The problem of ventilation is very acute for residents of apartment buildings. On the one hand, sealed plastic windows do not let air in. On the other hand, low-quality exhaust ducts create the effect of reverse traction. The air stagnates, mold appears on the walls, condensation on the glass. The issue of air flow is solved with the help of ventilation valves for plastic windows. Installation of which is mandatory for new buildings, and in most developed countries they have been used for more than two decades.

The problem of reverse draft in the ventilation of residential buildings is solved with the help of ventilation grilles equipped with air flow valves. Read about what these devices are and what are the reviews on the supply ventilation valves for plastic windows.

Residential air exchange

In the design of most residential buildings to this day, standards created 20 years ago are used. Then wooden frames were installed, through the slits of which an influx of fresh air into the dwellings was provided. Therefore, it was necessary to take care only of the withdrawal of the already worked out: through the mines, leaving the ventilation grilles with check valves to the kitchens and bathrooms, and the other end beyond the roof level.

There could be no mold and condensation in houses with split wooden windows. Today, tightly covered rubberized wings do not let in a gram of air. This means that the gases and vapors emitted by people also remain in the apartments.

For reference, moisture is released in 1 hour:

- when bathing in a hot shower - 2 liters;

- when boiling in an open container - 0.9 liter;

- when burning 1 gas burner at full power - 0.4 liters;

- when breathing in a calm state - 50 grams;

- while breathing during exercise - 0.4 liters.

To provide a person with enough fresh air, 25 cubic meters per hour is required. This means that every hour you need to make a draft for 5 minutes, letting oxygen into the apartment. It is unlikely that this method of ventilation is suitable for someone in the winter.

Arranging a fairly common "slit" ventilation, tenants launch air at the bottom of the window. The cold drops to the floor, while the upper layers of the air are not affected, where carbon dioxide accumulates, excess heat and moisture. This method of air exchange significantly reduces the noise insulation of windows - one of the main advantages of PVC structures.

The noise insulation index of plastic windows is:

- in the "window" mode - 9 decibels;

- with slot ventilation 18 decibel;

- with the window closed - 34 decibels.

Slit ventilation threatens the penetration of thieves (on the ground floors), dust and allergens into the apartment, as well as a significant decrease in temperature.

Lack of ventilation poses a risk to human health due to the accumulation of high concentration of radon gas in apartments. This completely invisible gas is released from the earth and some building materials, concentrated in homes and causes severe fatal diseases. There is only one way to deal with radon - ventilation.

Ventilating supply valves

One of the best ways to ensure the flow of air today are ventilation valves for plastic windows.

The ventilation valve is installed directly on the sash of the plastic window. Air enters the room with the window closed.The design of the supply ventilation window valve made of plastic is such that the air is directed to the ceiling without creating a draft and without blowing into the backs of people in the room.

Advantages of ventilation valves for plastic windows:

- The valve passes 25 - 35 cubic meters of air per hour, providing a rate of oxygen;

- Good valves are soundproofed up to 42 decibels in a fully open state (more than some PVC windows);

- There are no jumps in temperature and humidity in the room;

- No drafts;

- The valve operates without power from the mains;

- The air flow is directed in such a way as to provide maximum comfort for residents and natural convection;

- The ventilation valve for plastic windows constantly passes air, preventing radon from accumulating in the house. Models of some manufacturers do not completely close at all, which prevents icing of the wings;

- The valve is small and does not close the glass;

- Installation of ventilation valves on plastic windows is possible not only in the factory, but also at home. To do this, you do not need to remove the glass;

- There are models of ventilation valves with hidden installation on plastic windows, they are completely invisible. The average dimensions of the valves are 30 cm x 7 cm x 2 cm.

The cost of a ventilation valve for PVC windows is from 20 to 40 cu, which is a very small addition to the price of the plastic windows themselves. According to reviews of supply ventilation valves for plastic windows, after installation, the air in the apartment improves markedly and it becomes easier to breathe.

Cons of ventilation valves:

- The valve works only with high-quality exhaust ventilation;

- If there is no ventilation duct in the room (or adjacent to it), the installation of the valve is useless;

- In winter, it is not advisable to completely shut off the valve to prevent icing, condensation;

- Not all models cope with work in severe frosts.

Mounting the ventilation valve

Installing a ventilation valve on a plastic window takes only half an hour. It is not complicated and does not require special skills, it is much cheaper than installing a wall inlet valve.

