are assembled in the form of a horizontally located letter H, which eliminates the possibility of atmospheric precipitation and debris entering the pipe channel. Vertically located sidewalls allow you to increase traction in the chimney and separate the outgoing flows in different directions.

Vane

The device consists of several visors interconnected, rotating on a needle base. So that the structure can rotate under the influence of wind, a special weather vane assembly is provided in its upper part. Some models are equipped with a small arrow pin indicating the direction of air flow.

The presence of visors, dissecting during the rotation of the air, allows to increase the draft in the chimney. In addition, with their help, it is possible to protect the boiler or furnace structure from pollution, which is possible due to small particles entering from outside. The disadvantages of this design include the unreliability of the bearing used in the mechanism of rotation of the wind vane.

Baffle ASTATO

Under this designation is another model of a rotating ventilation class vent, using for this not only mechanical, but also wind power. In its design, the following mandatory components and elements are provided:

- built-in electric motor;

- pressure meter;

- electronic time switch.

The latter is used to set the shutter speed, after which the operating mode changes. When the wind reaches a certain force, the built-in engine automatically turns off and the device operates on the principle of exhaust ventilation. With the weakening of the wind draft, the electric motor starts again, which does not worsen the aerodynamic characteristics of the system, but allows one to obtain the required vacuum (up to 35 Pa).

The electric motor of the deflector is quite economical, because it works only after switching on a signal that controls the pressure at the outlet of the chimney.The overwhelming part of the operational period, the deflector operates on wind power. If you want to switch the device from one mode to another, the user can manually.

Self-made deflector

Since the Grigorovich deflector is one of the simplest and most easily reproducible types of turbo protective devices that have a simple structure, it is most suitable for self-assembly. To make a deflector on a chimney with your own hands, you will need blanks of tin or galvanized steel with a sheet thickness of at least 0.5 mm. To assemble the deflector, it is also necessary to prepare the following set of tools:

- scissors for cutting tin;

- a hammer, an electric drill and a set of drills;

- welding machine of any type;

- marking kit;

- cardboard sheet;

- self-tapping screws and other hardware (nuts and bolts).

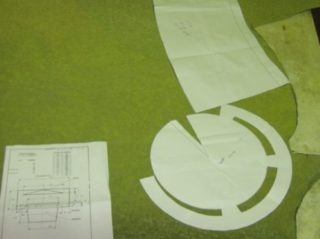

As the starting material, a galvanized sheet with a thickness of 0.8 mm was selected. In addition to them, you need to prepare a set of steel strips of a given width. A homemade device is assembled in the following sequence:

- The sizes of the designed device are calculated, for which ready-made formulas are used that are provided on the Internet.

- On a cardboard sheet, the marking of each of the working elements of the future design is applied.

- Patterns are cut out, which are then applied one to another to make sure that the contours match.

- Templates are placed on the surface of the prepared steel sheets and circled.

- According to the markup obtained, workpieces are cut using scissors.

- On the basis of the central part, a mold for a diffuser is cut out, along the edges of which holes are made for self-tapping screws.

- In the same way, a blank is formed for the outer cylinder of the deflector.

- At the penultimate stage of assembly, a cone-shaped cap is assembled from 2 obtained blanks.

In conclusion, six cuts are made along the edges of the upper cone, which serve to mount the support posts. The latter are cut from steel strips 21 cm long and 5 cm wide. With their help, two conical billets with their edges are fastened together.

The finished hood of the deflector is combined with the assembled diffuser, after which the whole structure is installed in the outer cylinder.

Device mounting

In order for the chimney to be reliably protected in its upper part, it is important to correctly install the finished deflector on its head. To carry out this operation, you will need to prepare the following tools and fasteners:

- electric drill with a set of drills;

- a full set of ring keys;

- mounting threaded rods and nuts to them;

- special connecting collars.

You also need to stock up on a ladder of suitable length, allowing you to climb the roof of the house and move along it. In addition, it will be necessary to prepare a pipe segment with a diameter exceeding the same standard size of the pipe channel.

The installation of a turbo deflector for the chimney is performed in the following order:

- In the upper section of the chimney pipe with an offset of about 8 cm from the edge, the marking of the holes for the fixing screws is applied.

- Exactly the same marks are made on a wide part of the body.

- Holes are drilled at marked points.

- Screws are inserted into them, and nuts are carefully screwed on the back.

- The finished reflector is mounted on the chimney and mounted on the head with the help of clamps.

If, for example, you have to install a deflector that is too large in size on the pipe of a brick house, it is recommended to use wire extensions of the required length to strengthen its fastening.