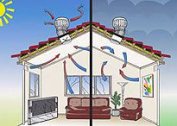

A new era in the production of ventilation pipes began in the mid-60s: in addition to traditional rectangular products, round pipes appeared. Only from the end of the 70s were scientists interested in air exchange in the rooms and after 10 years, the diameters of the air ducts began to be standardized. Today, the choice of ventilation pipes can satisfy any need. The thing is small: which pipes are better to choose and how to correctly calculate the ventilation parameters.

Ventilation pipe requirements

Supply and exhaust pipes for ventilation must meet the following requirements:

- tightness;

- level of aerodynamic drone, not exceeding sanitary standards;

- must ensure the free passage of air masses with a given project speed;

- to keep the air pressure corresponding to the project;

- comply with thermal insulation standards;

- fit into the interior of the building without taking up extra space.

Trying to find the answer to the question: which pipes are better for ventilation of a house or apartment, first we pay attention to the cross-sectional shape.

Rectangular and round ventilation pipes

Ducts can be round or rectangular. Round and rectangular ventilation pipes are used in supply and exhaust ventilation with forced or natural draft. There are 22 standard sections of round pipes from 100 to 2000 mm. Pipes with external diameters of more than 500 mm are classified as large. It is allowed to lay straight sections of highways with a duration of 2.5 to 6 meters.

Rectangular pipes are produced in standard sections from 100x150 mm to 1600x2000 mm in increments of 50 mm. Direct sections of highways can be no more than 2.5 m long. To connect the segments with each other, turns and branches, shaped ventilation elements of corresponding diameters and shapes are produced.

The shape of the section is selected depending on the size and purpose of the room. So, in small rooms with low ceilings, flat rectangular ventilation pipes will be less noticeable. Although in aerodynamic properties they are significantly inferior to round ones. This is explained by the fact that angles create resistance, increase noise and reduce the speed of air movement. Therefore, rectangular pipes in the ventilation of residential premises are additionally insulated.

When installing industrial ventilation systems, pipes of circular cross section with high throughput are more often used.

Plastic ventilation pipes

Metal and plastic are the two main competitors in the ventilation pipe market. Which pipes are better for ventilation: metal or plastic? The answer depends on the characteristics of the air environment and the requirements of the project.

Plastic rigid and flexible ventilation pipes are made from the following types of polymers:

- PVC or polyvinyl chloride;

- polypropylene;

- PVDF or fluoroplast;

- polyurethane or polyurethane foam.

Among the owners of small cottages and apartments, the most popular Pvc pipe for ventilation, as the most inexpensive, easy to install and easy to use. They are protected from destruction by ultraviolet and have a sufficient operating temperature range (from 0 to +80 degrees).

Plastic and PVC ventilation pipes have a number of advantages:

- the design is perfectly tight;

- the aerodynamic drone in the system does not exceed sanitary standards;

- PVC pipes for ventilation are cheaper than polyethylene and metal analogues;

- neat and look good in the interior;

- a wide selection of shapes and sizes of sections allows you to achieve the necessary system parameters;

- many plastic elements allow you to assemble a trunk of any shape;

- safe for human health, do not emit harmful substances.

Polyethylene pipes for ventilation are made with antistatic protection. Unlike PVC, polyethylene pipes for ventilation can be operated at temperatures of -40 to +80 degrees. Polyethylene pipes for ventilation with UV protection contain black soot, so they can be distinguished by color.

Polypropylene pipes withstand contact with aggressive environments and moisture, temperature from +1 to 98 degrees Celsius. Non-combustible and antistatic models are developed for special use. At low temperatures, the material becomes brittle, therefore it is used only in warm rooms.

The strongest and most resistant to aggressive environments pipes are made from fluoroplastic (PVDF). They are installed on the inflow and exhaust of air, they withstand contact with vapors by most alkalis and acids, the temperature is -40 to +140 degrees. Therefore, such ducts are installed to transport air masses containing the most aggressive components.

Many advantages make plastic pipes very popular in private housing. And only low fire resistance limits the possibility of using PVC pipes in industrial ventilation.

Metal ventilation pipes

Metal and tin pipes for ventilation are made from:

- galvanized black sheet steel with a thickness of 0.5 - 1.2 mm;

- stainless steel AISI 304, 321, 316, 430. Sheet thickness 1 - 5 mm;

- aluminum;

- galvanized steel;

- sheet steel black.

