Every year, there is more and more demand for work related to installation, restoration of communications, if necessary. Especially often, such work is carried out in rooms that are used for cooking.

What is a duct

Air channels themselves simply do not exist. They become part of the whole system installed on a particular object. These may be systems:

- The removal of hot air from the boiler room.

- Pneumatic transport. It is used at the enterprises, at supply of hot air.

- Aspiration - a kind of dust-free ventilation.

- Smoke removal.

- Air conditioning.

- Heating.

- Ventilation.

Each of the existing systems has its own requirements for the cross section of the ducts. For example, it can be round or square. A set of requirements is presented for the materials that are used for manufacturing. These may include plastic, metal, stainless steel, and other options. Duct mounting should take these factors into account.

Causes of System Failure

Specialists analyze each situation in this area to understand the main causes of breakdowns. Thanks to this, problems are solved in a short time, with maximum accuracy. Professionals have established that faults mainly arise for two reasons:

Specialists analyze each situation in this area to understand the main causes of breakdowns. Thanks to this, problems are solved in a short time, with maximum accuracy. Professionals have established that faults mainly arise for two reasons:

- If the repair or installation of the ducts is carried out by persons without proper qualifications.

- With natural wear and tear on equipment.

Most often there are situations described in the first paragraph. Installation and restoration of the ventilation duct represent entire sets of work, all the nuances of which are familiar only to true professionals. Therefore, it is better to immediately trust them after acquiring suitable varieties of equipment. And turn to them when ventilation restoration is required.

Important Rules

There are only a few, but their knowledge is required. It doesn’t matter whether ductwork is installed on its own, or specialists are invited to do this.

There are only a few, but their knowledge is required. It doesn’t matter whether ductwork is installed on its own, or specialists are invited to do this.

- The so-called "sleeves" of the pipes should be stretched quite strongly. Then sagging will be eliminated. That will prevent losses in air pressure and pressure.

- For bends, it is recommended that you select the largest radius possible. If the turns are too sharp, we again lose in terms of pressure.

- Grounding of the trunk is organized necessarily. During the transport of air, static electricity can accumulate, because the air contains various organic components. Because of this, it is more difficult to clean the ducts.

- Protective metal adapters are mounted where channels pierce the walls. It is through these adapters that ducts are drawn in this situation. Otherwise, it increases the likelihood of damage to the sleeve due to the fact that it will come into contact with sharp corners belonging to stone surfaces. Then the restoration of the duct will not give the desired result.

- No more than 40 cm should be the distance between the elements responsible for the fasteners. The vibration of the channel will be too strong if the distance is greater. In addition, it contributes to an increase in sagging. It is recommended to observe this norm, even if after these actions the installation cost increases slightly.

About the features of fixing ducts

When fixing the air ducts, all craftsmen must adhere to SNiPs.Some of them must be respected, regardless of which materials were used to produce the ducts. And regardless of whether the restoration of the ducts in the kitchen.

It is necessary to create a separate label on the schemes, on which only the fasteners themselves are applied. Otherwise, it will not be possible to evenly distribute the load, given the trace.

Modern construction is characterized by the presence of a typical floor height of up to 4.5 meters. Fastenings are allowed only in the interfloor overlap, unless other varieties of parts are indicated in the design documentation. Interfloor overlapping has its own characteristics: it requires a tight girth of the duct along the entire length. Rectangular ducts are clasped with traverses, and round ones with clamps. At the same time, the level of fire resistance of the fasteners should not be lower than that of the ceilings themselves. This must also be taken into account when restoring the air duct in the kitchen.

Testing and commissioning

According to SNiPs, in this process only 4 stages are provided. But they must also be observed.

- First, hidden work is subject to examination.

- After proceeding to individual tests.

- Then - commissioning works.

- Finally, at the last stage, the object is put into operation.

There is a fifth stage of this work, in which fire safety systems at the facility are involved.

Individual testing

In total, three representatives are selected for testing:

- From the installation organization.

- From the general contractor.

- From technical supervision.

Tests are conducted to verify the operability of each electric motor. It is important to look for defects in parts and parts that rotate. This is especially important for the overall equipment supplied to difficult for installation places. If the equipment is defective, conducting preliminary individual tests avoids the additional cost. Even if you still need to restore the duct.

Many disputes are related to how long tests should be conducted. The SNiPs stipulate that their duration should not exceed 72 hours. For air conditioning and heating equipment, tests are carried out in accordance with recommendations from the manufacturers themselves.

Installation Rules for Horizontal Ducts

The sequence of work in this case will be as follows:

- Welding to embedded parts set the mounting elements. For this, you can use the construction and assembly gun.

- After that, they go on to create markings for the installation of mechanisms that have become indispensable when lifting nodes. At the same stage, towers, scaffolds and forests are being prepared.

- Separate details of air ducts are brought to the general design. On inventory supports, parts of the system are assembled into a single whole. On the floor, parts belonging to large ducts are assembled.

- Go to the installation of fasteners, clamps.

Air ducts are laid in several ways, which are most widely used. For example, in inter-farm space, on an overpass or an outer wall. In the same areas, the ventilation duct is restored.

Additional installation features

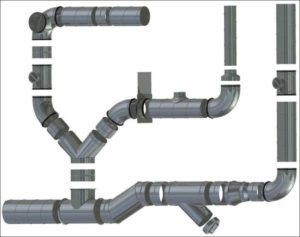

Ducts are different, different materials are used for their manufacture. They differ from each other in several ways:

Ducts are different, different materials are used for their manufacture. They differ from each other in several ways:

- According to the material used in the manufacture.

- By the presence of additional devices.

- In shape.

All these factors must be taken into account when the production of air ducts is organized. The ideal design option can be selected for almost every room, regardless of characteristics. The consumer receives guarantees of safety and quality only if the manufacturer and installers comply with GOST, this is their first priority.This also applies to works such as the restoration of the ventilation duct.

One of the first places in this market segment is occupied by the so-called galvanized air ducts. A wide range of applications provides an excellent combination of performance.

- High wear resistance.

- The lack of complex solutions in the design.

- Corrosion protection.

It is galvanized air ducts that are distinguished by the most attractive price. What are galvanized ducts? The thickness of the sheet, which became the basis for the creation of equipment, is at least 0.5-1.25 mm. The strength of the material is quite high, but the weight remains small. This makes it easy to clean ventilation systems.

If it is necessary to mount ventilation in office premises, preference is often given to rectangular ducts. They are also galvanized. They have a smaller cross section than their closest circle-shaped counterparts. What makes easier and restoration of ventilation.

But round ducts themselves are more often used for installation inside industrial premises. Thanks to this form, the aerodynamic characteristics increase markedly. Semi-rigid structures are required where there are hard-to-reach spots. The main thing is to take into account not only the shape, but also the thickness of the material used. The calculation is based on the characteristics of the air passing through the system.