Setting up a well in a private area involves the use of a good pumping station. With its help, it is possible to ensure a continuous supply of water to the system and maintaining a stable pressure in the line. The main thing is to properly connect the pumping station to the well.

Preparatory stage

Before you start the device pumping station, you need to carry out several preliminary stages of work.

Equipment Type Selection

For wells in the sand up to 20 meters deep, you can take a surface pump. He is able to raise water from a level of up to 9 meters. You can increase the performance of the unit with a remote ejector. In this case, water will be taken from a depth of 18-20 meters, but with less power equipment.

For deep wells, you should buy a submersible pump. Best deepest. The device has the form of a flask, which is placed in the casing a meter from the bottom. The Danish Grundfos pump has excellent characteristics, the price of which varies depending on the depth of immersion.

The rest of the equipment is selected according to the following technical parameters:

- power;

- performance;

- pressure;

- cost.

Pump performance should not exceed well performance. Otherwise, the mine will quickly become empty and slowly fill up.

Pipe selection

For the installation of water supply, you need to purchase pipes on the external and internal trunk. It is better to lay the external line with the help of PND products. They are not afraid of temperature changes, static and dynamic soil pressure. They have a smooth inner surface, which ensures a normal flow of water.

It is better to lay polypropylene pipes inside the house. Their installation is performed by soldering. As a result, the molten polymer forms a perfectly tight joint.

Placement Selection

It is better to connect the water station to the well as close as possible to the hydraulic structure. There are several main places where you can install equipment:

- Basement of a private cottage. It is always dry, moderately warm. Do not have to spend money on the device of the technical room and its insulation. But it is important to remember that a working pump station emits very loud noises, which can cause discomfort to the residents of the house. You will need to soundproof the basement in order to install discharge equipment in it.

- Caisson. This is a special protective chamber located at the very tip of the well. The caisson is convenient in that it completely isolates all residents of the house from noise, protects equipment from atmospheric precipitation, cold, and vandals. With the camera, you can not be afraid that moisture will have a negative effect on the walls of the basement, even if we are talking about condensate.

There are several important principles that should be followed when choosing a place for the installation of a pumping station:

- It is advisable to mount the equipment as close to the source as possible.

- Access to technology should be free all year round.

- It is important to provide good ventilation.

Most masters still prefer a caisson. In addition, under certain conditions of its installation and laying of the pipeline, it is possible to save a little on consumables.

Station Connection Options

There are two ways to connect a pumping station to a pipeline:

- Through the downhole adapter.This is a device that is a kind of adapter between the intake pipe in the source shaft and the water pipes outside. Thanks to the downhole adapter, it is possible to draw the line from the hydraulic structure immediately below the freezing point of the soil and at the same time save on the construction of the caisson.

- Through the head. In this case, you will have to take care of high-quality insulation of the upper part of the source. Otherwise, in freezing temperatures, ice will form here. The system will stop working or break in one of the places.

To connect the pumping station to the well, you need to use only high-quality fittings, fittings, sealant. Otherwise, leaks are not ruled out in the system.

Installation and Connection Stage

Begin the installation of pumping water equipment with a pipeline device. For the outer line, it is worth digging trenches according to a pre-drawn plan. The depth of the channel is below the level of freezing of the soil. If this is not possible due to the features of the terrain or the high level of groundwater, provide high-quality insulation of the highway. It is better to use polystyrene shells.

At the entrance of the pipeline into the house, a technical hole is made in the foundation with the help of a perforator crown. The gap is reinforced with a steel sleeve. All gaps are carefully sealed and insulated. It is the entry of the main into the house that can become that bridge of cold, which in the future will lead to freezing of water in the system.

The internal wiring of the line is done in a sequential or collector way. The first option involves branching the pipe to each plumbing fixture from the main line. The consumption of materials is minimal. But the pressure in the water supply will be unstable with the simultaneous opening of two or more taps. Collector wiring provides a good head regardless of the number of working plumbing points, but leads to cost overruns.

Backfilling of the external water supply is performed without compaction of the soil. They just pour it as it sags.

Submersible equipment

The connection diagram of the pumping station to the well for a private house with a deep pump is relatively simple. If a downhole adapter is used, the work is performed as follows:

- A water-lifting hose is fixed to the outlet pipe of the deep pump. Do this with a fitting. The length of the hose should correspond to the height of the casing from the point of placement of the pump to the inside of the downhole adapter.

- At the same time, the power cable and safety cable are stretched on the ground. To avoid tangling in the casing, all three elements are pulled together with building clamps in increments of 1 m. It is important to avoid tension or sagging of at least one of them.

- In the casing below the level of freezing soil make a technical hole for the adapter output.

- A water supply hose coming from the pump is fixed to the back of the adapter. The unit is carefully lowered into the source shaft and with the help of a special key the adapter element is inserted into the hole made.

- Outside it is adhered to the second part and tightened well.

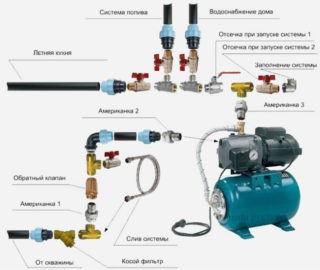

- At this stage, the installation of the pumping station (hydroaccumulator, manometer, pressure switch) is carried out. The tank must be securely fixed by pulling it to the base with anchor bolts.

- A pipe is connected to the inlet pipe of the accumulator, which extends from the outside of the downhole adapter. Before entering the tank, a check valve is mounted. It will prevent the outflow of water from the drive.

- A water supply line is pulled from the outlet of the tank, installing another non-return valve one meter from the tank. All joints must be connected using sealant.

If the pump station is connected through the head, the water supply hose is discharged through its upper part, and the safety cable is attached to the carbine on its inner side.

Surface pump

The sequence of connecting a pumping station to a surface pump looks like this:

- The unit and the accumulator are placed close to each other.

- A water intake hose is connected to the pump inlet. A coarse filter is put on its end.

- The pipe is lowered to the desired level of the shaft.

- The hydraulic accumulator and the pump are interconnected by a pipe segment equipped with a check valve.

- The next point of the phased connection of pumping equipment is the installation of the main water supply line.

Start up equipment is never performed dry. First you need to pour water into the accumulator and pump through special technical holes and only then allow the unit to pump.

Power on station

At the initial start-up of the equipment, it is necessary to adjust the working pressure of the accumulator. For the lower parameter, an indicator of 1.5 atm is optimal. For the upper boundary - 3-3.5 atm. With these parameters, the pump is fully connected and turned off, ensuring the normal operation of the system.

Pressure is regulated by a manometer and a relay. The handles are twisted along the arrows indicated opposite them.

If, after adjusting the pressure, the pumping station works without failures, there are no leaks at the joints, then you can backfill the trench of the external water supply.

The control unit is placed in close proximity to the pump and hydraulic tank.

Common mistakes

When installing a pumping station, masters can allow such flaws:

- Lack of check valves at all inputs to the equipment. From this, the water will constantly flow back, which will lead to incorrect operation of the station.

- Lack of pipe length margin. It is worth considering all the turns of the highway, the inputs to the house. It is better to take a section with a margin than to increase the number of connections or the number of consumed pipe sections.

- Docking threaded fittings without a key. Even if a master of remarkable strength, it is better to tighten the elements with a special tool. Otherwise, line depressurization may occur.

- Lack of pressure control for the accumulator. It leads to excessive consumption of electricity, combustion of the pump, unstable pressure in the water supply.

- Ignoring the filtering system. Well water requires good cleaning. Even if visually it is completely transparent. The type of filter is selected after laboratory analysis. The most optimal are reverse osmosis plants, the separation of the flasks for which allows several stages of liquid purification to be performed at once. Connect such filters under the sink with the conclusion of a separate faucet for drinking water.

Subject to all the above recommendations, the master can independently connect a pump station for the Abyssinian well (hole-needle) in the country or a source to the sand.