A cellar is a place to store supplies, for example, agricultural products. Usually, for this, they will equip the basement in the house or dig a hole and close it from above. The cellar provides a suitable temperature and humidity, allowing the products to maintain their properties and freshness. The temperature in the house is very high to store the crop, and in the street in winter it is very low. Raw foods are stored at a temperature of 1-4 degrees. To maintain the freshness of the crop for a long time, it is necessary to monitor the humidity.

For optimal operation of the cellar, it is important to keep the following conditions:

- blackout;

- fresh, clean air;

- low temperature (approximately + 2-5 degrees);

- humidity is about 85-95%.

The last three conditions are provided precisely by the ventilation system for the cellar. In order for your vegetables, fruits, pickles, jams, wines to retain their properties, proper ventilation of the cellar is needed.

How it works?

Before you start building your own ventilation system, you need to understand the principle of its operation.

Winter ventilation

In winter, the operation of the ventilation system is most effective. In winter, at home about 25 degrees. In the basement - about 4. On the street in winter, conditionally 10 degrees. Warm air is lighter than cold, so it tends to rise. He rises to the ceiling of the cellar and goes into the chimney. Cold air outside will not interfere with this movement. In the cellar there is a discharge, with the help of which the effect of drawing in a new portion of warm air from the house occurs. It is full of moisture, which remains on the floor, but not on food.

Soon enough, an equilibrium of evaporation and condensation is formed, so the air humidity does not increase, but remains stable. The movement of air demonstrates Bernoulli's law: the air masses above are always in motion.

Another reason to make ventilation in the cellar is the risk of mold on the food. Mold fungi multiply when the relative humidity in the room is more than 75%. Low temperatures impede this process but cannot stop it. Humidity in the air appears due to the vapor concentrating from above.

You need a device that removes these pairs. Of course, it is best to make a ceiling in the form of a dome, and at the top to equip a pipe into which evaporations will escape, but this is not always convenient and possible.

Usually enough that in different corners of the room installed ducts for ventilation. Air begins to circulate if you install the inlet duct near the floor, and the supply air near the ceiling in another corner of the cellar 50 cm from the floor. Thanks to this, you can ensure maximum effect. The supply air duct carries fresh air into the cellar. Contaminated air is naturally removed through another duct. Such a simple device can be easily made with your own hands.

Summer ventilation work

In summer, such "natural" ventilation is less effective. What can be done to increase efficiency? The ventilation system in the cellar is equipped with an electric fan. It must be installed with your own hands in the lumen of the accessory duct. This will help speed up the air exchange process. The fan pumps air, so the room dries quickly even in summer with high humidity. You can install fans in both ducts. This is done if the cellar has a large area.Such ventilation for the cellar requires a lot of energy.

Do-it-yourself ventilation installation for a cellar

Understanding the processes that occur during ventilation makes installing a ventilation device easier.

So, it is necessary to perform the following manipulations:

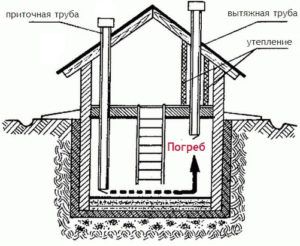

- Install two pipes for ventilation: exhaust and supply. It is important that the air exchange takes place more efficiently, the pipes must be located at different levels and in different places. So fresh air will not be sucked in.

- The exhaust pipe should be located on top, near the ceiling of the cellar above the products. Its upper part must be brought out through all the ceilings to the roof of the house.

- The supply pipe must be installed below, at a distance of 0.2-0.3 m above the floor. The ventilation pipe must be above the ridge of the roof or roof. Only in this case will air be effectively discharged.

- Outlets of ducts must be equipped with visors or deflectors for protection.

- If you install the duct near the chimney, then the draft will increase in the chimney due to heating. Take this opportunity, if you have one.

- It is advisable to provide both ducts with flaps to prevent possible freezing of the cellar during severe frosts.

- Install a metal grate at the inlet of the flow pipe. So you prevent insects and rodents from getting into the cellar.

What pipes are suitable for the ventilation device?

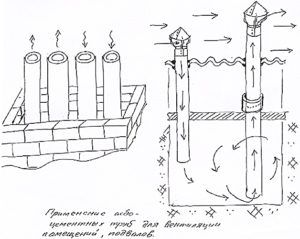

Pipes for hoods are made of the following materials:

- from low pressure polyethylene;

- from asbestos cement.

Both of these materials are reliable, strong and durable. Their difference is that polyethylene pipes can be easily mounted with your own hands. However, in order for the pipe to fit for the ventilation device, most likely, it will be necessary to weld the pipes. This is difficult to do the first time.

In order to choose the right material for ventilation pipes, you need to take into account the properties of your area. In this case, it is better to consult with a specialist.

In addition, the choice of material for pipes is not so important. If you have pipes of a suitable size, even those that were previously used, you can install them in your cellar.

How to make a calculation?

In order to make the correct calculation of the diameter of the pipe, you need to know the total area of the cellar. If we take its value as X, then the duct area should be equal to the product of X by 25 square meters. see From the area of the circle (round ventilation pipe), we calculate the radius of the pipe S = PR ^ 2. Therefore, the diameter is equal to two radii. It is easy to calculate on a calculator.

There is another calculation formula. L = V * K. It is determined by the air flow rate L. V is the volume of the cellar, and K is the number of times of air exchange per hour. Then apply the formula S = L / (W * 3600). S is the cross-sectional area, W = 1 m / s. Next, according to the circle formula, we calculate the radius.

Of course, this calculation is conditional, since it does not take into account the intensity of air exchange in the cellar. In addition, the minimum number of air changes was also taken. In some cases, the number of times when an air change should occur takes more. But it is important to understand that “more” is not equal to “better” in this case. Your products may dry out due to the large amount of clean air. If you doubt your calculations, then consult with a specialist.

The exhaust pipe should be at a distance of 1.5-1.8 m above the floor, and on the other hand install a flow pipe. It should be 0.2-0.3 meters above the floor. The ventilation scheme of the cellar necessarily includes this calculation, even if it is done with your own hands.

Forced ventilation

Natural ventilation for the cellar is not always convenient. The effectiveness of its work depends on the weather. In summer, it is not effective due to a slight difference in temperature.For the summer period, forced ventilation is better suited, that is, ventilation using a fan. It is installed in the exhaust duct. It is undesirable to install a ventilation device in the supply duct, because if the blowing duct does not pass polluted air efficiently enough, it will be blown out through the slots.

Fans are axial and duct. They differ in the principle of action and location. Duct fans can be mounted independently in the center of the exhaust duct. Axial fans are usually installed near the "exit". Duct fans should not have too high performance. This will power it from the unit. Amplitude fans have a higher Efficiency, so they are most beneficial.

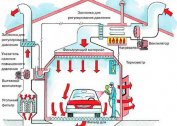

Automated ventilation

The constancy of temperature and humidity is especially important for wine cellars. Naturally, ventilation for the cellar will not be able to perform this function in any case, because the draft in it depends on weather conditions. The stability of temperature and humidity can provide only climatic technical means of high quality.

In this case, the calculation and development of technical requirements for the preparation of the premises is especially important. An irresponsible attitude to this issue may result in a violation of the conditions inside the cellar subsequently. Therefore, miscalculations of the load on the places of power supply output, correlation of the cellar area with the necessary equipment power for work, and other details of the preparatory work should remain in attention.

A stable climate can only be ensured by professional installation. Do-it-yourself installation is possible, but subject to preparation for this and careful study of the issue.

Important! If you need to install a split system (in order to maintain a constant climate), it is better to contact a specialist on this issue for help.