The ventilation valve for plastic windows is installed directly on the sash, at a height of at least 1 m 80 cm from the floor.

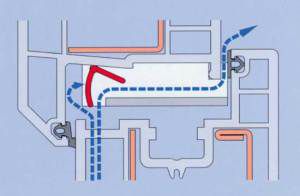

Most ventilation valves consist of two parts: street air enters through the lower part and is transmitted to the room through the upper. A small portion of the sealing rubber is removed on the frame, where the valve insert is located. The mechanism of the upper part of the valve is similar to two square bars. They have holes through which air and longitudinal petals penetrate. When the pressure inside the room decreases, the petals move and air enters the apartment.

Some valves are mounted with a milled window profile; others involve several types of installation. There are special models for blank plastic windows.

If necessary, the valve can be easily dismantled.

Vent valve control

There are models of ventilation valves for PVC windows with manual control, automatic or completely without it. The price of devices varies significantly. Almost all devices are equipped with protection against gusts of wind.

Experts recommend dwelling on models with at least manual control, since in some situations it is necessary to completely block access to the cold air room. For example, if there are no people in the room, the inflow can be stopped and saved on heating.

On the other hand, with manual control, there is always the possibility of opening the valve too little, creating stuffiness or too much and cooling the room. Therefore, the most convenient valves with automatic adjustment. Their design includes a humidity sensor, which opens and closes the leaves on time.

The difficulties of operating valves in the winter

Most models of ventilation valves for PVC windows are developed in Europe, where there are no cracking frosts.

Therefore, falling into the conditions of harsh Russian winters, they can create some problems.

For example, the valve may freeze or fog. This should be considered when choosing a valve. According to reviews, there are already models of supply valves for plastic windows on the market that provide ventilation at -45 degrees.

Whether the valve will freeze and “cry” or not depends on its design: how exactly the icy air is supplied into a warm room. You should know that at the same relative humidity (%), the absolute humidity in grams per cubic meter in the cold season will be completely different. For example, at 60 percent humidity and a temperature of -20 moisture in the air about 1 gram per cubic meter, while at +20 about 10 grams per cubic meter.

Penetrating through the supply valve, the air will cool it, but moisture will not settle here if the walls come in contact with the icy street air, and not with the moist and warm air of the room. To understand this principle, look at the ajar window pane, it will never fog up.

To prevent condensation from settling on the valve, its cold parts should not come into contact with warm parts. At the same time, it is impossible to be sure in advance that the acquired valve will not “cry”. The appearance of ice or moisture on the valve depends on humidity and temperature inside and outside, the movement of air around the valve, as well as its operating mode.

About valves on ventilation grilles

Some owners of apartments in high-rise buildings are faced with such an unpleasant phenomenon as reverse draft ventilation. The neighbors fry cutlets, and you inhale their aroma, spreading through the exhaust ducts. The cause of the problem may be a damaged or clogged ventilation duct. Often, its repair and diagnostics are not available to residents. But there is a simple, cheap way to fix the problem. Some apartment owners prefer to completely block the ventilation grilles, which is wrong. It is necessary to provide them with a check valve.

Ventilation grille with non-return valve completely solves the problem of air penetration from the common riser into the apartment. The non-return valve for the ventilation grill is a simple, inexpensive device, which is a cylinder with a leaf rotating in the horizontal plane or two wings fixed in the form of butterfly wings. The last device is called a butterfly.

A valve correctly installed on the ventilation grill releases air from the room, but does not allow it to enter back. The airflow from the ventilation duct tightly presses the petals to the valve.

The ventilation grille with a non-return valve for the kitchen can be used alone or in combination with an exhaust fan.

In this case, the fan is installed from the kitchen side, and the valve from the ventilation duct side. By the same principle, ventilation grills are used for hoods with a non-return valve.

Check valves on grilles are very useful if exhaust ventilation at home does not work at all. A fan blows air out of the kitchen, and a valve prevents it from coming back.

There are more complex designs of check valves for ventilation grilles. They are used in industrial forced air exchange systems. And most often installed on the entrance to the ducts from the street. Such air flow check valves on the ventilation grilles prevent the penetration of cold air from the street when the system is not working, down, insects and dust.

See how to make a non-return valve for the ventilation grill with your own hands.