Modern standards for the construction of multi-storey buildings provide for the creation of air pressure in the elevator shafts, which facilitates the evacuation of people using elevators in case of fire.

Scheme of ventilation of the elevator shaft

According to the Building Code, it is necessary to provide a minimum pressure of 20 Pa in the elevator shafts. A stream of air is directed from above the shaft, squeezing out smoke coming from below during a fire. In mines of specialized fire-fighting elevators, pressure should be provided from 40 Pa. Ventilation equipment, pressurization for ventilation of elevator shafts is installed during the construction of the building in the last stages. There is the possibility of arranging smoke ventilation for elevator shafts of existing tall buildings. In many buildings already commissioned, ventilation design for the mines was not carried out. But the installation of equipment for air intake and smoke removal is possible even in populated houses.

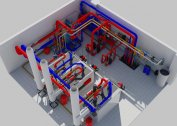

Coal mine ventilation

The main goal of ventilation of coal mines is to provide the necessary amount of clean air for all tunnels and passages in the mine, as well as to reduce the amount of toxic impurities, gases, and dust that cannot be eliminated by other methods.

In coal mines there is a chance of an explosion, since the air is filled with coal dust, gases. Therefore, to prevent poisoning of workers, explosions and fires, a system for degassing formations and designing ventilation for mines is equipped.

It is carried out by laying ventilation shafts and wells.

Ventilation can be central or flank, as well as combined.

There are three mine ventilation schemes:

- Suction;

- Injection;

- Combined.

According to the central scheme, air is supplied through the wells and is diverted through them. A ventilation well is a large diameter well drilled specifically for ventilation of a coal mine. It is used mainly for the outflow of air and gas from the mine. But sometimes as a supply channel. The central ventilation scheme of the mine is equipped in mines of small area and power, when working at great depths.

A more perfect scheme is central with the assignment of the ventilation duct. Air is supplied to the central channel, and discharged through a system of pits located in the mine bends. Convenient for shallow but branched shafts.

For ventilation of a coal mine of a large area, highly contaminated, ventilation sections are used that are installed at a distance from each other and covering the entire area of the mine.