Ventilation pipes are rarely made from sheet aluminum, more often foil is used. Pipes for ventilation with a diameter of up to 50 cm are made of sheet metal 0.55 mm thick. Elements of large diameters are made of sheet steel with a thickness of 0.7 mm or more.

The advantages of hard metal pipes:

- durable, strong;

- smooth inner surface of the pipes provides good aerodynamics;

- dirt, dust and soot do not accumulate on smooth walls;

- withstand high pressure and temperature;

- due to their high hygienic qualities, they are used in facilities with high sanitary requirements;

- withstand the effects of aggressive environments.

Let us compare some characteristics of pipes made of various materials.

| Material | Minimum temperature | Maximum temperature |

| Stainless steel | -40 | +500 (short-term up to +700) |

| Aluminum (flexible uninsulated) | -40 | +130 |

| Galvanizing | -40 | +80 (short-term up to +200) |

| Black steel | -40 | +800-900 |

| PVC | -20 | +70 |

| PPU | +130 (short-term up to +150) |

Table 1. Range of working temperatures of ventilation pipes from different materials

Galvanizing. According to GOST standards, galvanized steel pipes are allowed to be used in areas with any climatic conditions for any type of ventilation except for the transportation of aggressive gas and air mixtures. A layer of zinc saves from corrosion of the pipe and even in damaged places when interacting with oxygen a protective film is formed.

Stainless steel. Corrosion-proof ventilation pipes are suitable for transporting aggressive air mixtures, hot vapors and gases. Pipes can withstand high temperatures and are very durable, therefore, stainless steel ventilation is often installed in plants.To ensure fire safety, stainless ventilation pipes are additionally wrapped with mineral wool.

Black steel. Black steel pipes are installed in ventilation, aspiration and smoke exhaust systems. They are characterized by increased heat and fire resistance, more rigid in comparison with galvanized or stainless. Due to the welds, the pipes made of black steel are sealed.

Black Steel Duct Features:

- made from cold rolled mild or hot rolled black steel;

- metal thickness 1.5 mm; 1.4 mm; 1.2 mm;

- pipe length from 125 cm to 250 cm;

- pipe connection by flange method.

Welded black iron pipes are available in round or rectangular cross-section. Inside and outside the pipes are primed.

The technology of production of metal ventilation pipes

When choosing the best pipes for ventilation, a certain role can be played by the technology of their manufacture. There are two methods for producing pipes for ventilation from sheet metal and steel sheet:

Method for the production of longitudinal pipes

The pattern of the future pipe is cut out on a guillotine machine. It comes to the profile bending and here, by the method of cold profiling, the pattern is folded along the length into a pipe of the required diameter. The edges of the sheet are fastened together by welding or folds. The second method is easier to implement and therefore more common. At the same time, additional material goes to the rebate lock, it does not provide tightness. You can solder or cook sheets from a thickness of 1.5 mm. Such a connection is hermetic, but more laborious.

Rectangular tubes are produced on roll forming machines. Round air ducts are cut in the same way, after which they enter three-roll machines for rolling to the required diameter. Pre-milling machine is set to the desired pipe diameter and metal thickness.

Method for the production of spiral-wound pipes

Making pipes in the second way takes less time, but requires more material. Strip - a metal tape is curled into the ventilation pipe. Setting up the machine for the thickness of the metal and the diameter of the duct is done by replacing standard dies. The production of twisted ventilation pipes eliminates complex fixing work: welding or rebate manufacturing. Therefore, the cost of twisted ventilation pipes is lower, and the technical characteristics are not inferior to longitudinal ones.

Flexible pipes for ventilation

Flexible ventilation pipes are made of aluminum foil or reinforced plastic. The aerodynamic properties of flexible ventilation pipes are relatively weak. Therefore, they are usually used to form corners in complex areas, including for transporting media with temperatures up to +250 degrees.

Aluminum ventilation pipes consist of several layers of foil. They are well bent, lightweight and easy to carry. Their length in the extended state increases 3 times. But the corrugated inner surface reduces the throughput of the ventilation pipe. In addition, dust is collected in the folds.

To mitigate the flaws, plastic and aluminum flexible ventilation pipes are installed only fully extended.

Polyester corrugated pipes for ventilation made of several layers of plastic and metal foil. Structural rigidity is given by the frame of red-hot steel wire. Plastic flexible ducts withstand temperatures from -50 to +70 degrees.

One of the main problems of flexible ducts is the high pressure loss along the route. They can be calculated using the chart.

