The German company Al-Ko has existed in the market of caravans, HVAC equipment and garden accessories for 90 years. In Russia it represents a line of pumps (borehole, centrifugal, well). The specifics, advantages and disadvantages of Alco drainage pumps for dirty water are aspects that need clarification.

Lineup and Specifications

Units from Al-Ko, for pumping contaminated liquids, are represented by several models with similar technical characteristics and insignificant differences in structural solutions.

- DRAIN 7000 - a unit with a capacity of 7 m3 / h, a capacity of 350 W, a maximum immersion of up to 5 m, a feed height of up to 6 m; the outlet is 41.9 mm; the permissible fluid transfer temperature is 35º. Dimensions - 11.3 x 15.1 x 30.8 cm, weight - 4.4 kg, cable length -10 m.

- DRAIN 7500 is a device with an electric drive. Pump parameters, maximum values for immersion depth and feed height, inlet diameter, cable length are similar to the previous model. The differences affect power and performance - 450 W and 7.5 m3 / h. Used for heavily contaminated liquids - up to 5% of impurities and dirt with a diameter of up to 30 mm.

- DRAIN 7100 Classic with a vertical installation for contaminated water with a filter particle size of up to 35 mm. Throughput - 7.1 m3 / h. power - 430 watts. Equipped with automatic control of the float type water level and protection against dry running.

- The DRAIN 10000 Comfort is equipped with a 650 W motor. When the pump is immersed to a depth of 5 meters, it allows you to raise water to a height of 8 m. With a mass of 5.7 kg, the unit is characterized by a maximum capacity of 10 m3 / h.

The models are equipped with a float sensor, an automatic level control system, a shaft made of high-strength stainless steel, a housing made of polypropylene and fiberglass, corrosion protection, a universal angle fitting and a combined nipple. The mode of use is mobile and stationary.

- DRAIN 10000 HD is characterized by a power of 1300 W, water supply to a height of 10 meters. The maximum capacity at 10 m3 / h, the permissible immersion depth is 7 m, the size of the filtered mud grain is 38 mm. It is characterized by multilayer sealing, an outlet with a diameter of 59.6 mm.

- TS 400 ECO - oriented to work in dirty water with solid particles with a diameter of 30 mm. Power - 400 W, throughput - 8 m3 / h. Weight - 4, 35 kg, plastic case. Funnel impeller. The kit includes a universal corner adapter.

Unsuitable for use with potable water, saline and sand or aggressive chemicals.

Principle of operation and arrangement of Alco submersible drainage pumps for dirty water

The Al-Ko submersible units are based on the centrifugal principle, in which the liquid is sucked in by the lower part of the device, moves and is pushed out along the side pipe. A rotating motor transmits movement to the impeller. The movement of fluid occurs due to the generated pressure.

The following are distinguished in the list of design features of electric pumps for dirty water:

- shockproof case, tight connections;

- stainless steel and special shaft processing;

- funnel impeller;

- built-in thermal relay protects the engine from overheating;

- the float switch is regulated by a cable clip;

- the transitional branch pipe of the drainer is characterized by free rotation and cross-section of various diameters.

In aggregate, the manufacturer created a compact and maximally functional device. Solving the issues of pumping contaminated water is not difficult.

Criterias of choice

The correct selection of equipment depends on the knowledge of the required parameters. The focus is on:

- engine and its power;

- height of water supply;

- allowable immersion;

- bandwidth;

- permissible sizes of suspended particles.

These parameters are required to study when choosing a submersible pump model.

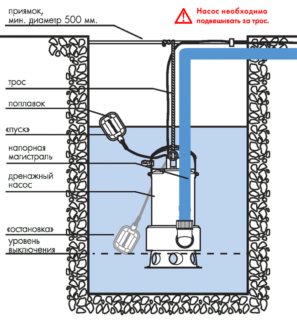

Installation Features

Designs are used for pumping contaminated water from wells, wells, basements. Traditionally, devices have a vertical installation, in which the body is immersed to a certain depth. The pipe must be above the surface.

When connected to the network, the work starts automatically and ends when the water level reaches its minimum level. Float switch trips.

Advantages and disadvantages of Alco pumps

Benefits of using these submersible devices:

- wide range;

- nice design;

- power, reliability, strength, compactness, versatility;

- high performance (7-11 thousand l / h) with low power consumption;

- large diameter inlet;

- complete with angular adapter (90º) of universal type;

- pumping suspended particles up to 38 mm in diameter;

- the presence of a built-in float switch;

- variability of the installation (stationary, portable);

- minimum production noise;

- complete with combined nipple for standard hoses;

- guarantee of long-term and simple operation.

Among the negative sides of the aggregates, the impossibility of all models to cope with sedimentary rocks of large sizes can be distinguished.