Buildings of any purpose, sizes and shapes need ventilation. Therefore, there are many types of ventilation units. The smallest ones are slightly larger than the size of the laptop, and to accommodate the largest will have to allocate a special room. We will talk about how the portable ventilation unit differs from the telescopic one, why we need a dust collecting ventilation unit and reveal the secrets of servicing various systems.

Types of ventilation units

Structurally, all ventilation units are divided into monoblock and type-setting.

In addition, in terms of functionality, they can be:

- inflow;

- exhaust;

- supply and exhaust;

- air-curtains.

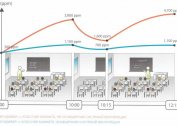

Supply ventilation unitssuch as Marta are used to supply clean air to apartments, offices and production facilities. The supply air volume complies with the standards and is sufficient to ensure the life of people. Before entering, the air is filtered, heated in the winter or cooled in the summer. Air is supplied to each room through air ducts. Automation controls temperature and humidity indicators, if necessary, includes heating or drainage. In addition to filtering, all additional options are considered optional and are provided at the request of customers.

Exhaust ventilation units They are used to exhaust the exhaust air and equalize the pressure when the supply is working. Their design is simpler than supply, and installation is cheaper. Equipment can be installed in the attic, between ceilings or on the roof. Telescopic ventilation units belong to this category.

The most practical settings are supply and exhaust. They are widely used in residential, public and industrial premises for various purposes. The complexity of installation depends on the specifics of the object, and in operation the equipment is quite simple, since the main control function lies on the automatic module.

Air and air curtains used where it is necessary to separate the zones of cold and warm air, not allowing them to mix. For example, at the entrance to a workshop or a large store. Vertical airflow saves heating costs by preventing heat from flowing out into the street. The air curtain does not allow street dust, fluff and insects to enter the room.

Mobile ventilation units

Mobile ventilation units belong to the category of industrial equipment and are necessary for servicing hard-to-reach places in rooms without ventilation: garages, tunnels, wells, large tanks.

A mobile ventilation unit is a module mounted on a frame made of a metal corner on wheels, equipped with a brake and a handle for moving. Ducts of mobile ventilation units are made of polymer corrugated pipes.

Restriction on the use of portable ventilation units: the presence of dust and particulate matter in the air is not higher than 100 milligrams per 1 cubic meter of air. Temperature up to +80 degrees Celsius. The absence of aggressive impurities.

Portable ventilation systems are widely used in production and in construction (for example, during welding in confined spaces).

Telescopic ventilation units

Telescopic ventilation units are designed for ventilation of granaries.

Sections are connected to a powerful fan. To make the installation more convenient to move around the ventilated room, the telescopic tube is mounted on a slide.

The unit is stretched across the floor and connected to the fan before loading the grain. As necessary, the fan is turned on and purged grain.

As a rule, a ventilation telescopic installation consists of 5 links that are inserted into each other.

When it is necessary to pull out the telescopic tube, it is first disconnected from the fan, then pulled out by the tractor for the cable provided for this.

Characteristics on average:

- productivity of about 20 thousand cubic meters per hour;

- the length of one section of the telescopic pipe is 2 m;

- installation weight without fan 170 kg.

Dust collecting ventilation units

Dust collecting ventilation unit is designed to filter air from chips, metal dust and other inclusions that appear during the operation of grinding, grinding and cutting machines.

Dust collecting plants are used for ventilation of glass, metal, woodworking production.

The dust-collecting ventilation unit drives air through bag filters and a dry cyclone, which eliminates 99.9% of existing impurities. They are collected in a special compartment at the bottom of the device. Such a plant has a capacity of 2 thousand cubic meters of air per hour and can serve only one machine.

Compact air handling units

These are small monoblock devices designed to air one room. The most famous representatives of the ventilation systems: “Sphere”, “Marta”, “Aeropack”, “Tion”. Unfortunately, the installation for ventilation "Sphere" is temporarily discontinued.

Ventilation units for the Marta tributary and others can be used in living rooms and offices. They work in non-stop mode.

Other characteristics of dust collecting ventilation units:

- productivity is about 120 cubic meters of air per hour;

- noise up to 40 decibels;

- power 40 W / h - 1 kW / h;

- three speeds of air supply;

- air filtration;

- air heater with a power of 0.8 - 1 kW / h.

The principle of operation of the forced-air ventilation installation "Marta"

The housing is mounted on the inside of the house. Through the intake pipe, air is supplied by the fan to the heater, then it is filtered and discharged into the room.

A characteristic feature of the Marta ventilation system and some others is air recirculation. Thanks to what the device does not freeze even at very low temperatures.

Properties and advantages of ventilation units

Ventilation installations offered by the market have a considerable number of advantages:

- Compact and easy to use. For example, the installation of the Marta ventilation installation can be carried out by the owner himself, having spent quite modest means;

- A large selection of installations for ventilation with recuperators, air conditioners, mobile, typesetting or monoblock allows you to choose the best option for a room of any size and purpose;

- A wide selection of options allows you to save, if necessary, on secondary functions;

- Modern installations are quite economical.

Complete set of installations

Any ventilation installation, whether it be Sfera, Marta or industrial with recovery, consists of the main modules:

- Fans They distill the air inside the premises and draw them out. In household models, axial fans are used; in industrial models, “snails”;

- Ducts. Air is transported through them to the right place. Their walls should be as smooth and airtight as possible. Air ducts are made of plastic or sheet metal;

- Non-return valve. It is installed from the street to the air duct to prevent blowing of cold air when the equipment is turned off;

- Automation and security system. A set of sensors and controllers that regulate the operation of the entire ventilation unit with recovery;

- Safety grilles and shutters. Protect air ducts from dust, insects and small animals. The grill is installed on the front of the building, so sometimes it carries a decorative load;

- Filters, heaters, air conditioners. With the help of these modules, air acquires the best performance: it is cleaned, brought to the desired temperature. Air-conditioned ventilation units are very popular in office buildings.

Air handling unit maintenance

Air handling units with air conditioners, recuperators and filters need periodic inspections, adjustment and cleaning.

Service Tasks:

- Inspection of fastenings and integrity of mechanical parts;

- Density control of duct connections, filters;

- Visual control of the integrity of the fan impeller and valves;

- Cleaning or replacing filters;

- Air condition monitoring;

- Valve tightness testing;

- Inspection of ventilation ducts;

- Checking temperature and humidity sensors;

- Checking the tightness of joints, including inspection of all welds;

- Checking the condition of the wiring, measuring the voltage levels on the main modules;

- Testing the operation of coolers and heaters.

Usually service is carried out once every 6-12 months. But in some types of industries, prevention is needed once every 2 months.

Now more about the checks of various units of ventilation units.

Fan

During prolonged or intensive use, the transmission belt from the engine to the fan may wear out. The belt sags, the engine idles without driving the fan. The slippage of the shafts also results in abrasion of the belt. Therefore, they must be periodically tightened. A complete belt change takes approximately half an hour.

In addition, the fan design has bearings. From time to time, they should be replaced, otherwise the load on the engine increases, it overheats and may fail.

And the main procedure is cleaning the fans. A layer of compressed dust accumulates on the blades and grids, which interferes with the work.

Air dampers

The damper is installed in the supply system on the air intake. When the ventilation is turned off, the damper does not let the cold street air in.

The damper may work poorly if the wiring is damaged, the device is icy or clogged with down, dust.

The condition of the air dampers must be checked at least once a year before the onset of cold weather.

Filters

Air passing through the damper is immediately supplied to the filters. In supply ventilation, disposable filter cartridges are usually installed, which must be changed periodically. The filter service life can be from 2 to 6 months.

Exhaust plants also have filters that purify the air before being released to the outside. They are especially important in industries with the release of dust, chips, harmful substances. Such filters can be cleaned or also changed depending on their type.

Valves

Valves are installed to control the flow of coolant in the supply system. From time to time they need to be checked and adjusted.

Poor operation of the ventilation valve causes system malfunctions and an unjustified increase in energy consumption.

Pumps

In supply ventilation systems, mixing pumps are used. Their function is in the constant movement of water through the heater.

Damage to the water pump causes serious malfunctions in the operation of the installation, its stop and leakage.

Sensors

A large ventilation unit certainly contains several sensors that monitor the operation of actuators (dampers, fans, pumps, and others).

The adequacy of the control of all ventilation depends on the sensors.

They transmit to the controller data on the parameters of the air environment, the operation of various mechanisms and components.

Sensors are tested once every 6 months in late autumn and early spring.

Heat exchangers

Dust accumulates on heat exchangers, which reduces heat transfer, which means ventilation efficiency. The condition of the heat exchanger depends on the cleanliness of the filters. So, with their timely washing or replacement, the heat exchanger will have to be cleaned only once every few years.

One of the best technologies for cleaning heat exchangers is soft blasting:

If the ventilation unit is not equipped with an automatic control system, such as Marta, the owner himself can carry out inspection and cleaning. Complex installations with branched ducts are serviced only by specialists. The cost of service depends on the capacity and type of installation.