Due to the low throughput, flexible ventilation pipes are suitable for systems with an air velocity of not more than 30 meters / sec and low pressure.Therefore, they can be safely recommended as air ducts for kitchen hoods and domestic exhaust fans.

Insulated ducts

Heat and sound insulated flexible ducts do not require additional sheathing of ventilation pipes. Insulated pipes for ventilation are released from plastic, at the same time they differ in increased sound insulation. The inner perforated layer is covered with special protection against diffusion, then there is a layer of mineral wool, which is protected by several layers of polyester and aluminum foil. The insulation thickness of the insulated ventilation pipe is 2.5 cm. Pipes of this series are produced in diameters of 10.2 - 50.6 cm. The insulated pipe withstands ventilation temperatures of -41 +135 degrees Celsius. The head of the insulated ventilation pipe will not freeze in the winter. Such ventilation pipes are suitable for roofs made of metal, soft shingle, ceramic tiles or corrugated board.

Sandwich pipes

Sandwich pipes for ventilation and smoke exhaust are also classified as insulated. They are two metal pipes arranged coaxially. The gap between the pipes is filled with non-combustible insulating material.

Ventilation sandwich pipes for chimneys are often made of high-strength stainless steel on welded joints. The outer pipe may be made of galvanized sheet, but ventilation made of stainless sandwiches looks better and lasts much longer. It is only necessary to put on the cap on the vent head and the exit is ready.

Such pipes are suitable for chimneys and outdoor ventilation, which according to the requirements of technical supervision must be insulated. Between each other sandwich pipes are connected by a bell-shaped method. The cost of a stainless sandwich pipe is 1 \ 2 higher than the combined one.

Textile ventilation pipes

New in Ventilation - technical textile pipes. Such air ducts are installed on the supply side and, thanks to their special properties, evenly distribute air throughout the entire volume of the room. Round, semicircular, or quarter-circular textile ducts are more common, but it is technically possible to produce rectangular ones.

Characteristics of textile ducts:

- work in the range of -40 +280 degrees;

- resistant to moisture and chemicals;

- antibacterial;

- have a small mass;

- textile ventilation pipes are characterized by high throughput;

- easy to repair and clean;

- serve longer than 10 years;

- combined with air ducts and elements from any materials;

- can be of different colors.

Due to the variety of colors, in many cases ventilation from textile pipes does not need to be sheathed with boxes. It neatly and harmoniously fits into the interior. Special purpose pipes have antistatic, anticorrosive or fireproof properties.

Diameter of ventilation pipes

Having decided on the material, you can choose which diameter of the ventilation pipes is optimal. Knowing the ventilation rate for your room, you can choose which diameter of the ventilation pipes is suitable. The rate of air exchange is determined according to the SNiP tables, it will come in handy later, but now it is necessary to determine the volume of the room by multiplying its overall dimensions.

Now we calculate the air exchange for a particular room:

O=n*Vto,

here Vk - the volume of the room, n - the rate of air exchange from SNiP.

As a rule, for residential premises it is enough to determine the air supply or exhaust. Industrial ventilation is built on the basis of both indicators. Having received the value of O, it is necessary to increase it so that it is divided by 5.

The values of the inflow and exhaust should be a ratio that depends on the purpose of the room. For residential premises, the inflow and exhaust are always the same.In production, it is often necessary to back up the air in the service area or, on the contrary, discharge it.

When the total air volume is obtained, according to the diagram, we choose which diameter of the pipe for ventilation is optimal. And another value that is important for the quality of the system: the length of the length of the exhaust ventilation pipe above the roof.

The length of the section of the exhaust ventilation pipe depends on the cross section and is selected according to the table. The width in the leftmost column, the section in the grid, and the height of the head of the ventilation pipe in the top row.

- The length of the ventilation pipe must be equal to the length of the chimney. Otherwise, smoke cannot be drawn into living rooms;

- Above the flat roof, the height of the pipe should be more than 50 cm.

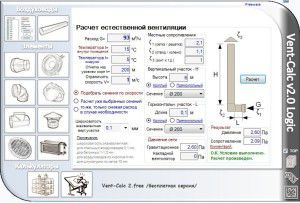

Calculation using the program

The use of special programs greatly facilitates the calculation of all ventilation parameters. The calculations take into account climatic indicators, the shape of the pipes and even the material from which they are made. An additional resistance to the air flow in ventilation is created by gratings, filters, grids and turns, which is also taken into account in electronic calculation.

Video on how to correctly calculate the height of the chimney: